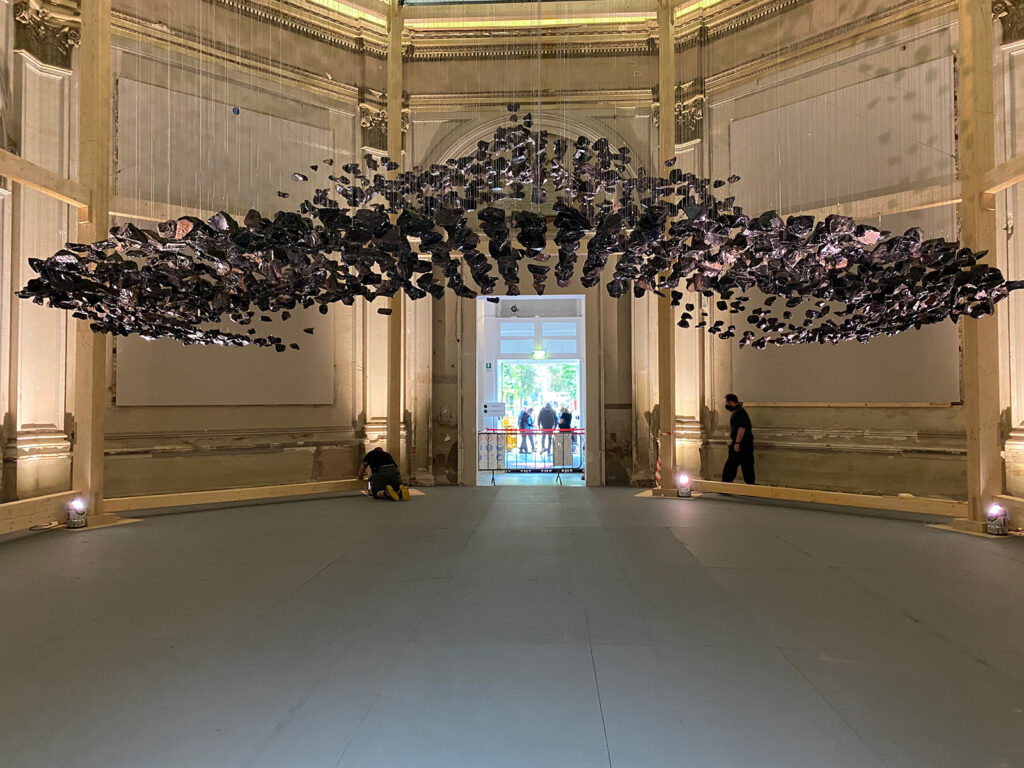

In the heart of the Biennale Gardens, a captivating structure stood as a testament to engineering excellence and creative collaboration. This is the “Obsidian Rain” pavilion, one of the main attractions of the 59th International Art Exhibition Venice Biennale, engineered by Ergodomus. Our scope of work included structural analysis, production drawings, assembly drawings, supplier coordination, and site management. We partnered closely with the “crazy” guys of Holz snc (assembly) and Bozza Legnami (wood manufacturing) to bring this vision to life.

