Italy’s tallest mass timber building

In the heart of Latina, close to Rome, a revolutionary project is taking shape that will mark a turning point in the Italian urban landscape: the construction of Italy’s tallest Mass Timber building. At Ergodomus we are taking care of all the “timber” engineering aspects of this state-of-the-art structure, which represents not only a technical achievement, but also a concrete commitment to environmental sustainability. We work hand in hand with the other designers to create a project that combines innovation, inclusivity, ecology and a socio-cultural impact.

A project for the people, a sustainable future for Latina

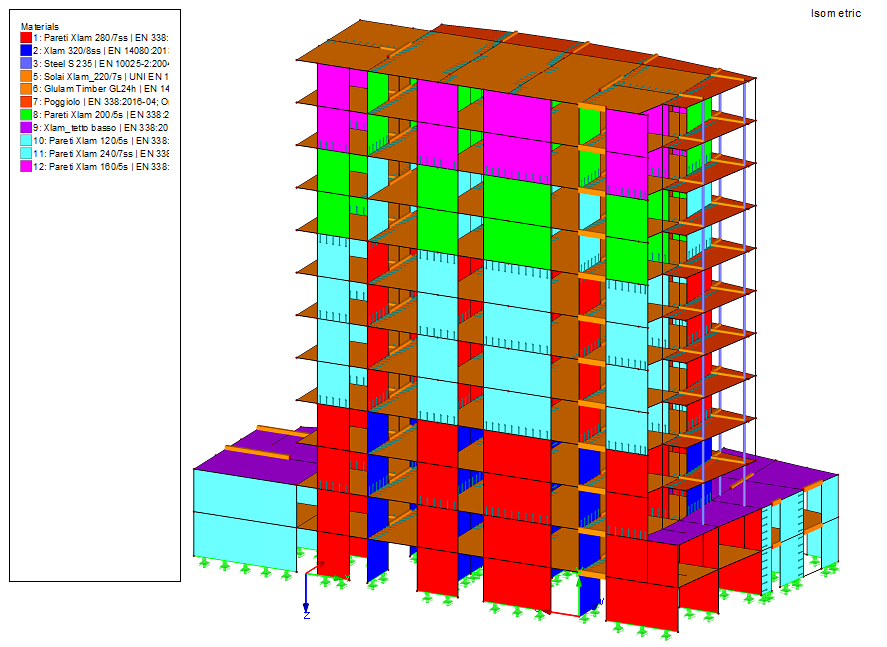

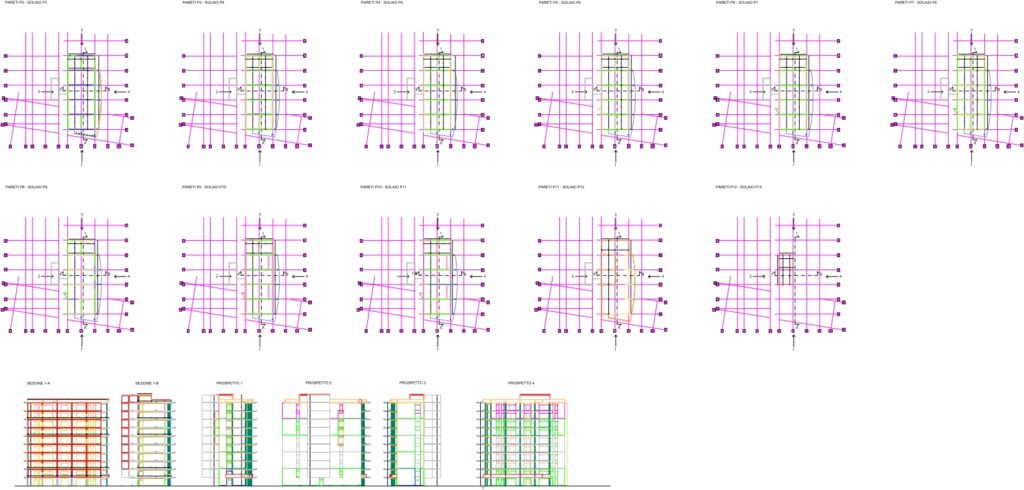

In 2021, a ministerial announcement opened the door to the urban redevelopment of an area of Latina with the “A Gonfie Vele” project. The collaboration between the designers and Ergodomus was crucial in overcoming the technical and design challenges. After months of dialogue and modifications, the result is a project that represents Italy’s tallest Mass Timber building, with its 11 storeys and about 40m, which will improve the area thanks to affordable housing.

