The Timber Façade of the Alps

In the heart of the Italian Alps, Ergodomus Timber Engineering undertook the ambitious task of engineering the timber façade for the new headquarters of Durst, designed by the renowned monovolume architects. This project stands as an ode to innovation and sustainability, showcasing the harmonious blend of materials in a hybrid construction masterpiece.

The Harmony of Hybrid Construction

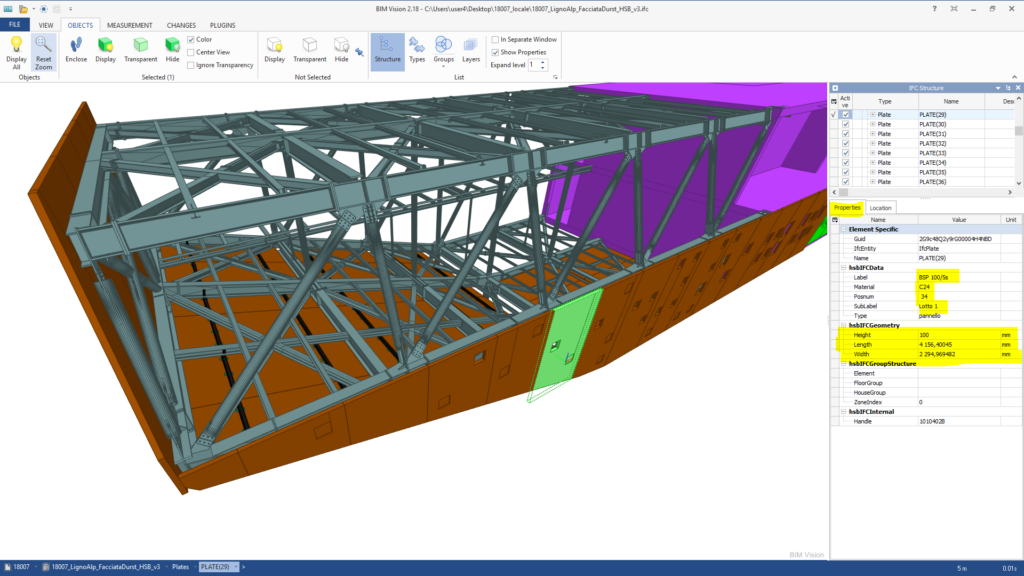

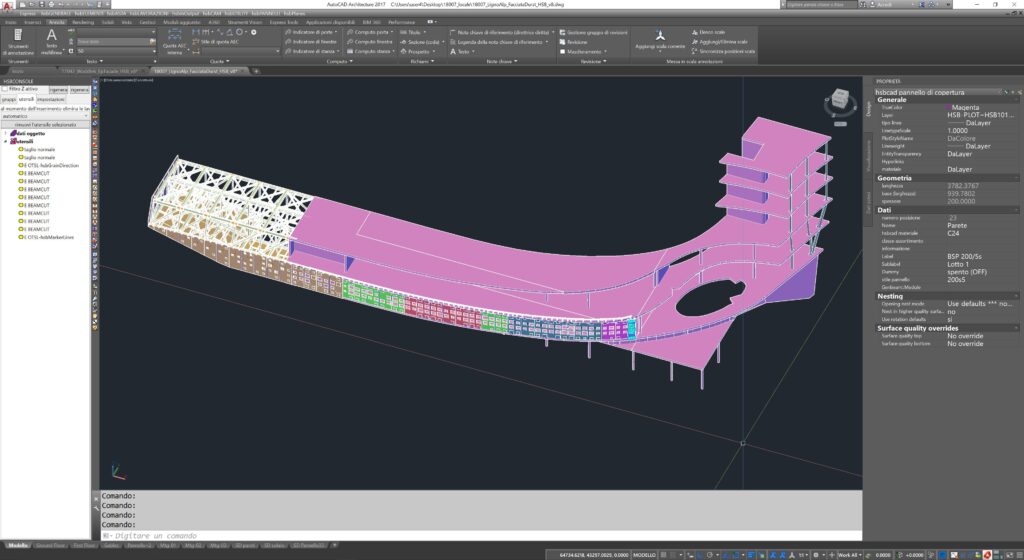

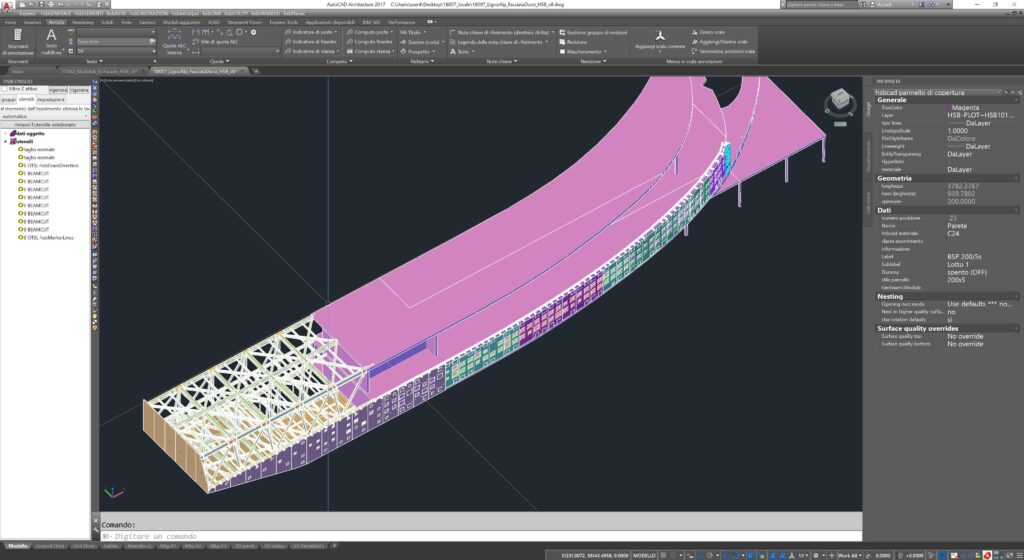

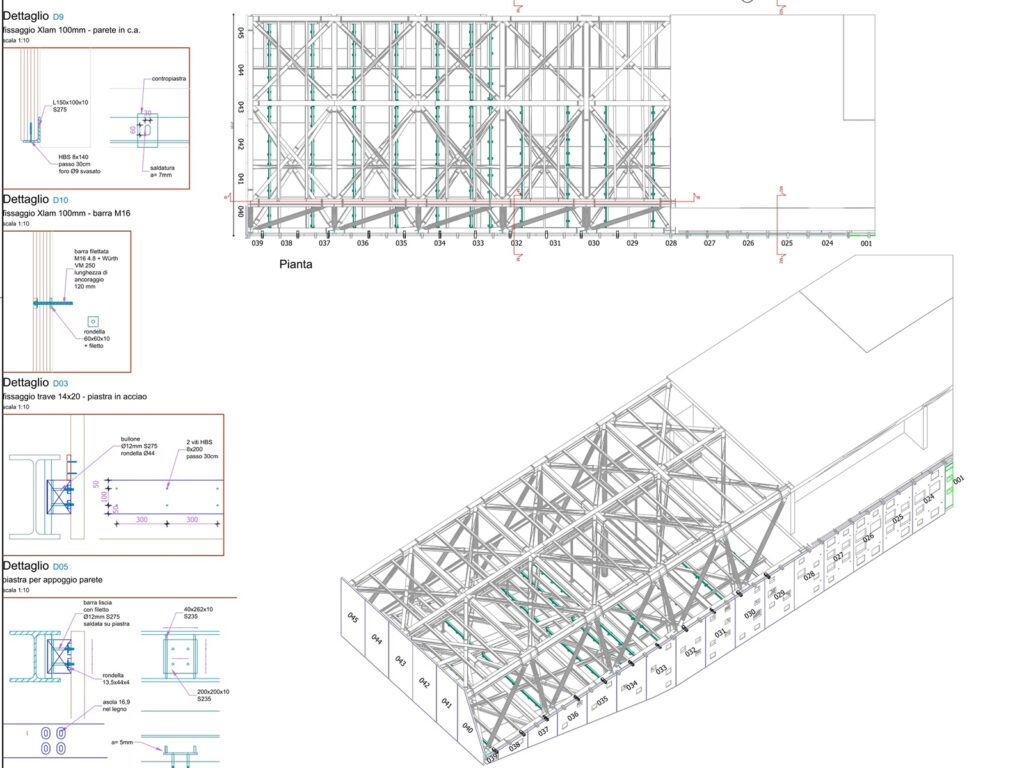

The main structure of the Durst headquarters is a combination of steel and concrete, exemplifying the future of mass timber structures through the right mix of different materials. This hybrid approach leverages the strengths of each material, achieving optimal structural integrity and aesthetic appeal. The façade is the pièce de résistance, brought to life through Cross-Laminated Timber (CLT). The decision to use CLT came after evaluating concrete and steel, which proved to be too expensive without guaranteeing a perfect result. Timber emerged as the most fitting option, offering a cost-effective solution without compromising on quality.

