Ergodomus has been designing Mass Timber Staircases for years. Stairs are not easy to be designed and we’re going to show you how we do it.

Stairs are not easy to be designed, we know that, but many different Mass Timber projects challenged us with this kind of design and we’re going to show you how we usually deal with it.

The first thing that comes to mind when you design a timber staircase is a common imagination: it often tends to associate timber with an idea of low strength and durability over time. Nothing could be more wrong, because timber is a material that ages very well, especially indoors, and can easily last for centuries.

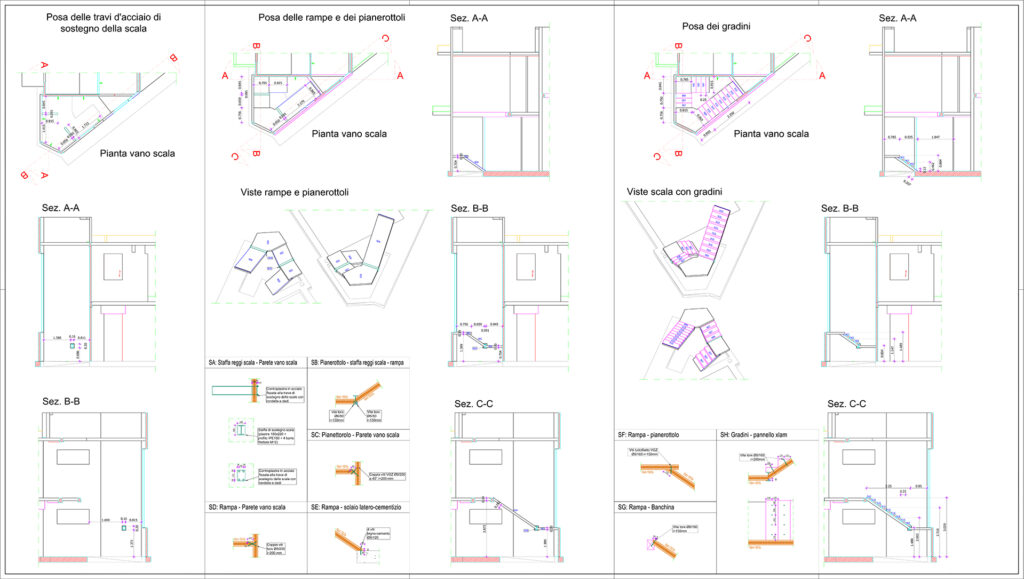

As mentioned above, in the past years, we gained a wide experience in engineering stairs made of timber. We learned how the engineered elements can be designed in our office and then machined somewhere else with a CNC machine according to our “WYDWYG” motto (What You Draw Is What You Get).

At Ergodomus we came up with the acronym WYDWYG due to our effort and commitment to details. No matter how complex and ambitious, each project we work on deserves to be studied in every single aspect and construction detail.

Our “obsession” with details has led us to work in 16+ countries engineering 300+ projects.

How many times have you spent hours on the construction site drawing the stair on the wall and at the end being worried about what the workers will do or asking yourself questions like “Will they understand my drawings? Better if I go to the site and stay there until they finish?”

How many times did you have to spend money and time to build a temporary stair (perhaps even quite unsafe) that had to be removed a few weeks or months later?

