Innovative Façade Design and Engineering

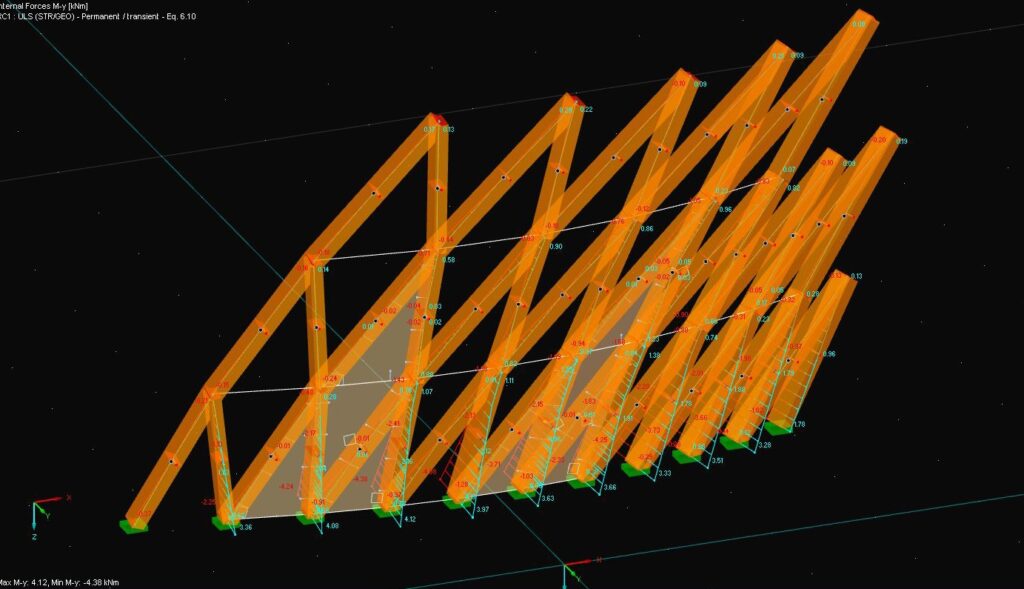

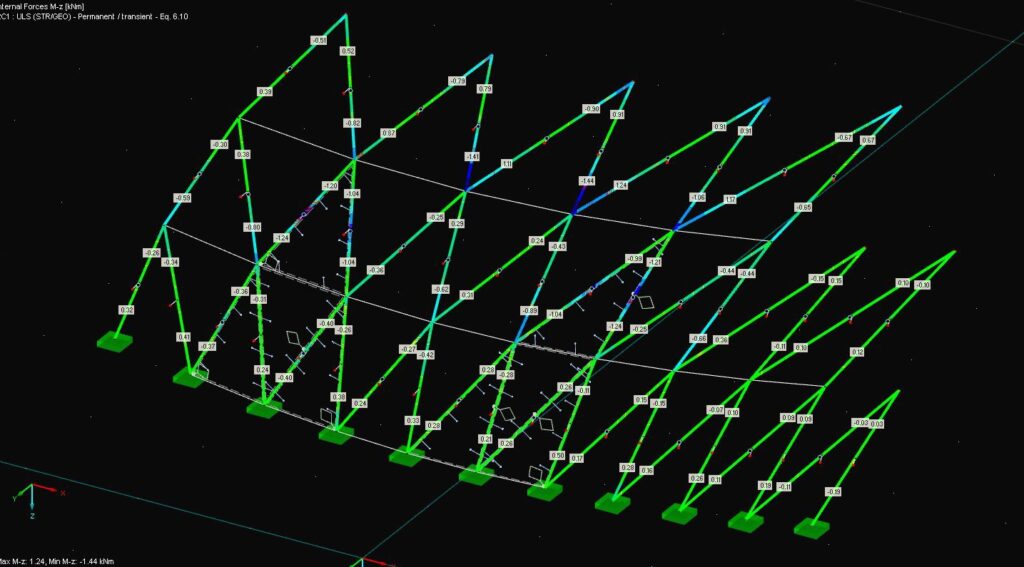

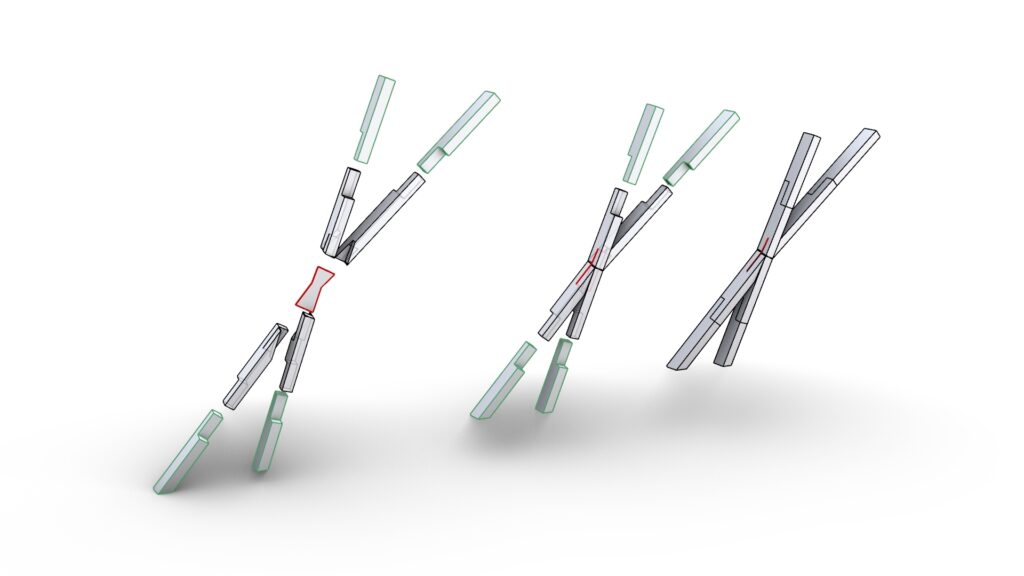

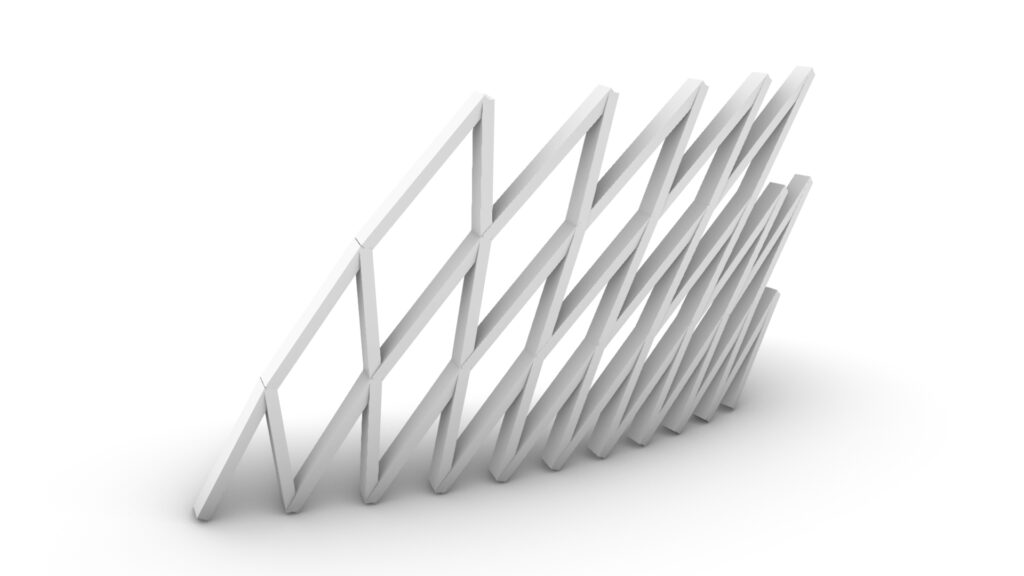

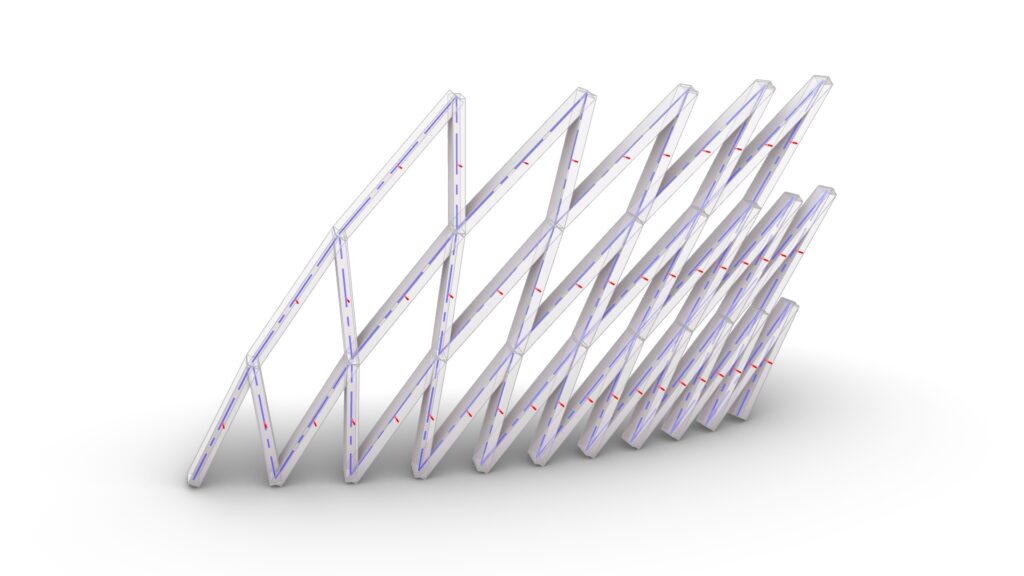

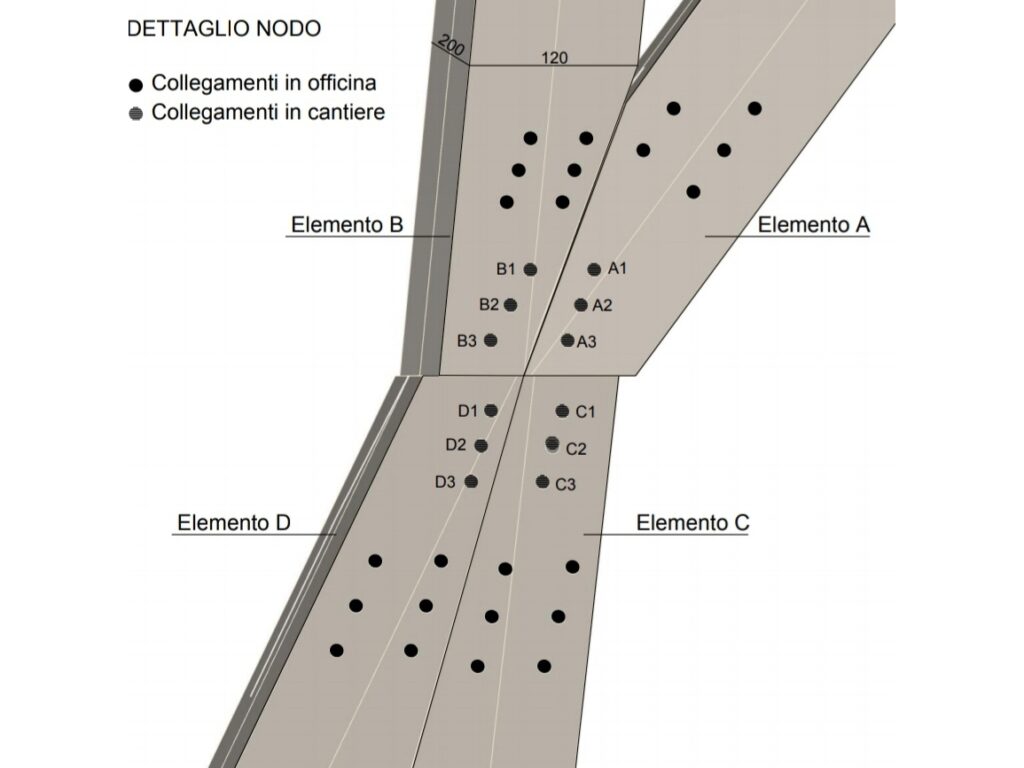

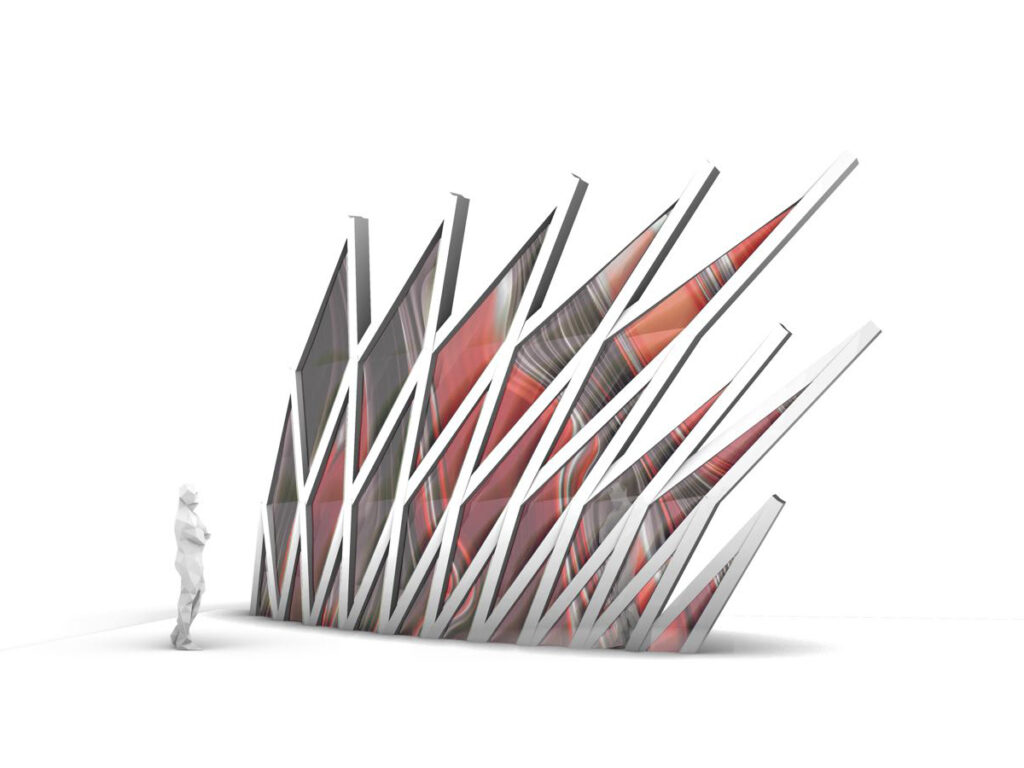

This double-curved self-supporting façade prototype, discretized into linear wooden beams, is the result of an ambitious R&D project by INDEXLAB, with engineering support