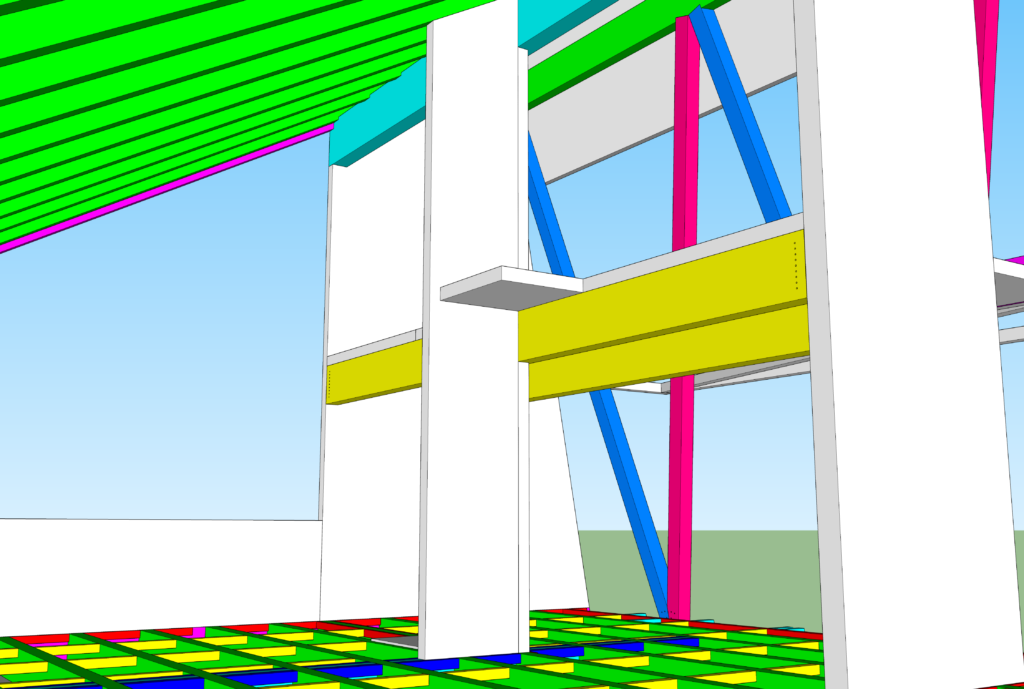

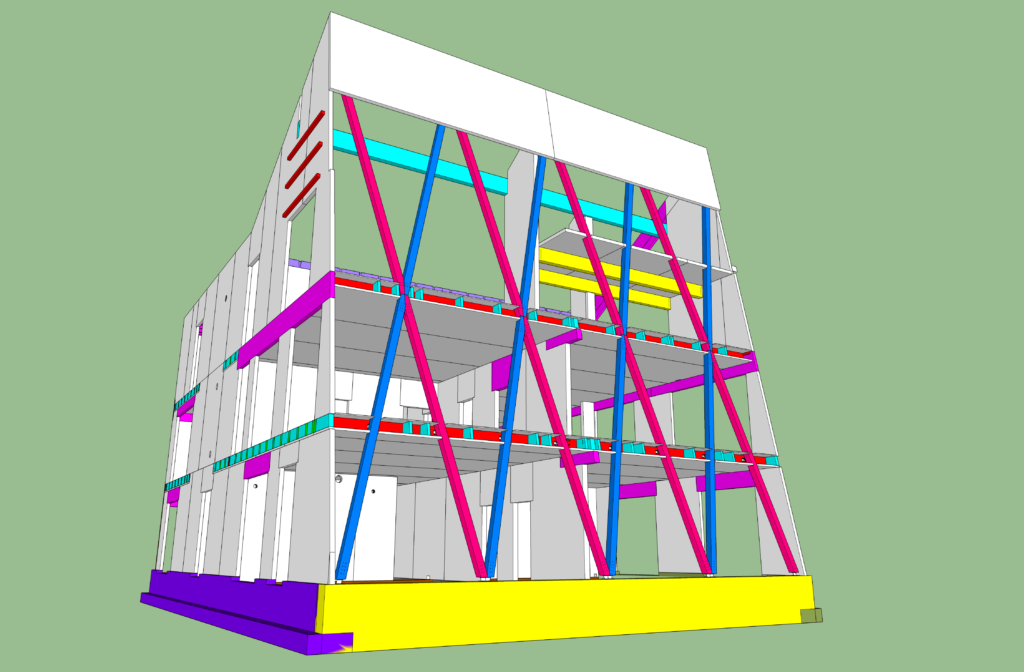

A Digital Twin is a precise 3D virtual model of a physical structure that mirrors its real-world counterpart. In timber engineering, particularly with the DfMA (Design for Manufacture and Assembly) approach, a Digital Twin allows for the creation of a highly accurate model of the structure long before any “real” components arrive on-site. This advanced model acts as an “as-built” representation of the final structure, providing a clear and detailed visualization of the project weeks ahead of its assembly.

At Ergodomus, we use Digital Twin technology to give clients a fully realized, highly detailed view of what they will receive on-site, ensuring that every component is precisely modeled for accurate fabrication and seamless assembly. This proactive modeling helps identify potential issues early, ensuring that the physical construction aligns perfectly with the virtual design.

A Digital Twin offers numerous advantages, including:

– Early detection of potential issues, reducing costly on-site modifications.

– Enhanced collaboration between all stakeholders, with a clear visual reference.

– Improved precision in manufacturing and assembly, as the 3D model is directly linked to production drawings and CNC files.

With Digital Twins, we bring the future of timber engineering into the present, ensuring efficient and error-free project execution.