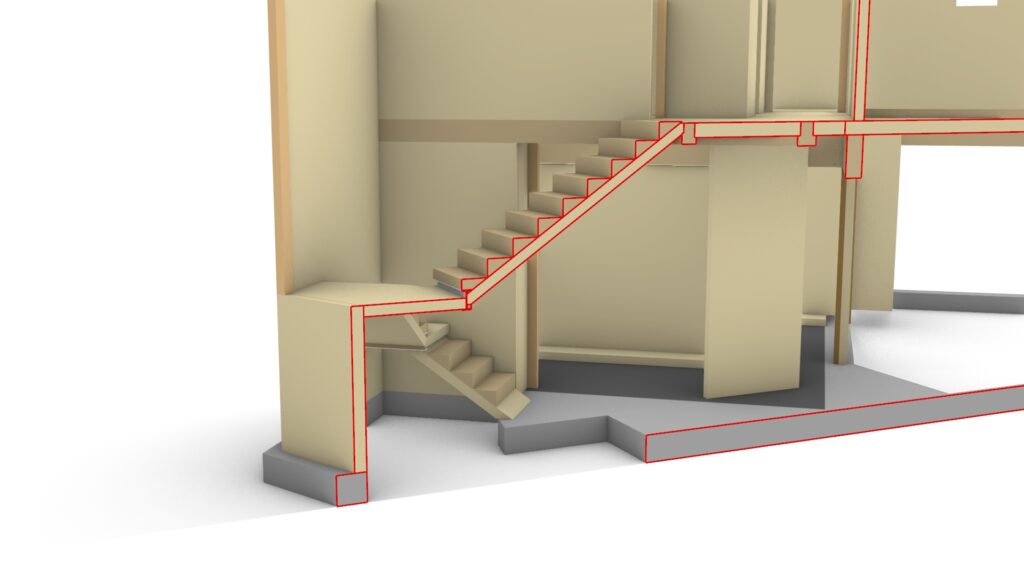

Timber stairs have several advantages starting from a faster installation time, in fact, they arrive on-site already pre-fab and can be assembled without the need for temporary scaffoldings. Moreover, wooden staircases have a lower carbon footprint compared to traditional materials and help to reduce construction waste.

You can use the stair immediately, just a few seconds after putting in the last screw, and, even better, during the time of construction. Furthermore, once the installation is complete, the stairs can be considered as a “final version” since they do not need any other work other than the eventual cover. Very simple! Isn’t it?

Timber staircases are a clear example of how timber can be used in a really smart way!

Last, but not least, consider the aesthetics: Staircases made of timber are extremely fascinating since they can be added to any type of environment, adapting perfectly to any style and design.

What about leaving CLT exposed? It could look outstanding!

Timber staircase projects we designed and engineered

In our rich portfolio, you can find a lot of environmentally conscious projects where you can find inspiration and some knowledge about timber structures.

Here below is a short list of projects with wooden stairs:

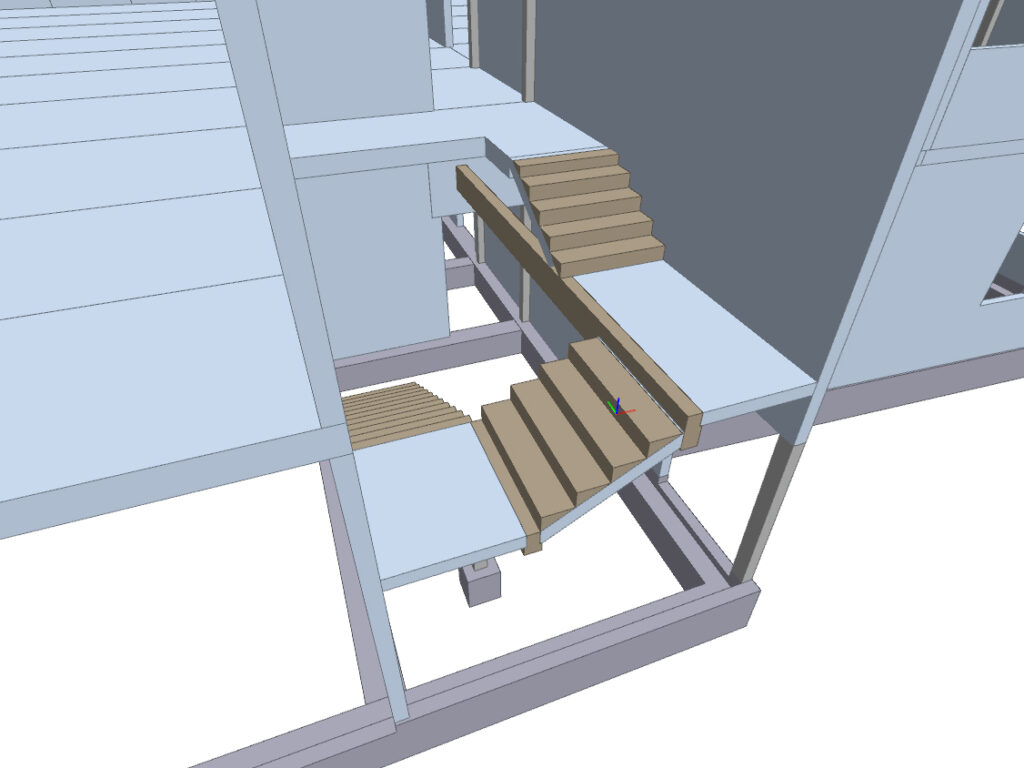

Vislab HQ

For this headquarter building, Ergodomus was involved in the project since the very early stage (the earlier we’re involved, the better it is). Our scope of work was value engineering aimed to find the most cost-effective solution and structural analysis, challenged by the seismic nature of the location of the structure. Moreover, we also prepared the production and assembly drawings (DfMA).