provided by Ergodomus. The project focused on developing specialized joints with flat connecting plates and conducting advanced FEM analysis to ensure structural integrity and performance.

Our Scope of Work

Here, you’ll find the engineering foundation behind this Double Curvature Façade. Take a journey through the technical efforts driving our designs.

Challenges of Algorithmic Design

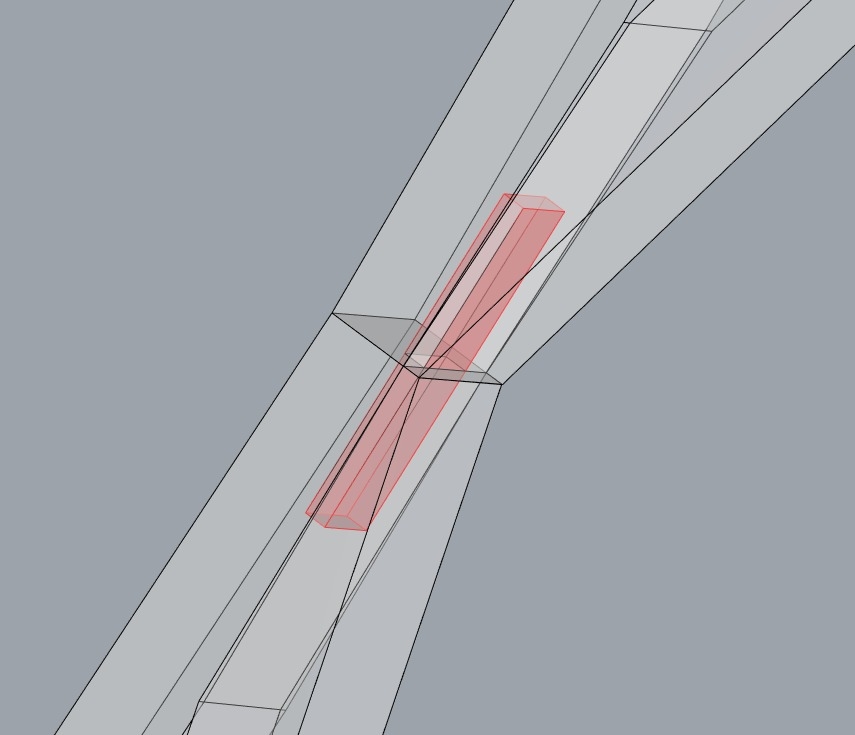

Using algorithmic modeling, the base surface of the façade was generated and then discretized into linear elements. The challenge arose from the nature of double-curved surfaces, where each beam and its connections are inherently unique. Managing the design, fabrication, and assembly of these bespoke elements with traditional methods would have been excessively complex and time-consuming, posing significant technical and economic challenges.

Integration of Computational and Robotic Methods

The innovation of this prototype lies in the seamless integration of computational logic with digital and robotic manufacturing methods. An algorithm developed by INDEXLAB automatically generated the joints and connections between beams, enabling precise extraction of geometric data for each element. This data was used to produce CNC files for manufacturing, demonstrating how cutting-edge parametric design and robotic fabrication can streamline even the most intricate construction processes. This project serves as a benchmark for advancing timber engineering and digital construction technologies.