Pioneering Timber Engineering in Seismic Zones

In the heart of Modena, situated in the seismically active Po Valley, stands a groundbreaking 6-storey residential building entirely crafted from Cross-Laminated Timber (CLT). At the time of its construction, it was one of the tallest timber structures in Italy, symbolizing a significant advancement in mass timber construction within high seismic zones.

Early Collaboration, BIM Innovation, and Comprehensive Control

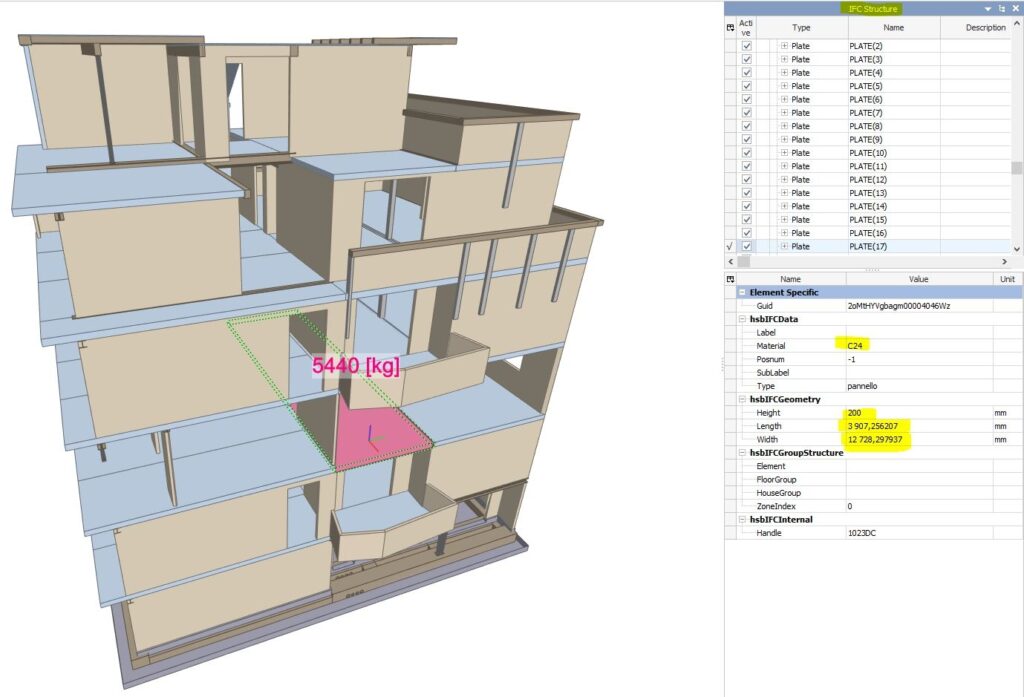

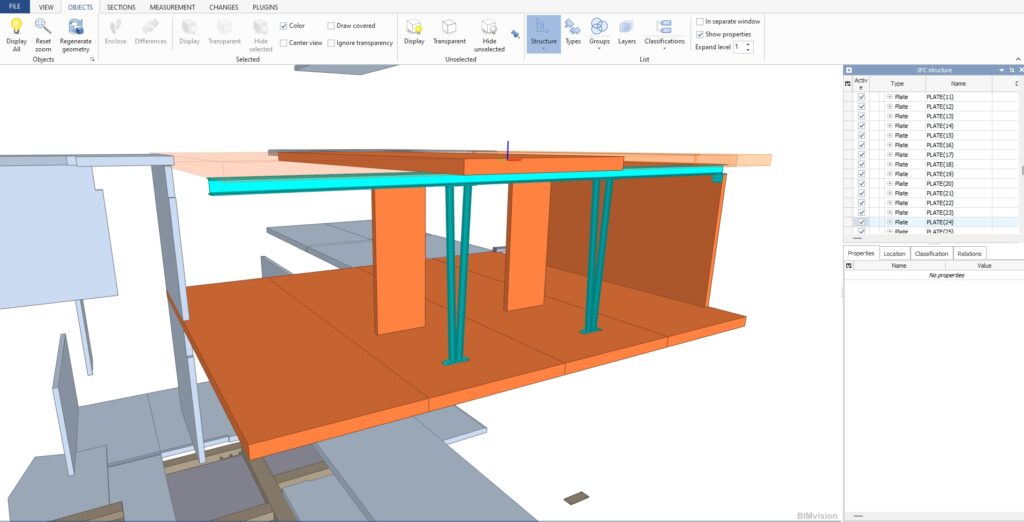

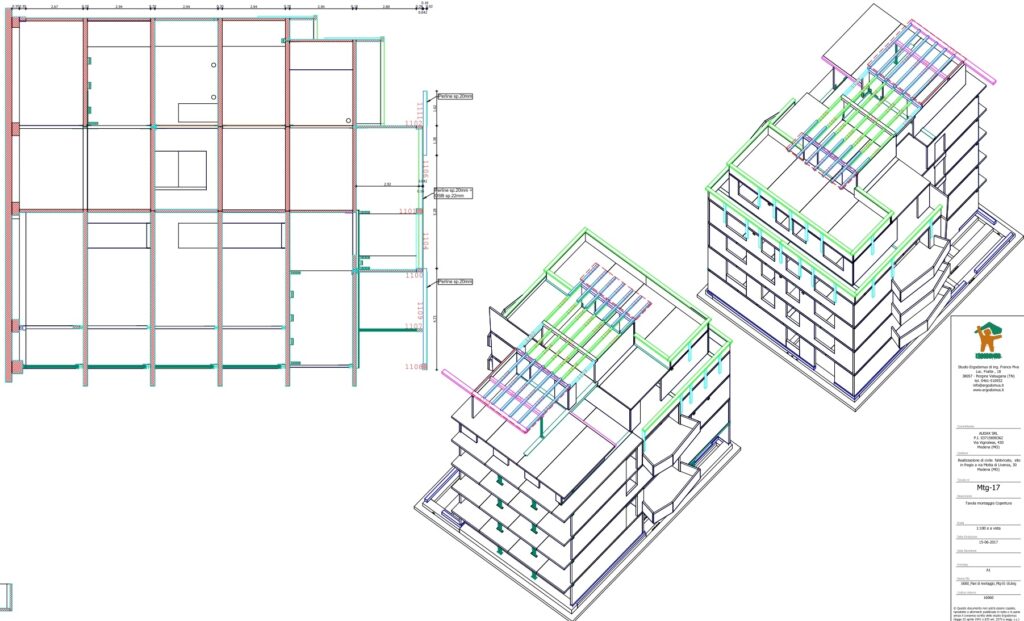

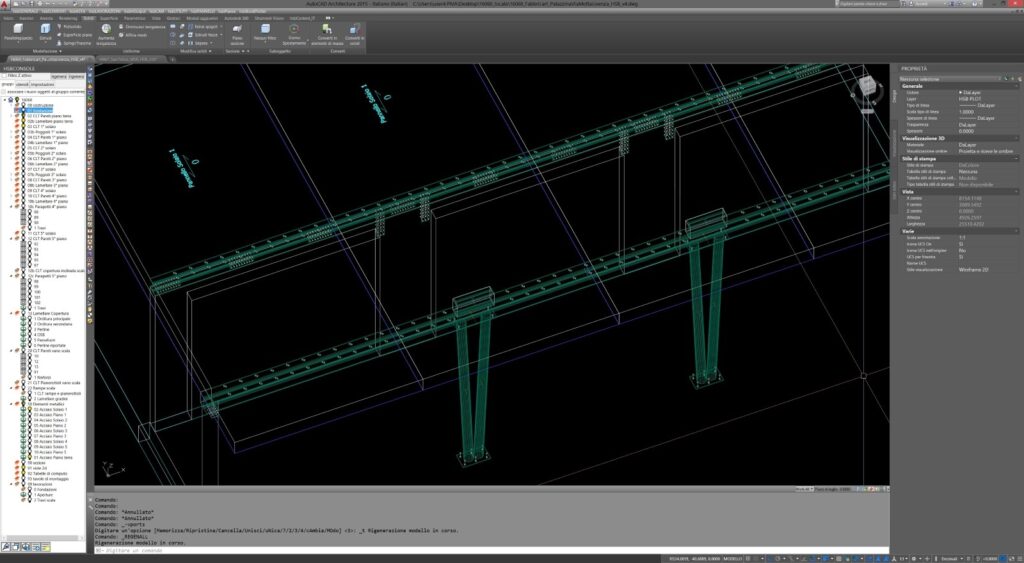

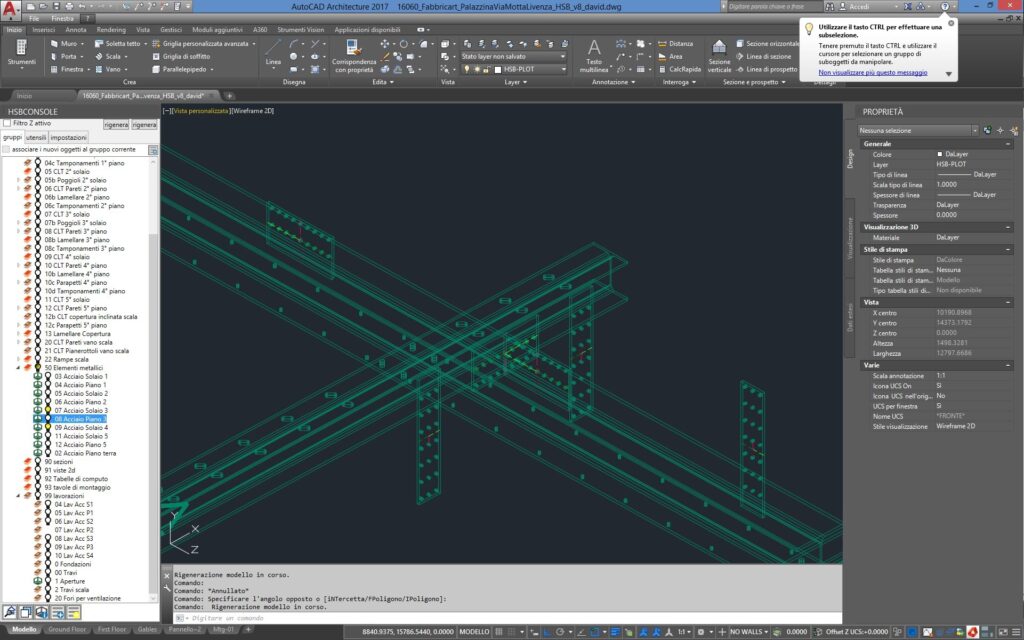

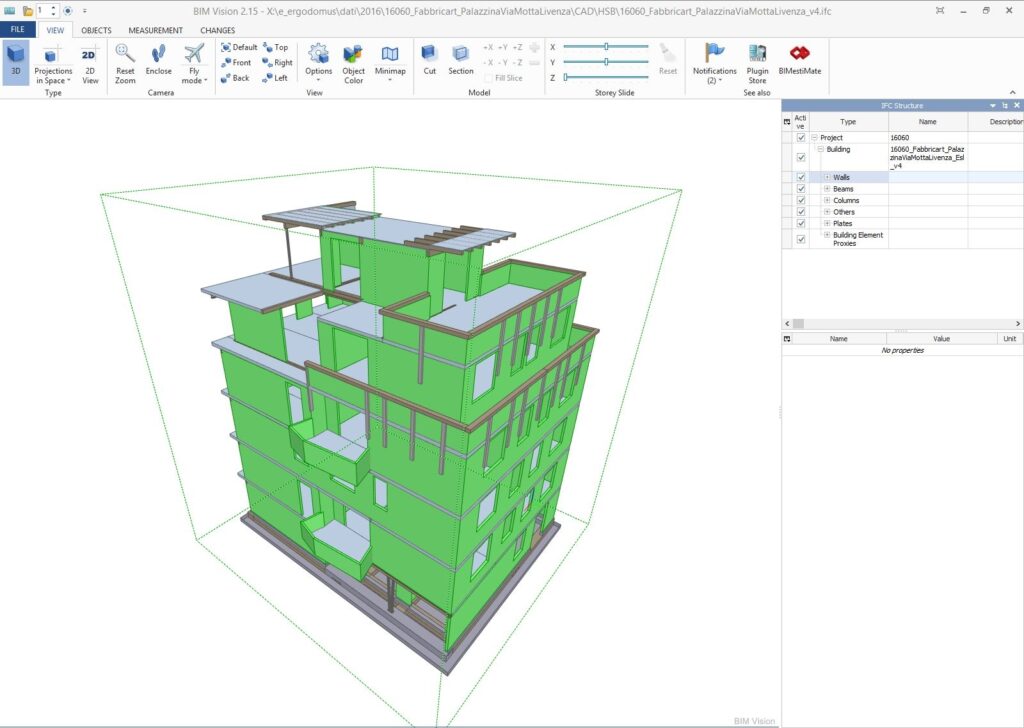

From day one, Ergodomus Timber Engineering was integral to the project’s success. Collaborating closely with the architects, we embraced a holistic design approach, working side-by-side to seamlessly integrate structural and aesthetic elements. As pioneers in the use of Building Information Modeling (BIM), we facilitated efficient information sharing through .ifc files, allowing all stakeholders to access and contribute to the evolving design in real-time.