Every timber element for this project was prefabricated offsite, including the stairs, which allowed the HQ to be completed (only the timber structure) in just four weeks.

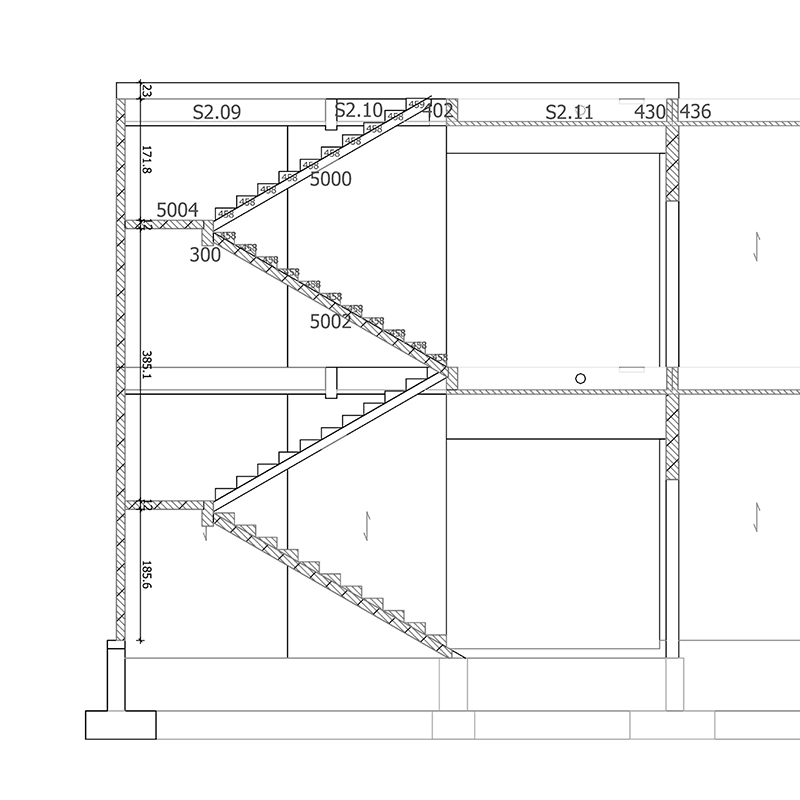

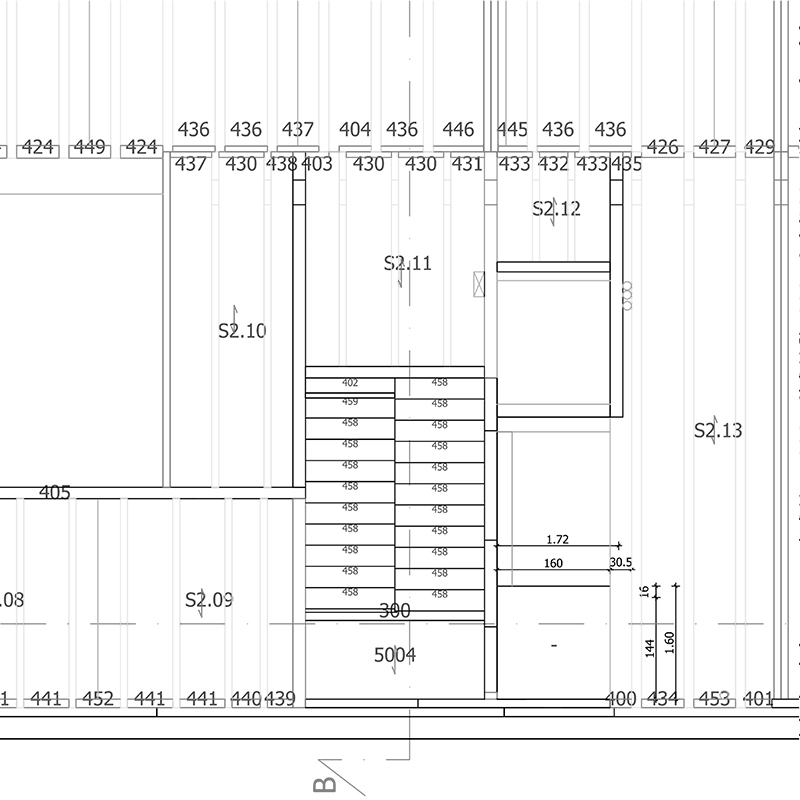

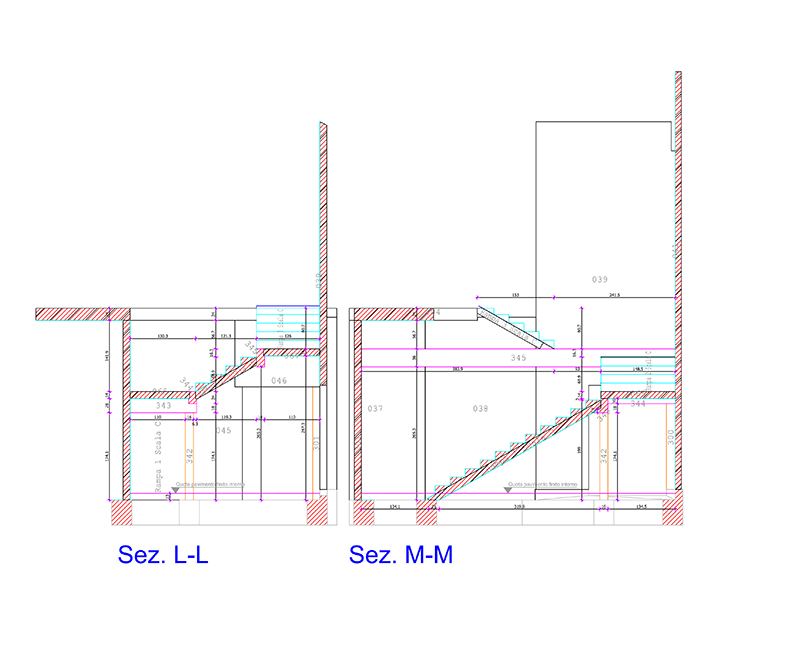

6-Storey CLT building

This building is located in the central area of Parma and it consists of six residential floors completely made of timber. A distinguishing characteristic of this particular structure is that, differently from other timber buildings, the elevator-stair shaft is entirely made of timber and not reinforced concrete. This means that, besides the indispensable steel connections, timber is the only main building material from the ground level.

