Any discussion of sound control in the context of mass timber has tended to concentrate on noise issues – how well or otherwise these products and systems perform in the reduction of sound transmission. Arguably, much less attention has been afforded to the question of acoustics and the sculptural opportunities for architectural control of sound diffusion that are achievable with mass timber through the use of parametric design and robotic fabrication. Recent work on the room acoustic potentials of cross laminated timber (CLT – supplied by Element5) by Dr. Brady Peters and his team at the John H. Daniels’ Faculty of Architecture, Landscape and Design at the University of Toronto hints at exciting ‘sound scattering’ possibilities. Successful further development of this research could well prove to be a game-changer for those involved in the interior design of theatres, recital and concert halls as well as large scale auditoria and who wish to take advantage of the many environmental and constructional benefits offered by engineered timber products.

We visited them in Toronto and their laboratory blew our mind!

Author

Brady Peters, PhD - Assistant Professor

John H. Daniels Faculty of Architecture, Landscape and Design

1. Performance, Architecture and Computation

When architects talk about performance we are usually referring to how well a building functions in relation to some metric: structural performance, energy performance, acoustic performance, etc. It is inevitable that all buildings “perform” to some degree, after all, all buildings have structure, light, air, and sound. If given the option of a design performing better or worse, architects would almost certainly choose better. And why not, to design well-performing buildings is usually what we are striving for. While shelter is one our essential needs as humans and one of the primary aims of architecture, most architecture aims to do more than merely shelter, but create space that has cultural meaning and social significance, and has a considered and designed atmospheric experience (see note 1).

Over the last decades, the practice of architecture has shifted from the use of analog drafting boards to the use of digital design technology, and this has meant an increased use of parametric design, building information modelling, and qualitative performance-based simulation. Architects are natural simulators, intuitively using different methods of drawing and modelling to predict aspects of tectonics, performance, or experience; and, simulation’s time-based nature promotes understanding buildings as ever-changing states instead of singular solutions. Architectural designs no longer exist as a static set of two-dimensional drawings, but as a set of live, linked, computational algorithms. Architects are leveraging computational tools and cross-disciplinary expertise to innovate new building designs and building technologies.

2. Old Materials Are New Again: The Potentials of Mass Timber

Timber has been used in architecture for millennia, and is certainly nothing new in architecture; however, in recent years, technological advances in gluing, fixing, and manufacturing have allowed new timber products to be used in bigger and more complex building projects. This new timber technology, called “mass timber”, is a family of products made by connecting a series of smaller timber elements together to form larger panel or beam products. Canada is updating its building code to reflect these advances and allow larger and taller all-wood buildings (see note 2).

This rise in timber also comes at a time when we are beginning to realize the many large and hidden environmental costs of our dominant building materials, in particular that of concrete and of steel, and this has led to the pursuit of more sustainable alternatives. In terms of carbon, forests store vast amounts of carbon, and buildings constructed of wood continue to store it. So, if the built environment is to be carbon-free by 2050, architects must use lower embodied carbon strategies, or use carbon sequestering materials such as mass timber (see note 3). Timber is a renewable resource that can be sustainably harvested. Living and working in Canada, timber is a local material requiring less energy for transport.

3. The Rise of the Robots: Digital Fabrication and the Building Industry

As architects we are interested in seeing our designs constructed, and the adoption of new digital design technologies may give us tools to more easily make this happen. Digital fabrication enables information to be sent directly from our design software to a fabrication machine. This “file-to-factory” approach has the potential to revolutionize the building industry – an industry where productivity is actually decreasing and the uptake of new technology has been slow (see note 4).

3D printers and CNC machines are examples of digital fabrication machines that have already revolutionized the architect’s design process; however, it is robots that may yet revolutionize the building process. In the last decade architectural researchers have begun to experiment with using industrial robots to expand the role of digital fabrication in the building design and construction process. As architecture is a design process that extends from ideation through to realization, the introduction of robotic fabrication requires new innovations and a re-thinking of design process. In the building industry, design tool innovation has been hindered by a tendency to digitalize already existing processes instead of harnessing the inherent potentials of computational technology.