Crafting the Cave

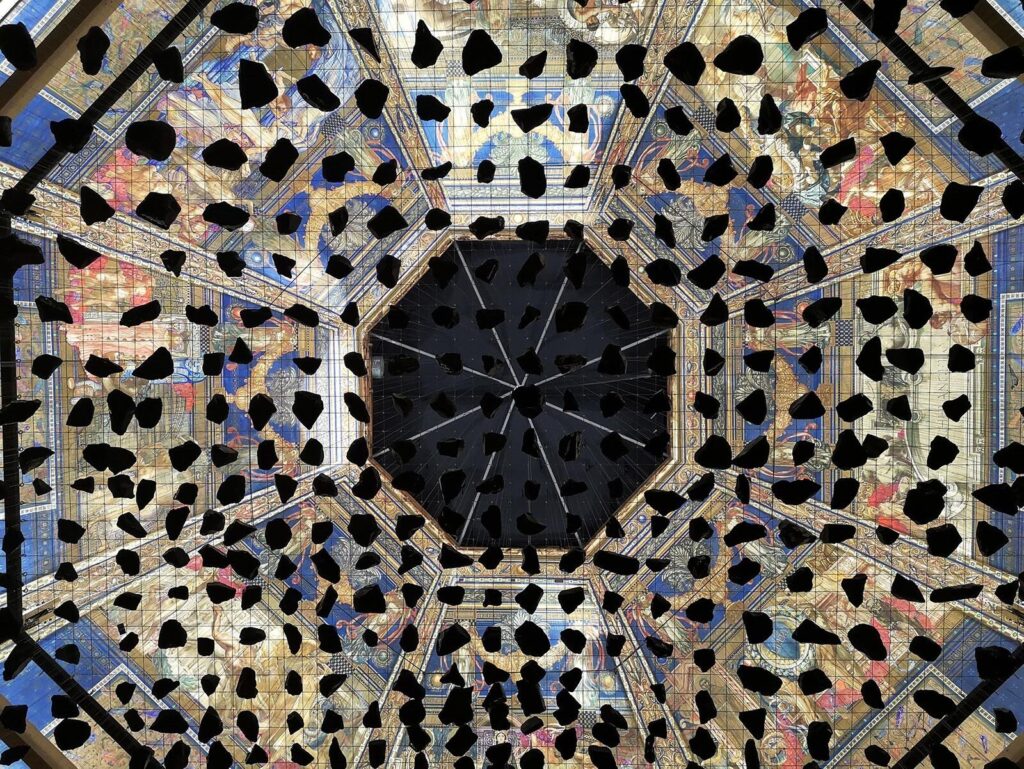

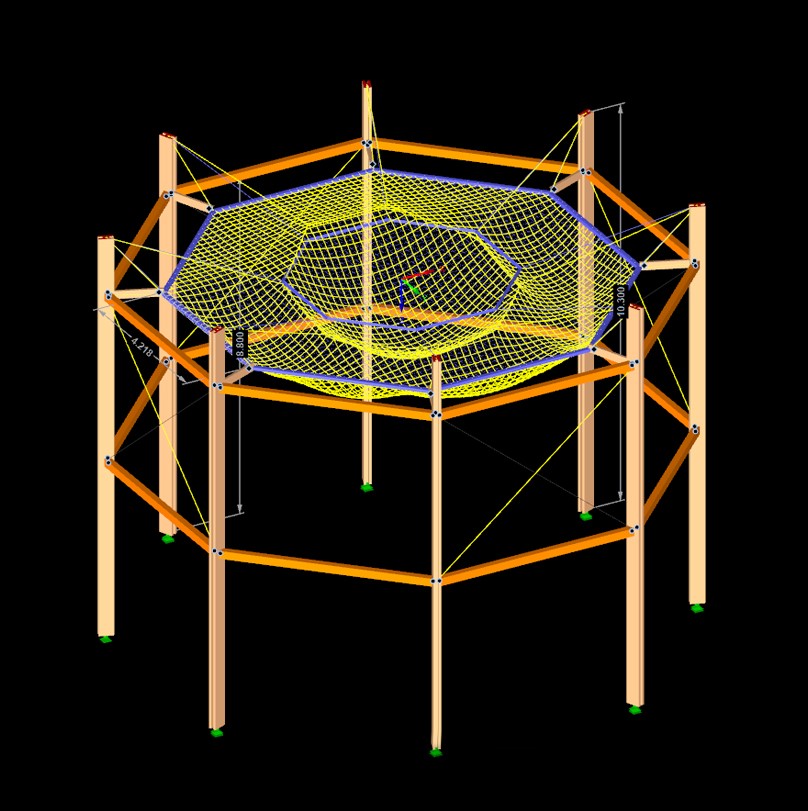

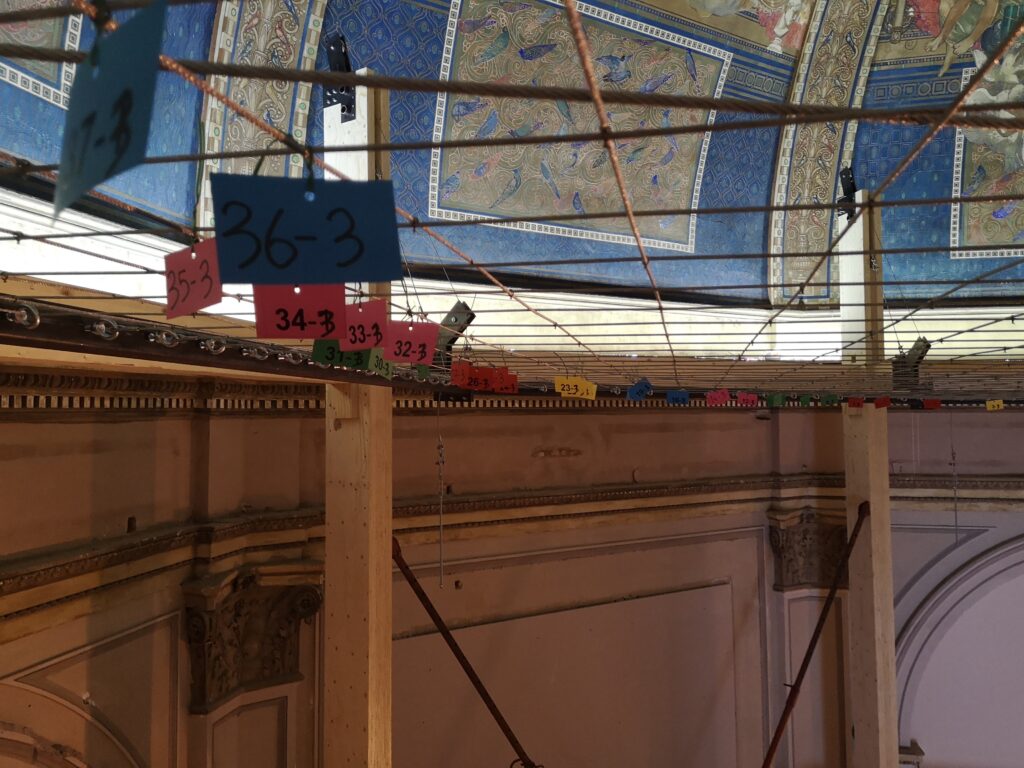

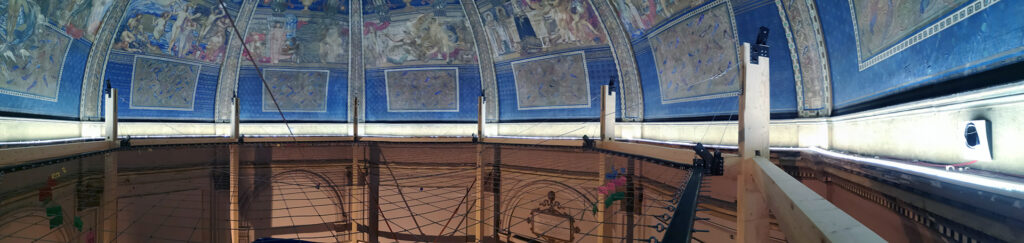