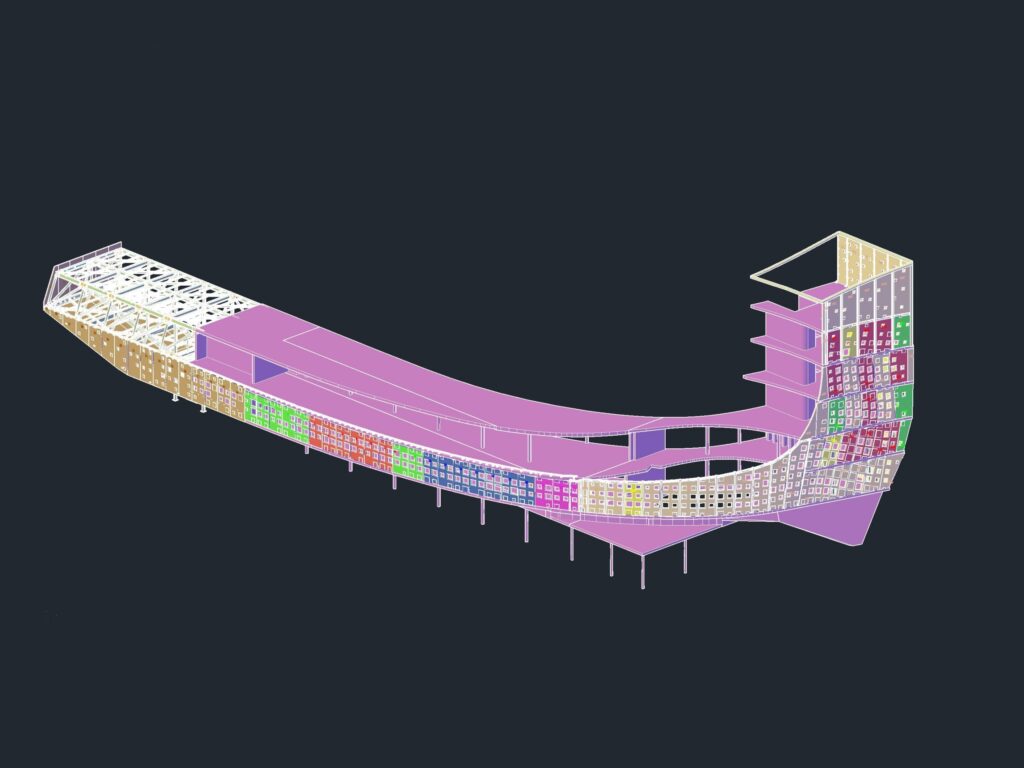

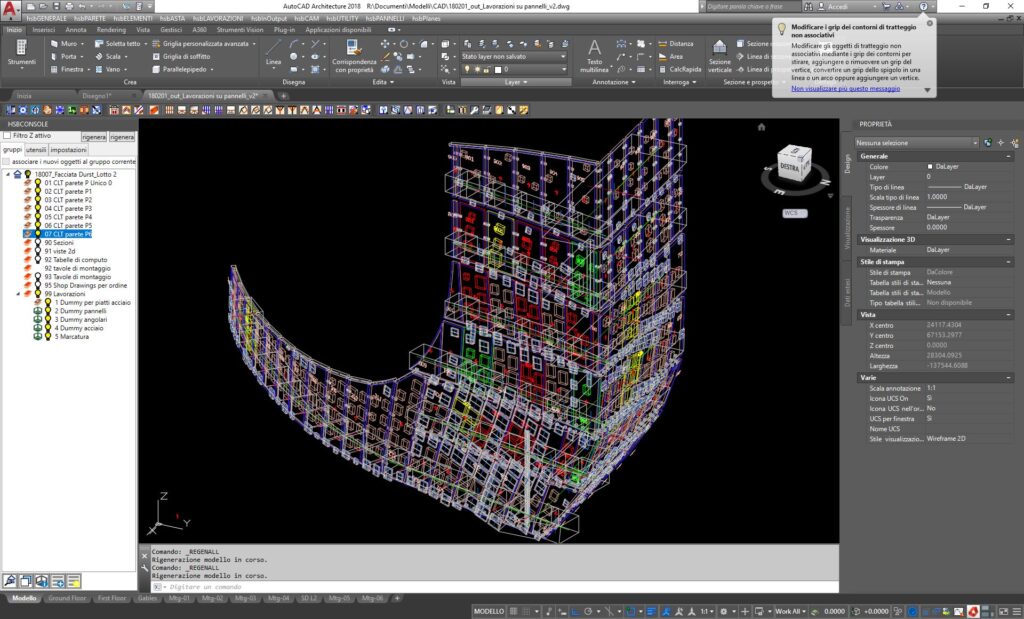

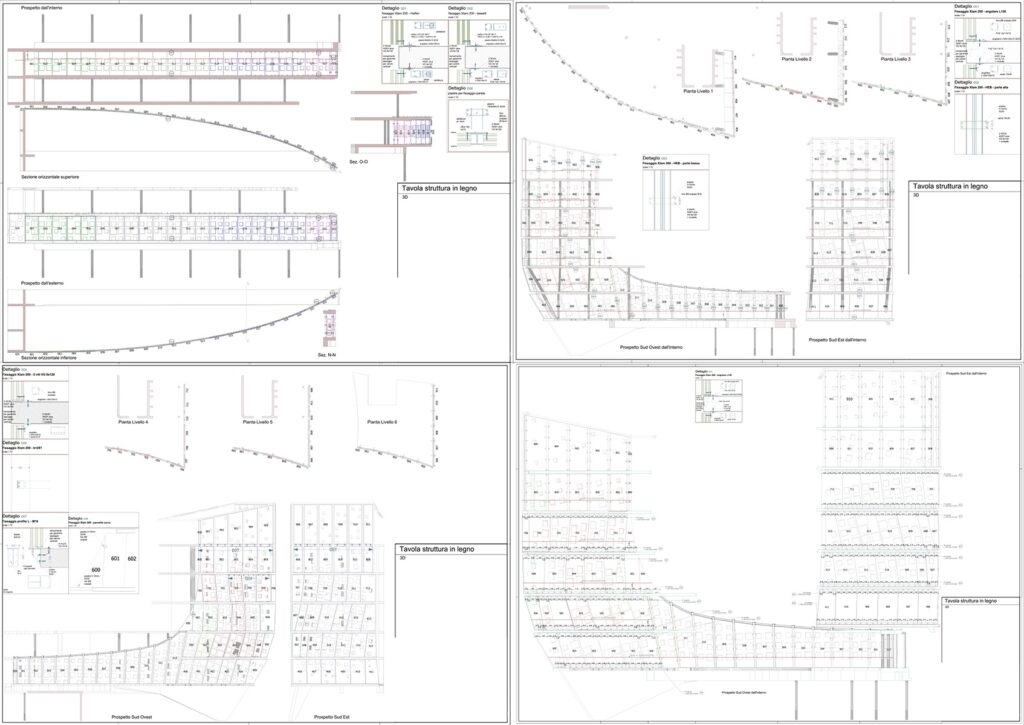

A Complex Pixelated Façade

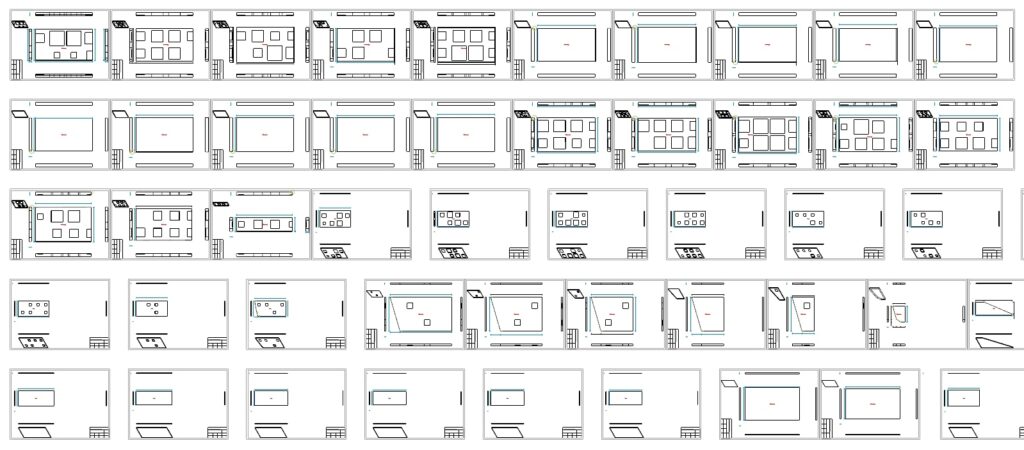

The façade’s design posed a significant challenge due to its complexity, featuring hundreds of uniquely shaped openings of varying sizes and angles. The architects envisioned a “pixel effect” on the façade, resulting in no two windows being the same or featuring a 90° angle. This demanded a level of precision and customization that could only be achieved through meticulous planning and execution.