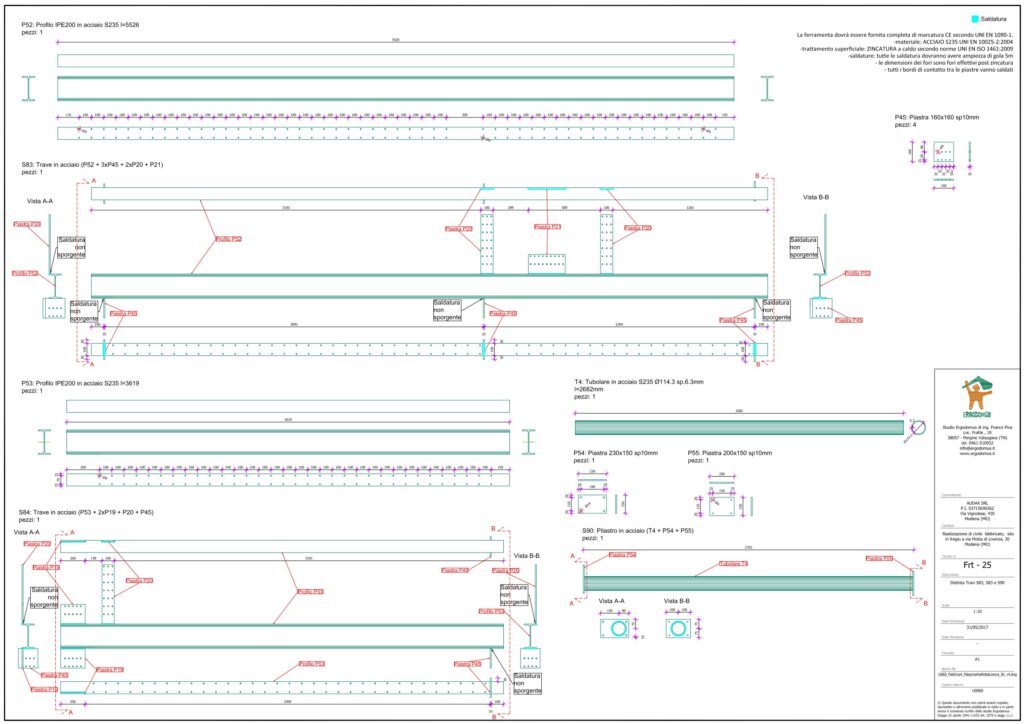

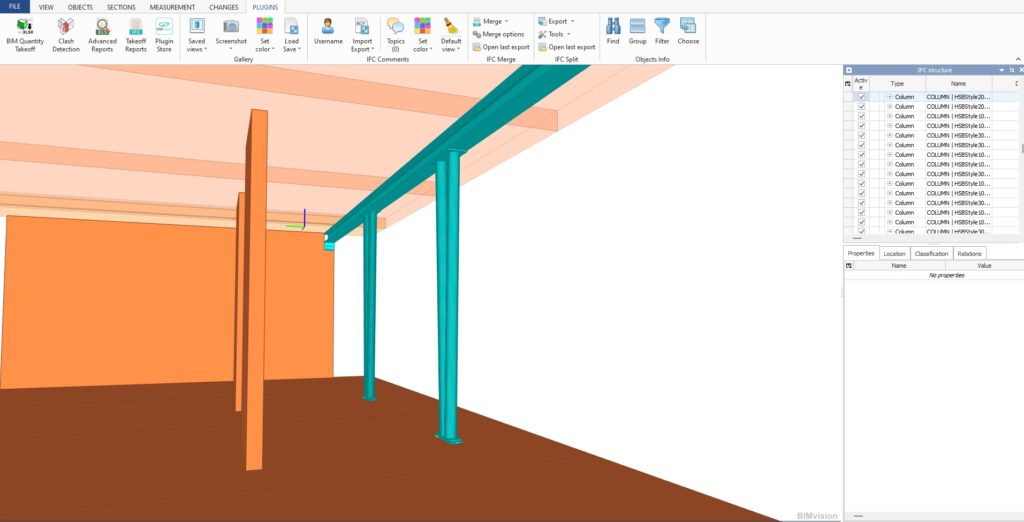

Our scope of work extended beyond structural analysis to include production drawings up to LOD 400 (Level of Development 400). This comprehensive involvement gave us the power to effectively value-engineer the project, controlling every single detail of the building. By overseeing both the engineering and detailed production aspects, we optimized materials, connections, and construction methods to achieve the best possible outcomes in terms of performance, cost, and efficiency.