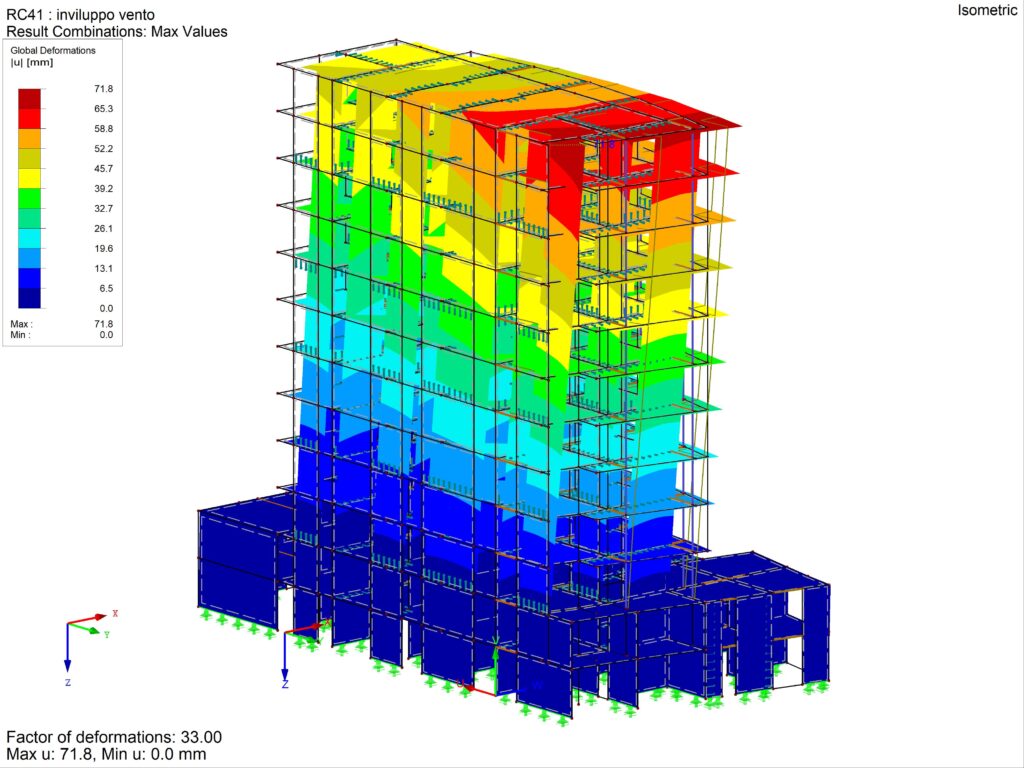

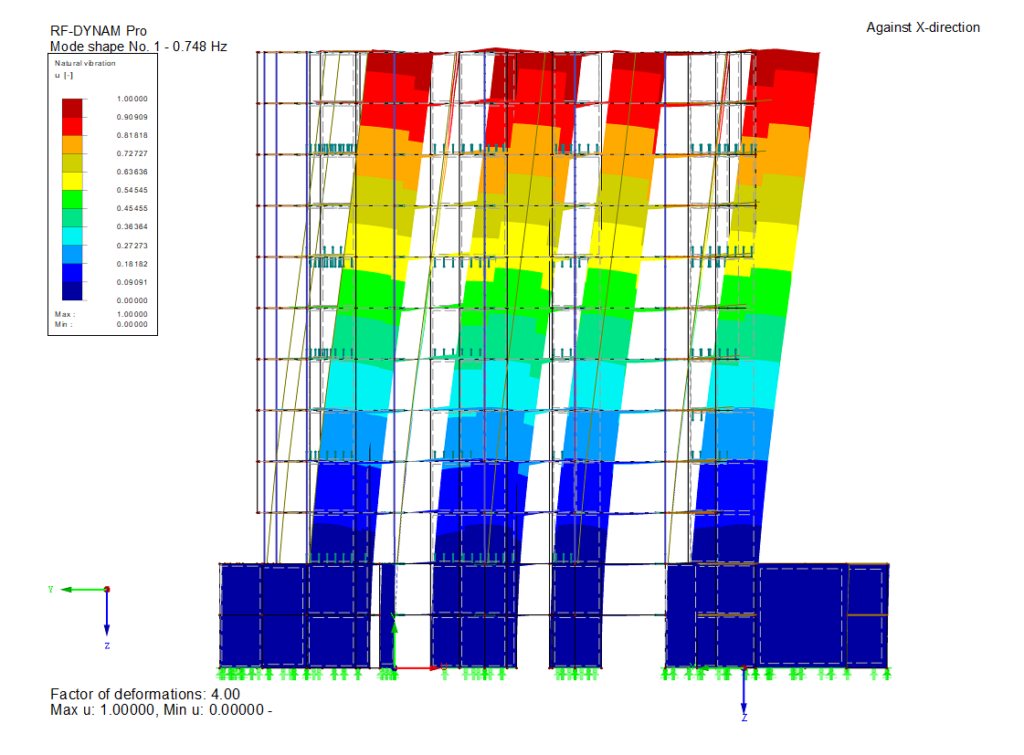

The Challenge of Tall Buildings: Wind

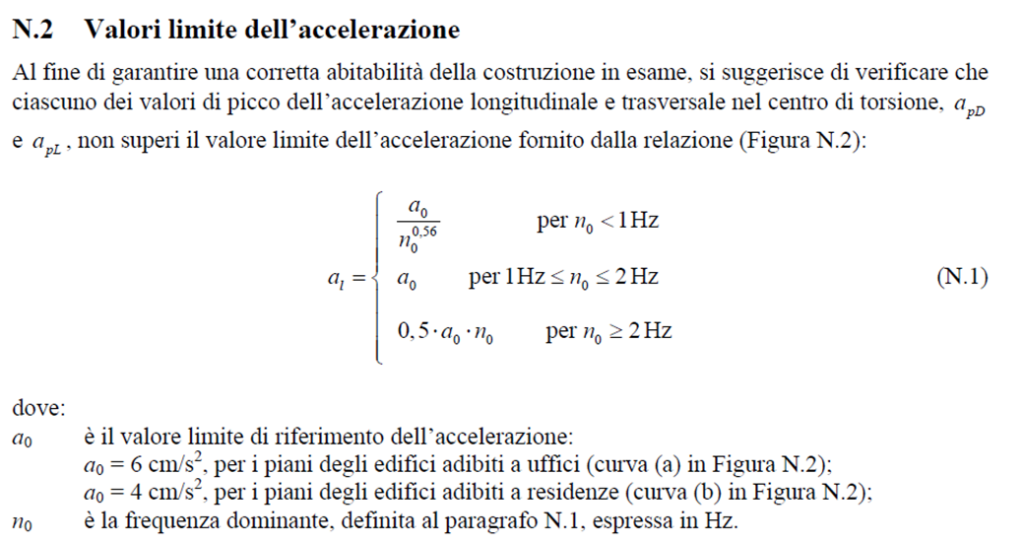

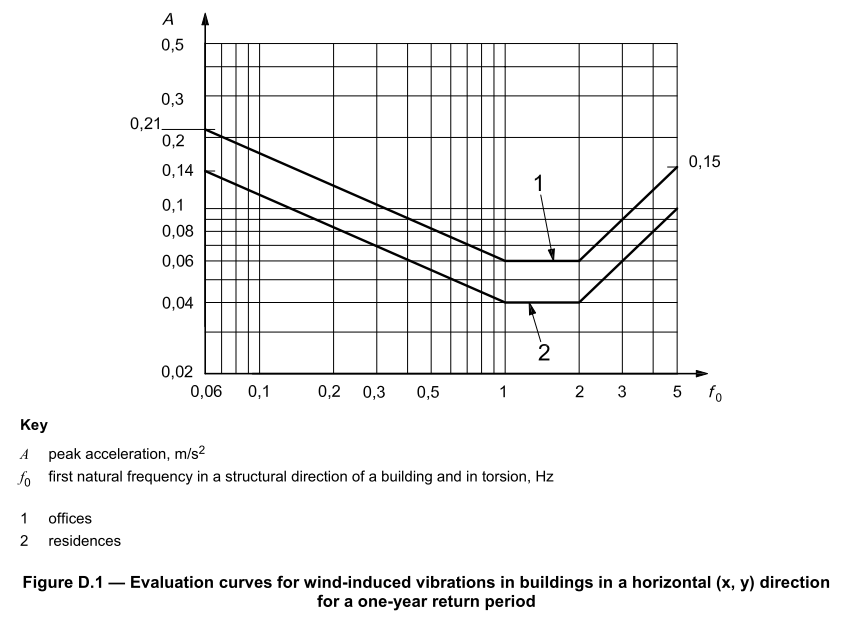

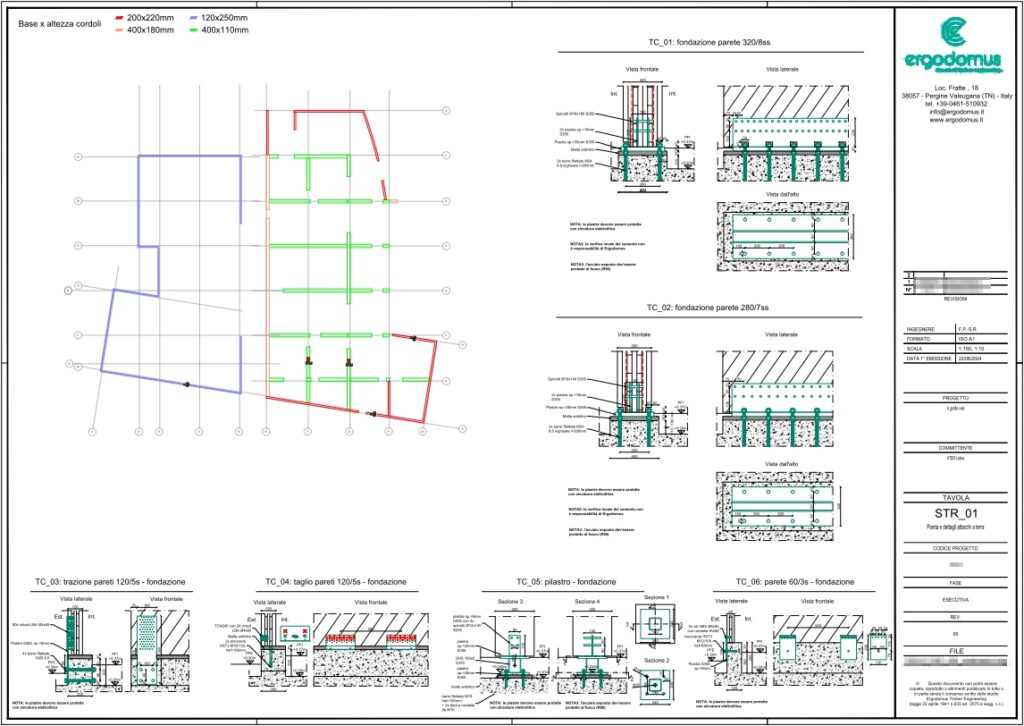

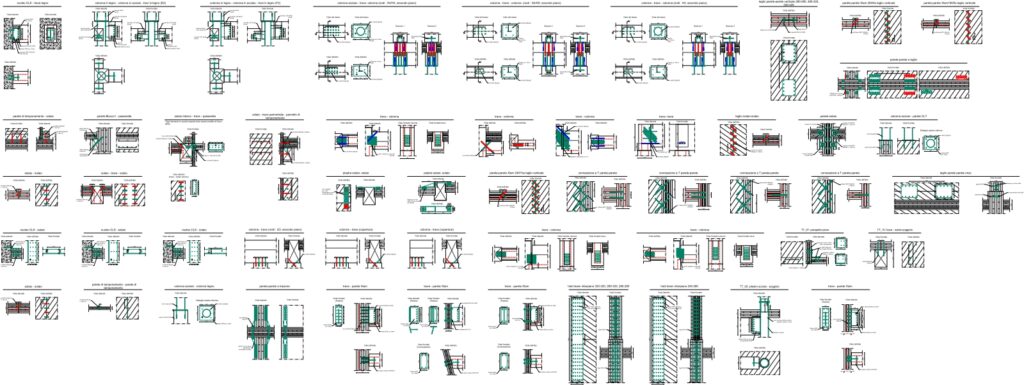

The uniqueness of this structure is its height but, being entirely made of timber, it has no concrete shaft serving as the lateral system. Due to this peculiarity, we had to conduct a deeply detailed analysis of the effects of wind and earthquakes on the structures. We also took into account the stiffness of each connection. These analyses revealed that, in this case, the design is driven not by horizontal deformation, but