Corima’s House

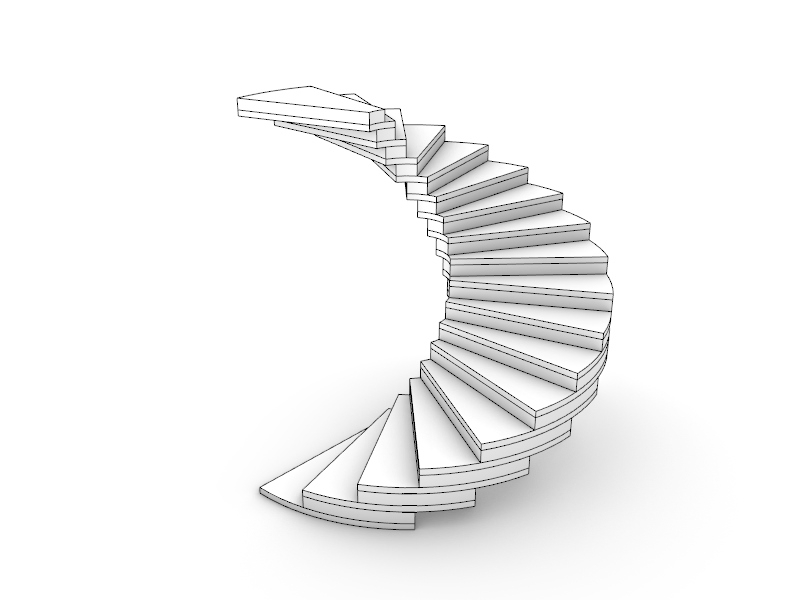

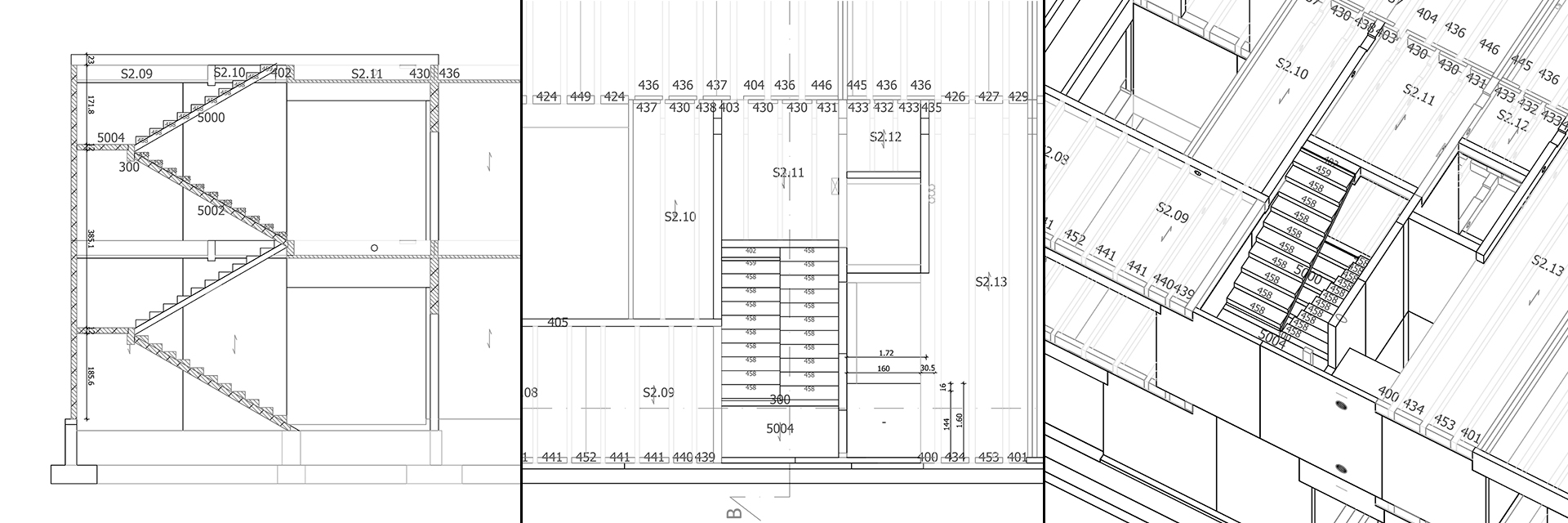

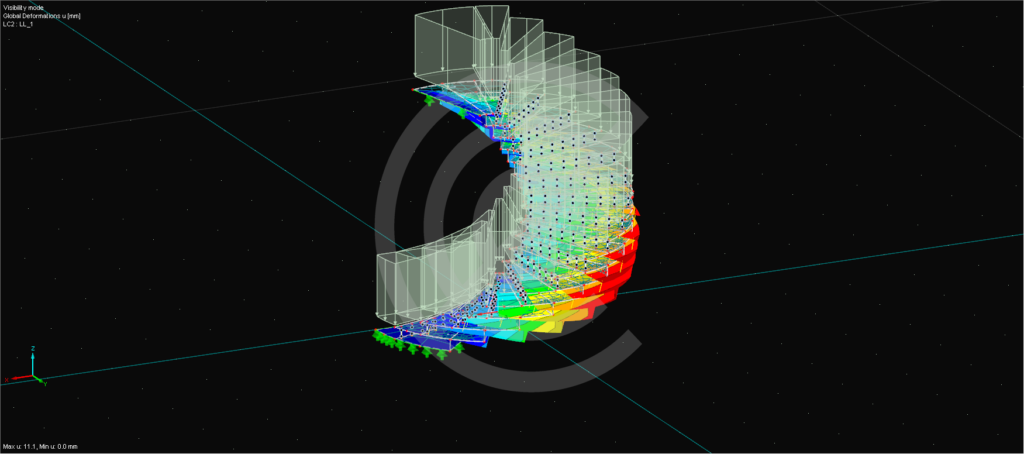

Project of a modular parametric staircase in CLT

At Ergodomus we developed this algorithm to create a parametric spiral timber staircase made up of CLT modules.

The interesting aspect of the algorithm is the direct connection with the software for FEM analysis, in this way it was possible to exchange information in a bidirectional way, allowing you to quickly size and optimize the position and number of pins.