Innovative Design for Seismic Resilience

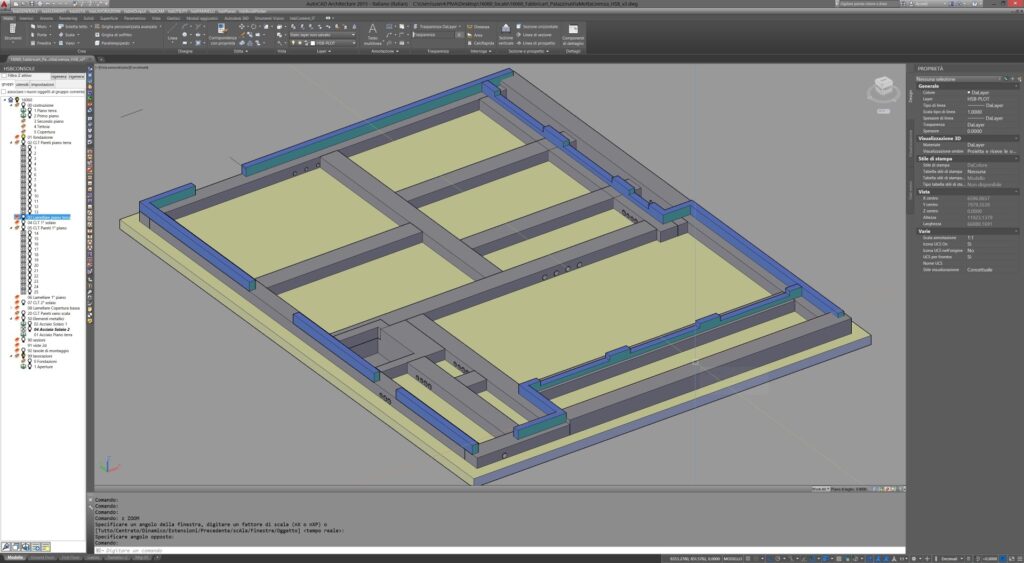

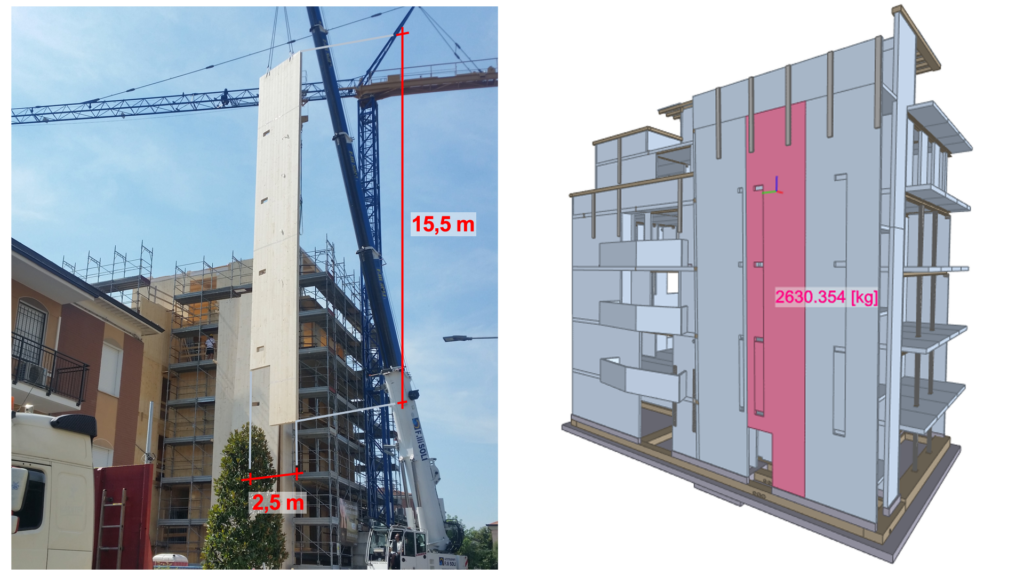

Modena is no stranger to earthquakes, having experienced a significant one in 2012. Designing a tall timber building in such an area required innovative solutions to withstand strong seismic forces. The building’s lateral system is 100% made of CLT, including the elevator and stair shafts. To achieve the necessary rigidity and resilience, we engineered these shafts using single CLT panels measuring 2.5 x 15.5 meters, extending from the ground level to the roof. Transporting and installing these massive panels required special logistics and crane operations, demonstrating our commitment to overcoming challenges with ingenuity.