by the lateral acceleration due to the dynamic wind loads. To meet this comfort criterion and make people who inhabit the top floors feel at ease even during strong storms, we had to pour all our experience and creativity into designing bespoke steel connections.

Our “small” Secret

There’s a little secret that made Mass Timber the most cost-effective material for our latest project.

It’s something that has been around my mind for years, and finally on this project I had the chance to prove that it works.

Franco Piva

The seed for this idea was planted many years ago in the mind of our director, Franco. Once we realized the numbers were right, the excitement in our studio was palpable. From day one, we worked closely with the designers team, making this project a perfect example of our design assist service. This process was guided by critical factors like cost, aesthetics, and architectural needs, seamlessly combined with our expertise in structural analysis and production drawings. Drawing on over 20 years of experience in the timber and building industry, we employed a holistic approach to navigate the project’s complexities. This comprehensive method proved essential, as without it, the project would not have achieved the same level of success.

This proves once more that the Mass Timber experts must be involved immediately to reduce costs and ensure that Timber will be the right material to go for. Stay tuned for more updates on this project in the coming months.

Look at the 3D Digital Model we made

We shared this Digital Model via Speckle

Mass Timber’s role in Sustainability and Innovation

Uno dei requisiti fondamentali dell’appalto era la sostenibilità. Per soddisfare questa richiesta, il progetto incorpora la costruzione in legno, nota per le sue ridotte emissioni di CO2 durante la produzione. I benefici ambientali vanno oltre il completamento dell’edificio. Il legname utilizzato per la costruzione sarà reintegrato piantando nuovi alberi, promuovendo la riforestazione nelle aree in cui è stato raccolto il legname di massa. Questo ciclo di rinnovamento contribuisce a sequestrare altra CO2.

