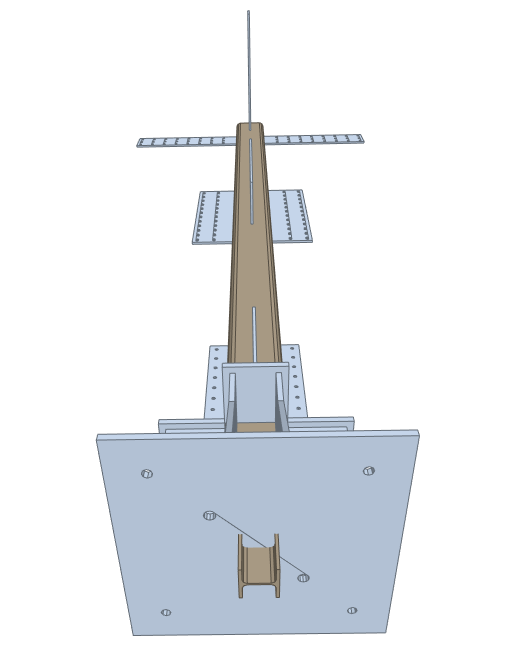

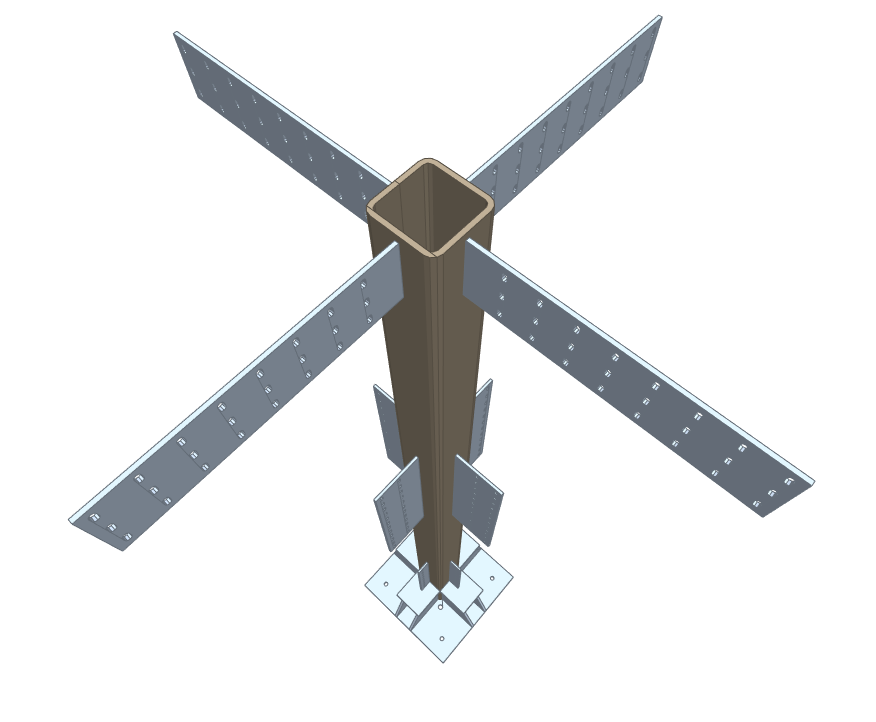

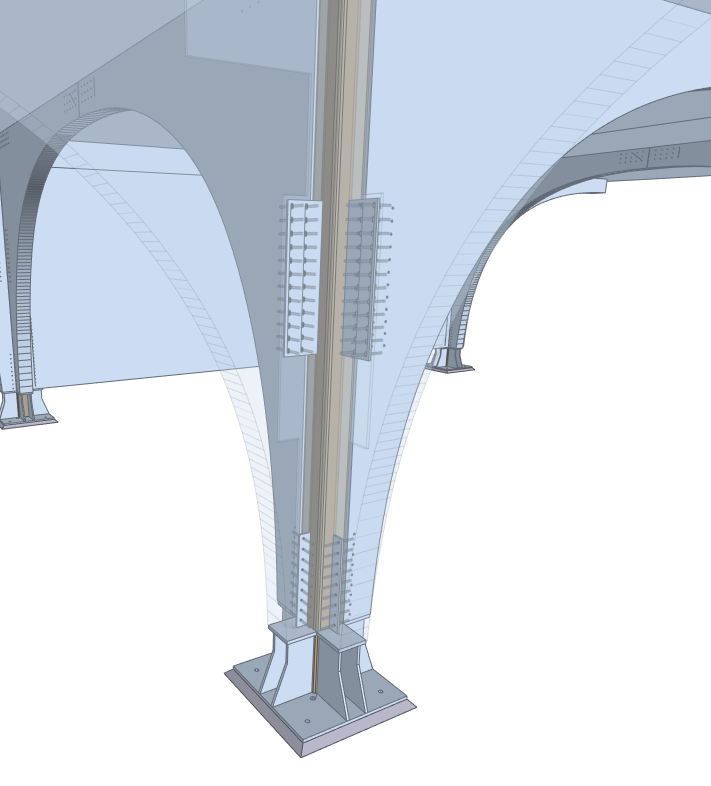

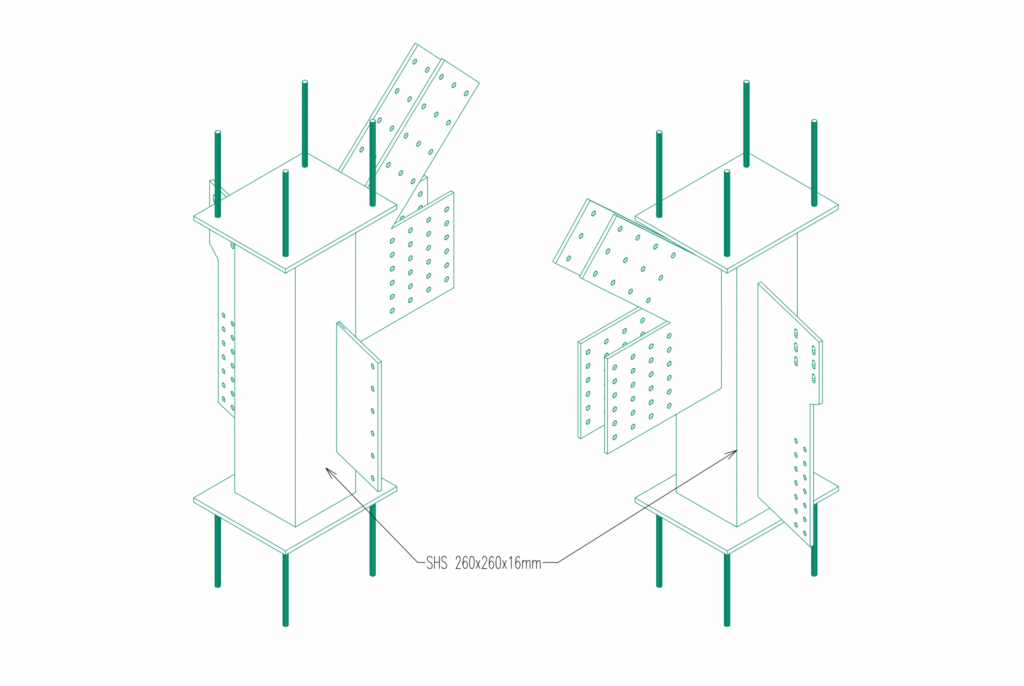

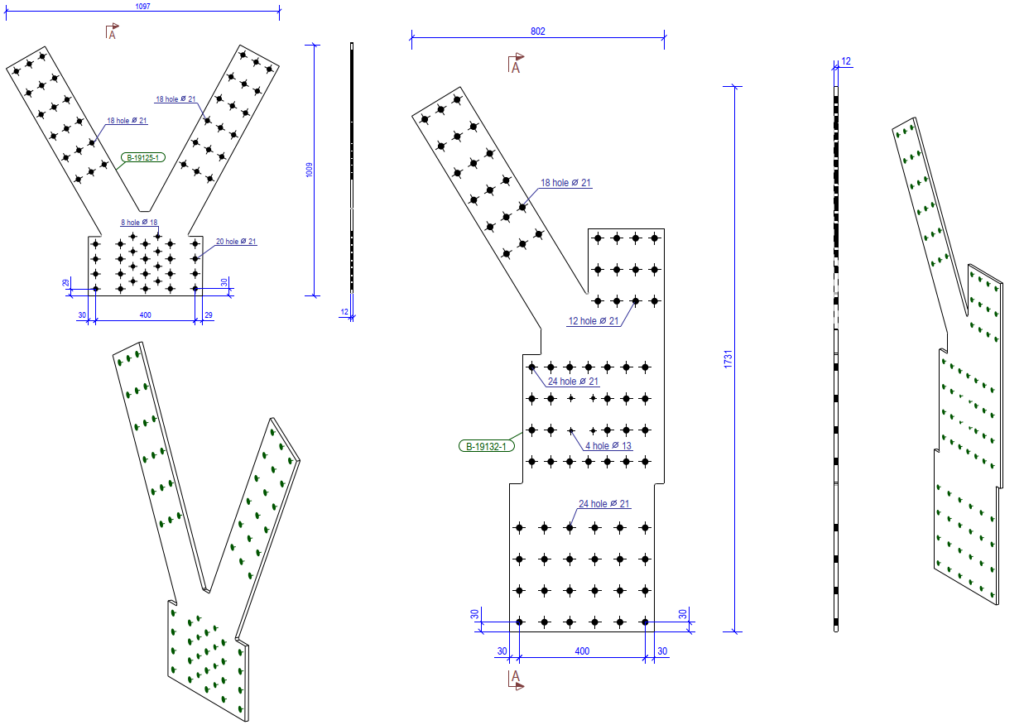

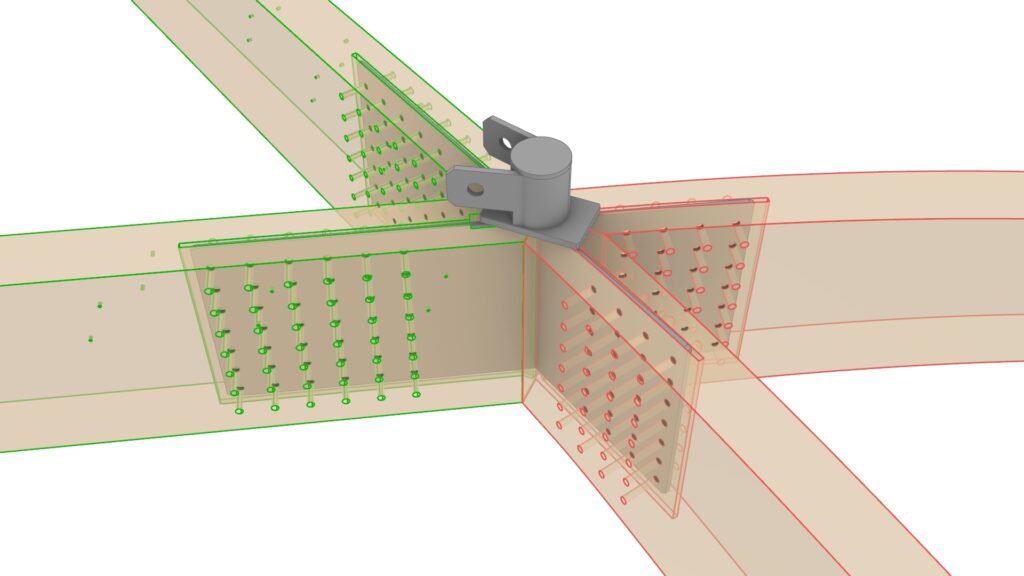

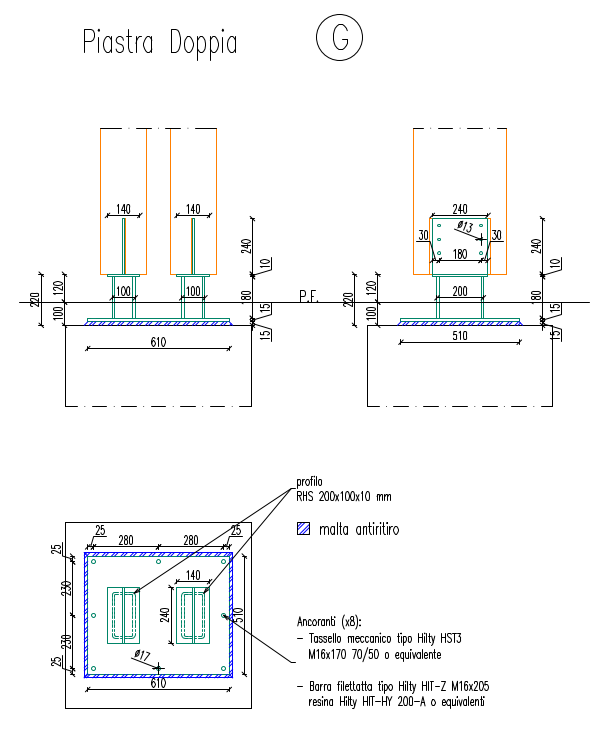

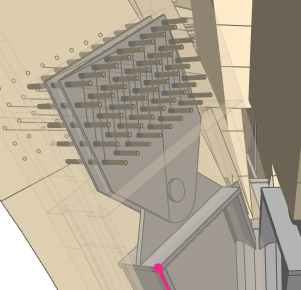

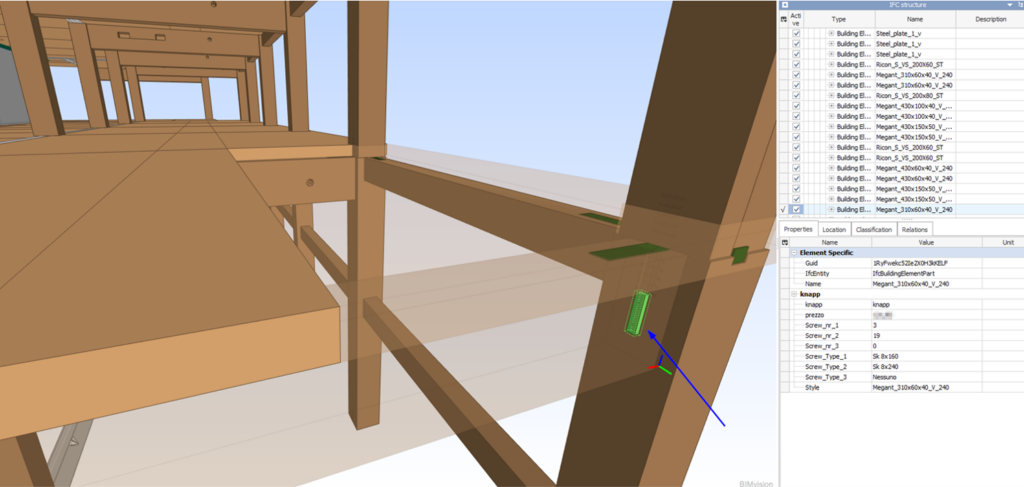

Detailing in timber engineering refers to the precise design and specification of every joint, connection, and element within a structure. It involves transitioning from broader design at larger scales (e.g., 1:50) to highly detailed plans at 1:1 scale, where even the smallest components, such as screws and bolts, are meticulously planned. Proper detailing ensures that timber elements fit together perfectly, are structurally sound, and are optimized for efficient fabrication and assembly.

It is crucial for all types of timber-based structural materials, including CLT (Cross-Laminated Timber), GLT (Glued Laminated Timber), LVL (Laminated Veneer Lumber), NLT (Nail-Laminated Timber), and DLT (Dowel-Laminated Timber). Each of these materials requires careful consideration in detailing to account for unique properties, such as load-bearing capacities, moisture management, and connection design.

In modern timber construction, detailing is closely linked with DfMA (Design for Manufacture and Assembly), ensuring that every component is practical for CNC machining and on-site assembly, minimizing errors, and maximizing efficiency.

This practice is crucial for us, to create beautiful and strong structures, so much so that one of our services is Detailing. Discover more here.