Our Scope of Work

Here, you’ll find the engineering foundation behind this majestic façade. From Computational Fluid Analysis to advanced modeling, we provide a clear view of the technical efforts driving our designs.

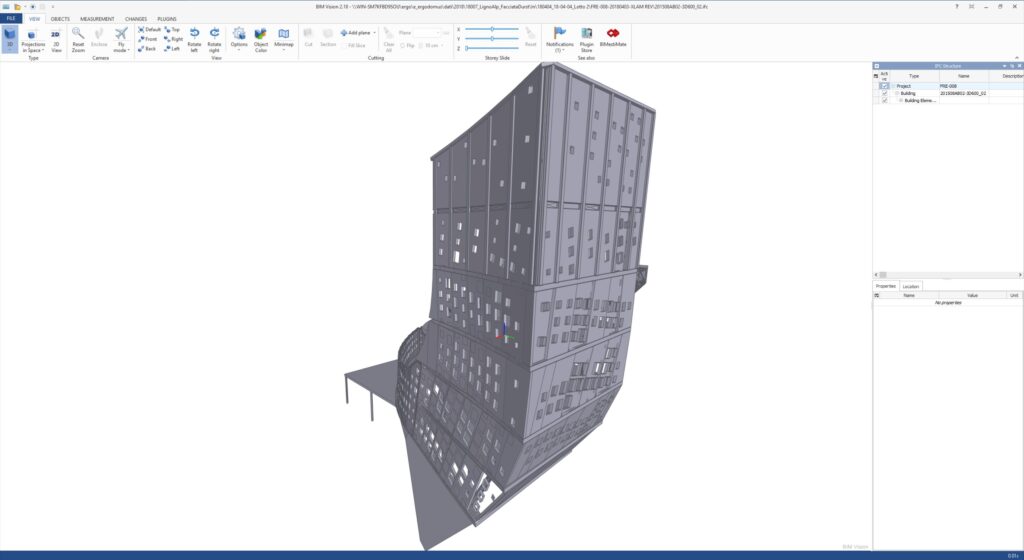

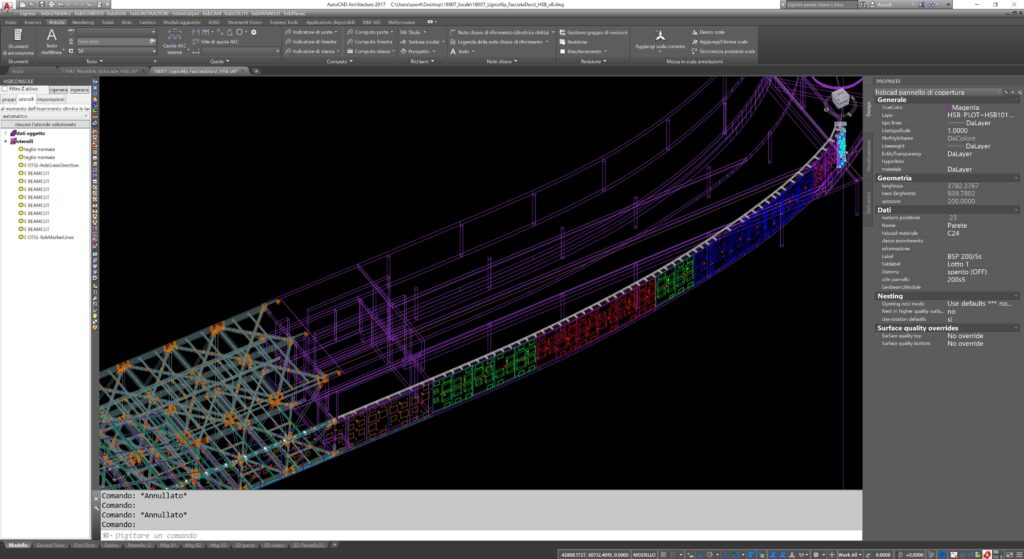

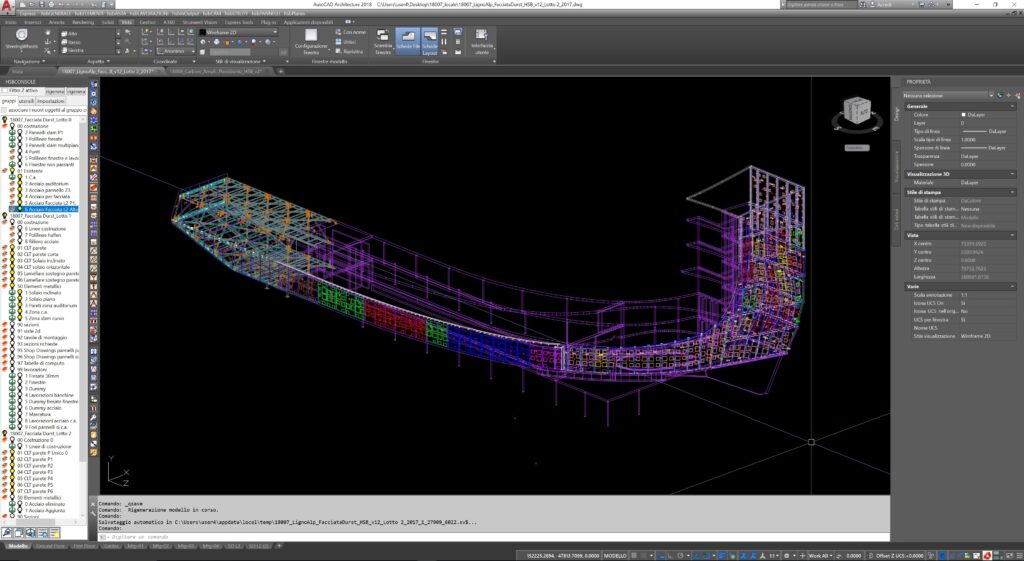

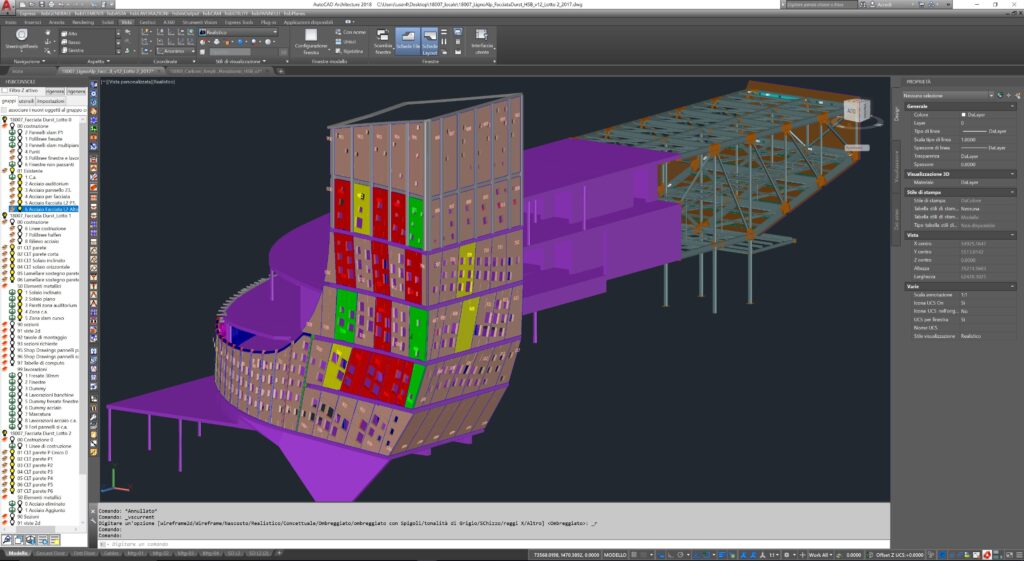

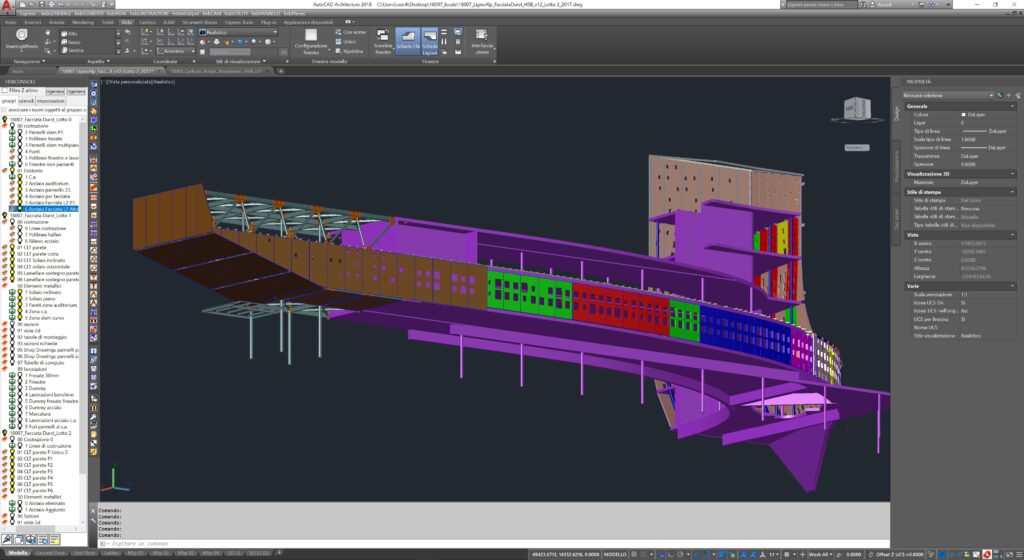

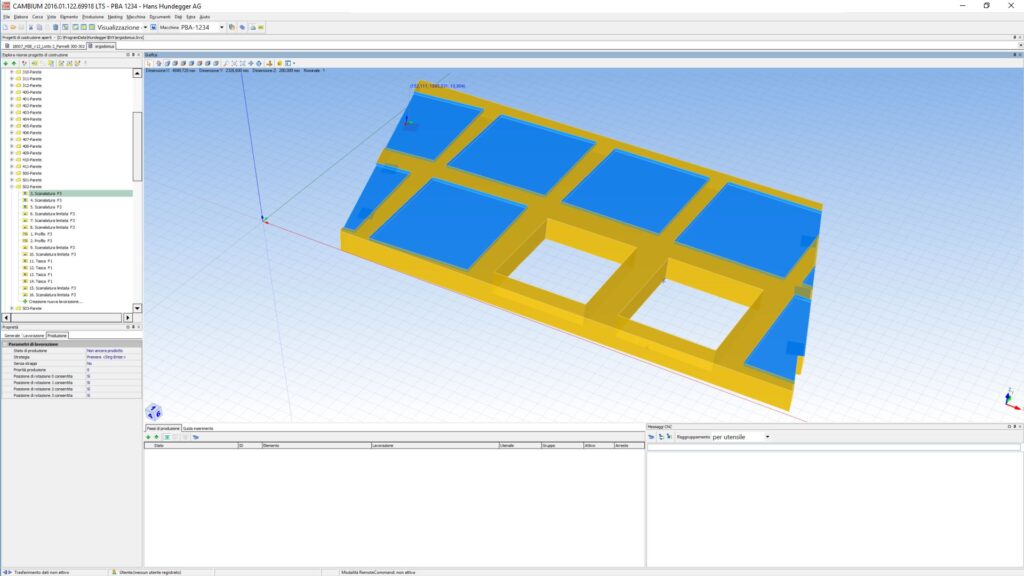

Precision through Advanced Digital Modeling

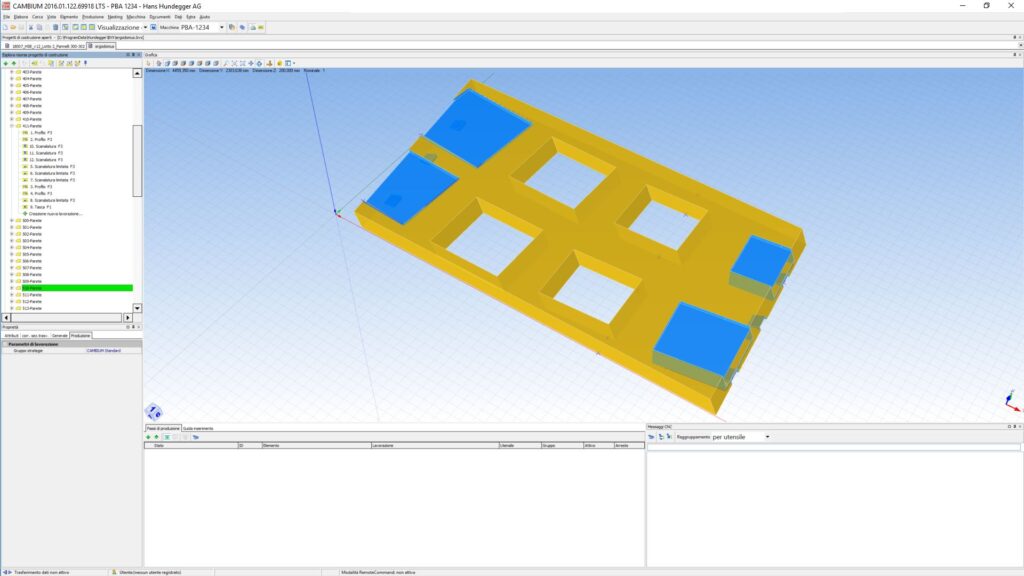

Our team at Ergodomus developed an innovative workflow to translate the architects’ Rhinoceros model into