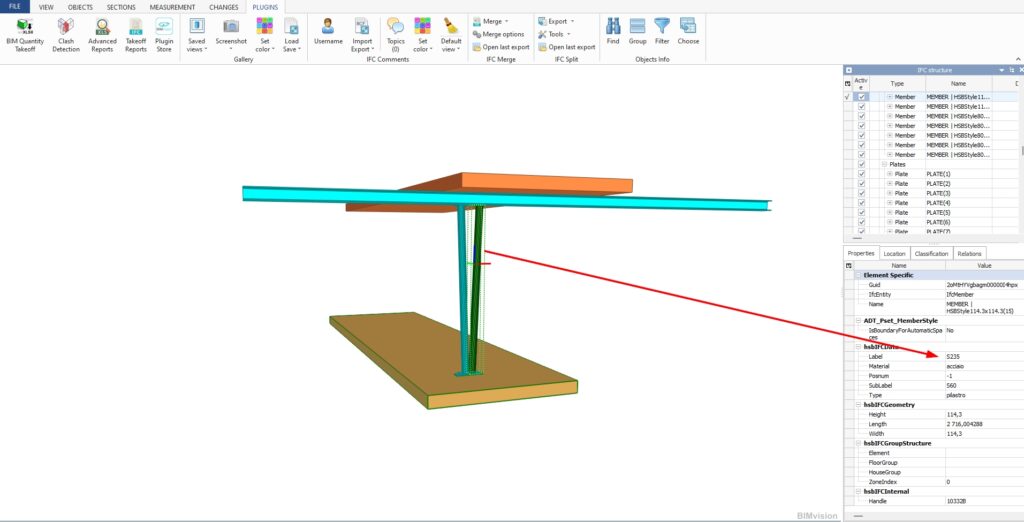

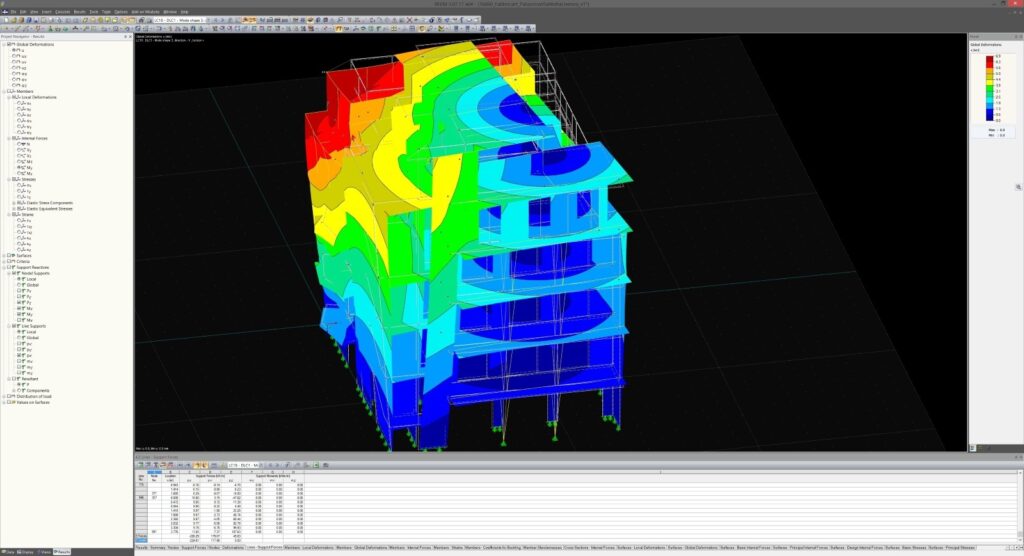

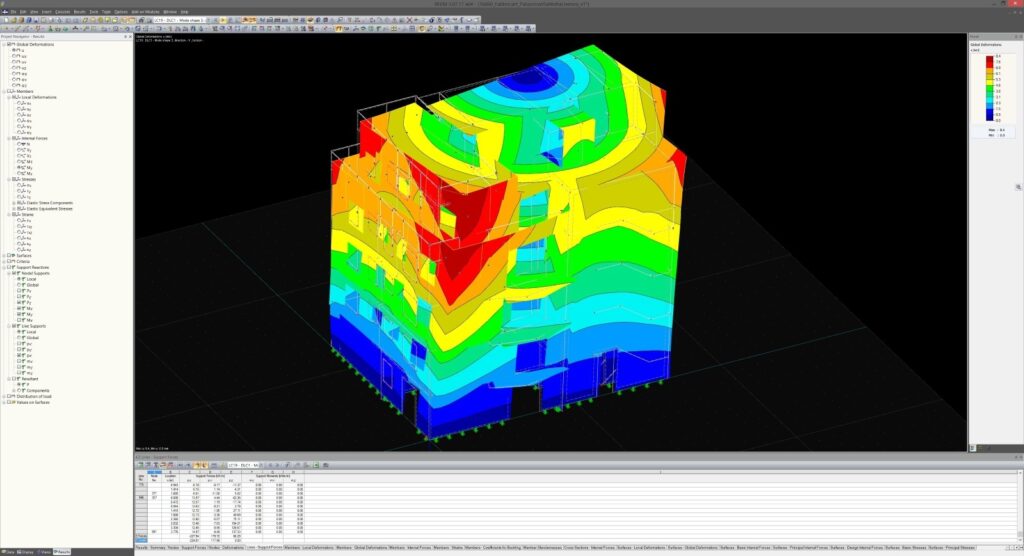

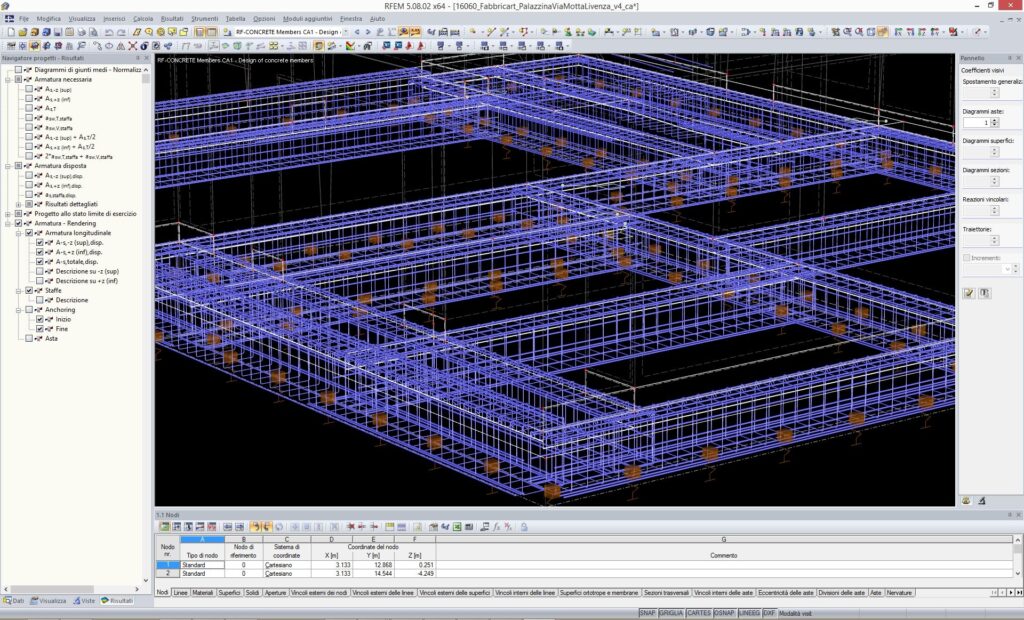

Bespoke Earthquake-Proof Connections

Understanding the critical importance of seismic safety, we developed custom “earthquake-proof” connections tailored to this project’s unique requirements. Utilizing advanced Finite Element Method (FEM) dynamic analysis, we precisely calculated the forces between the CLT walls and the reinforced concrete foundations. The analysis revealed tension forces reaching approximately 500 kN, showcasing the incredible strength and stability of the timber structure. Our designs adhered strictly to Eurocode 8, ensuring compliance with European standards for earthquake-resistant construction.

Our Scope of Work

Here, you’ll find the engineering foundation behind this 6-storey CLT building in Modena. Take a journey through the technical efforts driving our designs.

Advantages of Off-Site Construction and Detailed Planning

By embracing off-site construction methods, we optimized efficiency, quality, and safety. The prefabrication of CLT panels allowed for rapid on-site assembly, reducing construction time and minimizing disruptions. Our comprehensive shop drawings and CNC machine programming, developed up to LOD 400, ensured precision in manufacturing. This meticulous planning embodied the Design for Manufacture and Assembly (DfMA) approach, guaranteeing that every component fit perfectly.