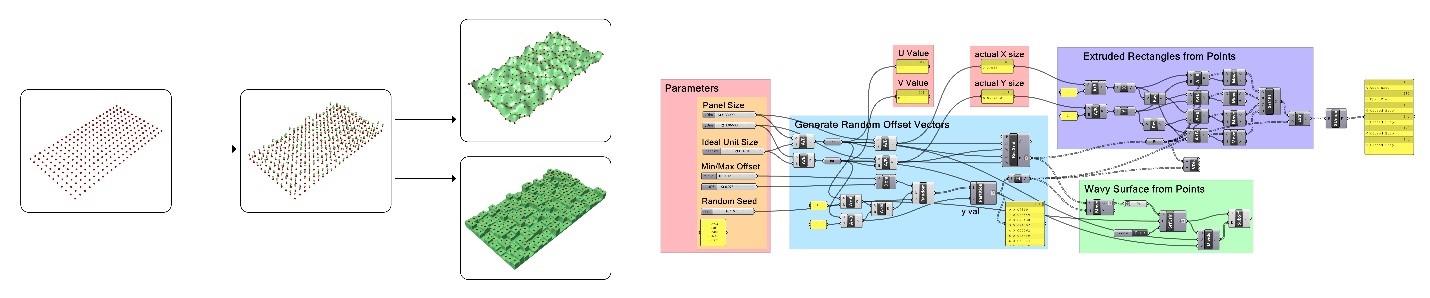

At the John H. Daniels Faculty of Architecture at the University of Toronto we have set up a Robotic Prototyping Laboratory. The research that we are engaged with has as one of its broader goals – the investigation of the potentials of robotic fabrication for architectural design and construction processes. The lab supports the research of Dr. Brady Peters, and is funded by the Canadian Foundation for Innovation (CFI) and National Science and Engineering Research Council (NSERC) Discovery program. The lab has a Kuka KR150 R2700 Robot with KL4000 linear axis, a PushCorp STC 1515 water-cooled with 10hp servo spindle, a 10-bay rack for endmills with auto tool-change capability, automatic laser calibration for milling endmills, a Schunk auto-tool-change (ATC) system for end-effectors, a 3-bay rack for end-effectors with auto-tool-change capability, a Schunk PHL pneumatic gripper, a Schmalz FX-SW vacuum gripper, and we are developing several custom end-effectors for projects such as a custom pneumatic saw table. The lab has a space that is 8.8m by 9.8m with an approximate 8m ceiling height.

The lab’s current research into the acoustic potentials of shaped CLT panels is supported by material donations from Ontario mass-timber manufacturer Element5.

5. The Room Acoustic Potentials of Mass Timber

As Mass Timber panels are produced in controlled factory conditions, and, when installed, are often left exposed to showcase the natural beauty of the wood. This opens the potential for surface treatments to be done in the factory that will impact acoustic performance. While some research has been done on the acoustic properties of mass timber, much of this focuses on building acoustics and sound transmission (see note 5).

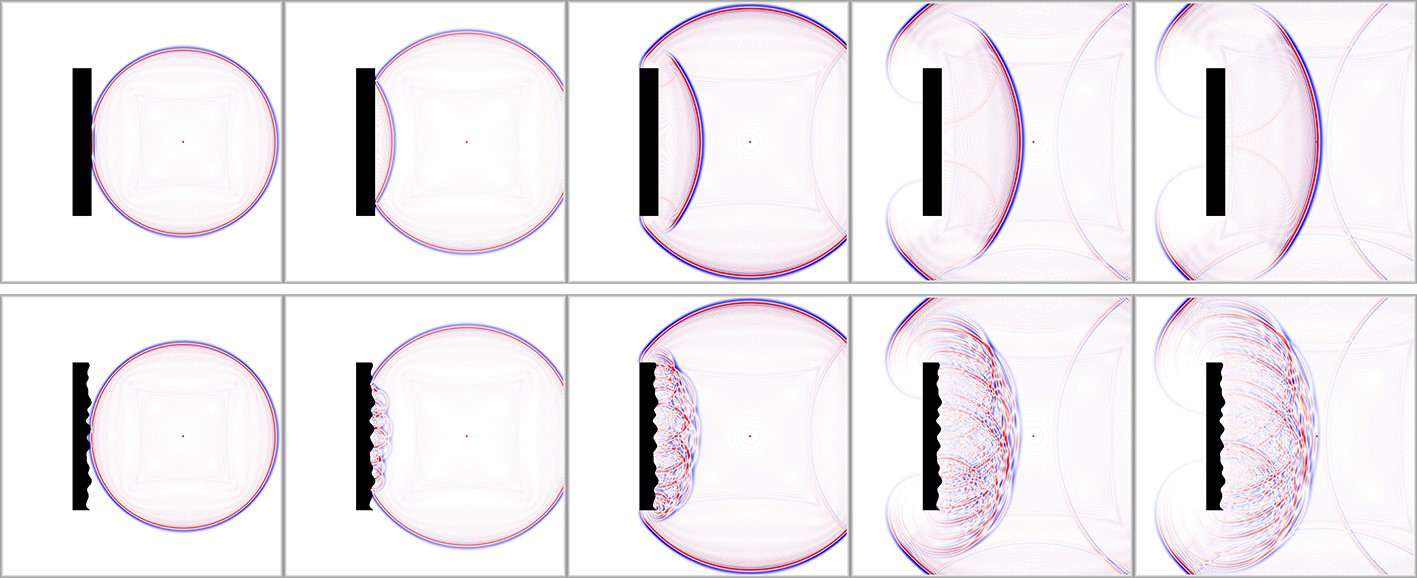

The work we are currently engaged in studies the potentials of mass timber walls and ceilings to be carved with geometric patterns that not only add to the aesthetic qualities of the space, and express the material qualities of the wood, but also add to the room acoustic performance through improving sound scattering. Sound scattering surfaces have been proven to benefit performance spaces such as concert halls, but also more common types of spaces such as meeting rooms. While it is recognized that sound absorption is still a necessary component to any room acoustic solution, sound scattering can improve the acoustic quality through reducing distinct echoes, maintaining sound energy, and making acoustic absorbers work more efficiently. In our latest experiments, four different types of surface geometries were developed using parametric modelling, simulated using various computational methods, and prototyped at 1:1 using our robot. Our investigations study not only the improvements in performance, but also the aesthetic and constructive dimensions of the geometries.

Notes:

1. Brady Peters. “Architectonic Design and Computation in Performative Buildings,” in The Routledge Companion to Performativity in Design and Architecture, edited by Mitra Kanaai, Routledge Publishers, 2019.

2. https://canada.constructconnect.com/joc/news/government/2019/05/2020-nbcc-code-brings-new-era-canadian-wood-construction , accessed 3 February 2020.

3. Bruce King. New Carbon Architecture, New Society Publishers, 2017.

4. https://www.mckinsey.com/industries/capital-projects-and-infrastructure/our-insights/the-construction-productivity-imperative , accessed 3 February 2020.

5. Tim Praeger. “Understanding the Acoustical Challenges of Mass Timber Buildings,” in Construction Canada. https://www.constructioncanada.net/understanding-the-acoustical-challenges-of-mass-timber-buildings/ , accessed 31 January 2020.