production-ready data for CNC machines. In 2018, this process was particularly challenging due to the limitations of available technology. We collaborated with HSBcad Italy, utilizing advanced software like Rhinoceros + Grasshopper, AutoCAD, and HSBcad to seamlessly import “baked” Rhino files into HSBcad. This ensured that no information was lost in translation and allowed us to generate precise production drawings—our primary scope of work. These files were then exported to CNC machines, guaranteeing that every cut was as precise as the design intended.

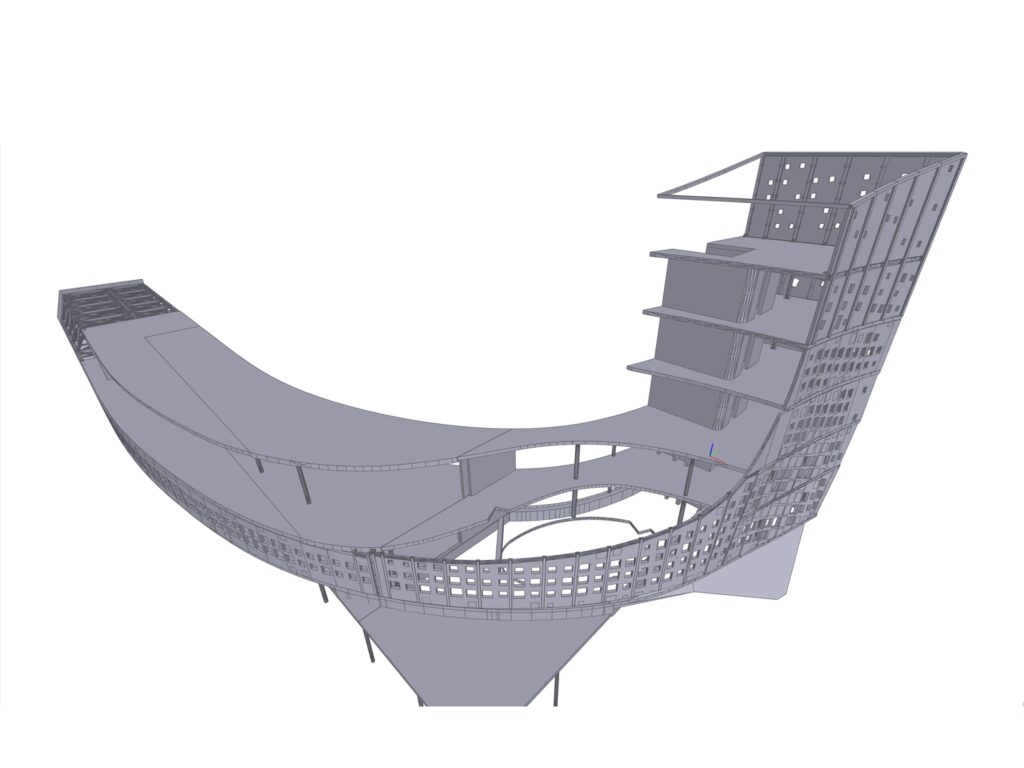

WYDIWYG, Digital Model, and DfMA

The completed façade is a prime example of our WYDIWYG (What You DRAW Is What You Get) approach. By leveraging a comprehensive digital model and embracing Design for Manufacture and Assembly (DfMA) principles, we ensured that the complex structure was accurately realized. The use of off-site construction methods allowed for quick and precise assembly on-site, which was crucial given the complexity of the façade and the hundreds of unique elements involved.

Look at the 3D Digital Model we made

We shared this Digital Model via Speckle

Sustainability and Aesthetic Excellence

While the CLT was covered on both sides, rendering the timber invisible in the final appearance, the choice of timber was essential for achieving the intricate design and maintaining dimensional stability. Moreover, this environmentally conscious decision helped lock in more than 140 tons of CO₂, reinforcing the project’s commitment to sustainability.

Conclusion

The Durst headquarters façade is an outstanding example of how human ingenuity and cutting-edge technology can come together to create something truly remarkable. Through the innovative use of mass timber, advanced digital modeling, and a collaborative effort with monovolume architects and HSBcad Italy, Ergodomus Timber Engineering has demonstrated the potential of hybrid construction in modern architecture.