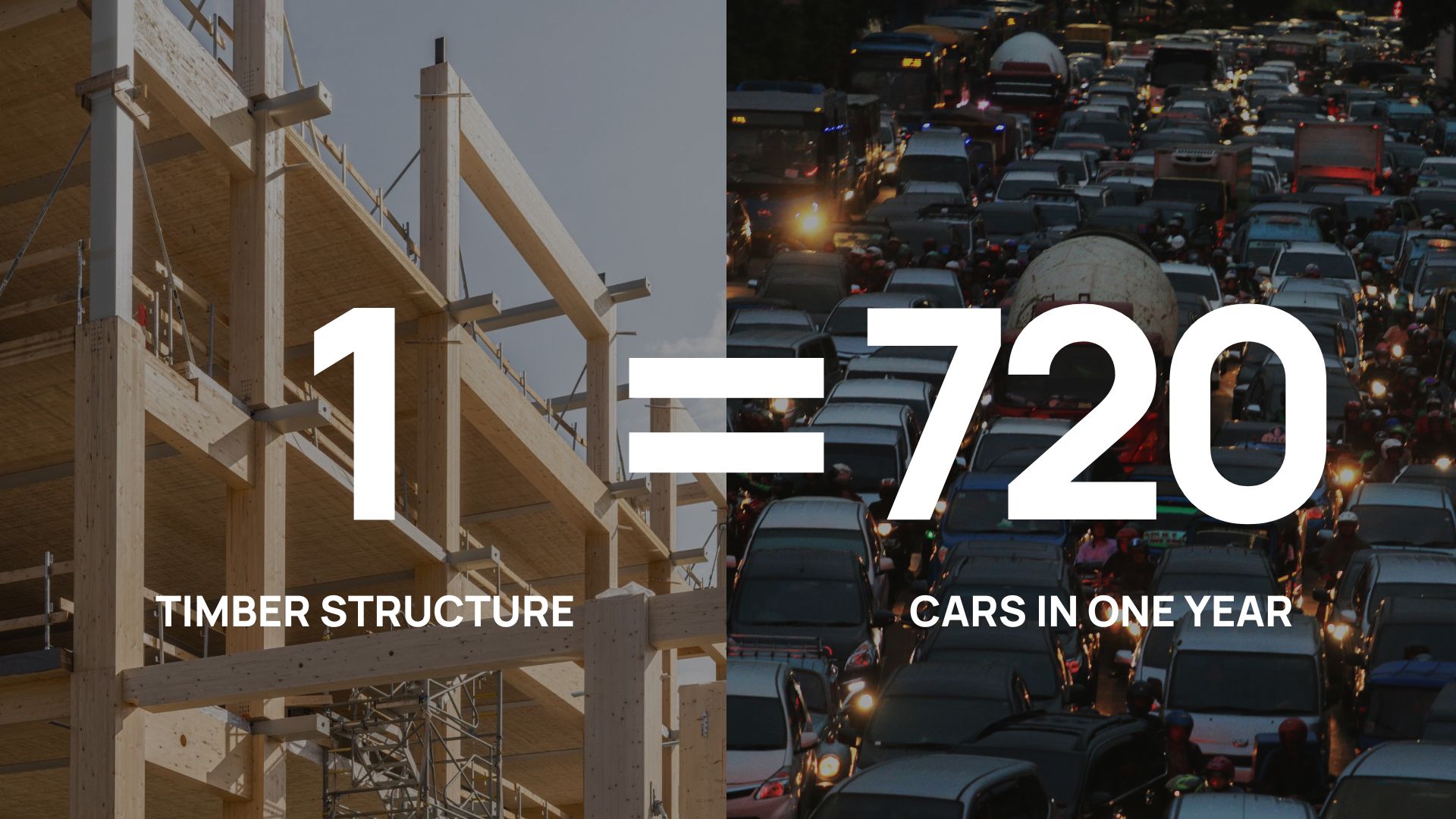

One of the pivotal requirements of the tender was sustainability. To fulfill this demand, the project incorporates Mass Timber construction, known for its lower CO2 emissions during production. The environmental benefits extend beyond the completion of the building. The timber utilized in construction will be replenished by planting new trees, promoting reforestation in areas previously harvested for Mass Timber. This cycle of renewal helps sequester more CO2.

The amount of CO₂ captured by this structure is approximately 2,000 tons. To help visualize this figure, we’ve compared it to something familiar: cars. A typical European car emits 2,000 tons of CO₂ after traveling 18.5 million kilometers. An average European car covers 25,000 kilometers per year, so the CO₂ stored in the structure is equivalent to the emissions of 720 cars! It’s a remarkable achievement.

Opting for Mass Timber not only signifies a step forward in building technology but also demonstrates commitment to ensuring a more sustainable future for generations to come. (Click here to read an article about Timber’s CO2 sequestration)

Environmental and Socio-Cultural Benefits

The project promises not only to transform the urban appearance of the area, but also to bring significant socio-cultural benefits. Green spaces and the use of wood as the main material will create a welcoming and healthy environment for the local community. The new facilities will include: a senior citizens’ centre, a police station, the local health authority, a biblio-bar, subsidized housing, a multi-purpose social centre, ground and underground parking, study rooms and co-working spaces.

This urban regeneration project is an example of how innovation, sustainability and collaboration can transform a community. Thanks to the use of Mass Timber, Latina will have a new face, greener and ready to face the challenges of the future.

As written in Il Sole 24 Ore, a known italian newspaper, work is about to begin! We will update this page with further information on the project’s progress. Stay tuned!