Having detailed production drawings at LOD 400 allowed us to control every aspect of the building’s construction, from the smallest connection detail to the overall structural system. This level of control enabled us to identify opportunities for cost savings and performance enhancements, effectively value-engineering the project without compromising on quality or safety.

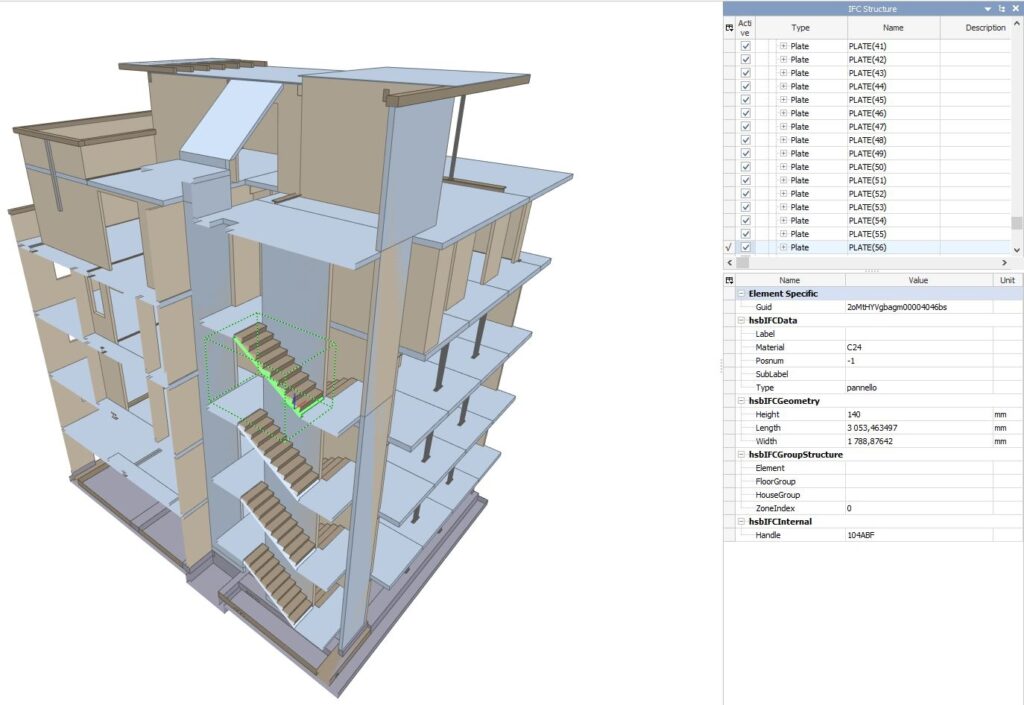

As depicted in the image above, the building’s stairs are entirely made of timber. While constructing timber stairs can be challenging, there are numerous solutions to overcome these obstacles, and the benefits are substantial. To explore this topic further, we wrote a dedicated technical article (you can read it here) that details the positive aspects and our experience working on projects featuring mass timber staircases.

Timber’s Versatility in Modern Construction

Often associated with traditional buildings, timber has emerged as a premier choice in contemporary architecture due to its speed, cost-efficiency, and excellent performance. This project underscores the versatility of mass timber, utilizing CLT panels renowned for their exceptional planar resistance. By constructing even the elevator and stair shafts entirely from CLT, we demonstrated timber’s ability to meet demanding structural requirements while providing aesthetic cohesion.

Global Recognition and Impact

The innovative nature of this building has garnered international attention. Its unique structural and geographical characteristics have made it a case study for the University of the Basque Country. Featured in the guide “Habitar en Madera”, it serves as a shining example of timber construction’s potential in creating sustainable and resilient residential accommodations.

This 6-storey CLT residential building in Modena represents a significant milestone in timber engineering, especially within a high seismic zone. Through early collaboration, pioneering use of BIM, and the development of bespoke seismic solutions—coupled with comprehensive control over the building’s details through production drawings up to LOD 400—Ergodomus Timber Engineering showcased the potential of mass timber in modern construction.

By effectively value-engineering the project, we optimized resources and enhanced performance, setting new standards for efficiency and precision in timber construction. The project’s success not only contributes to the advancement of sustainable architecture but also provides a blueprint for future developments in seismic-resilient timber buildings.

Gallery