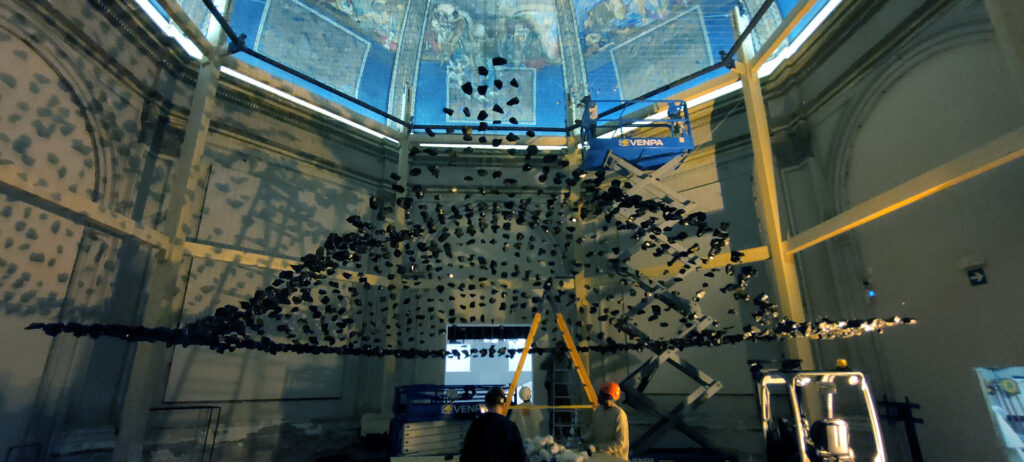

Designed by cave_bureau from Kenya, the Obsidian Rain pavilion represented a section of the Mbai cave, part of the Anthropocene Museum’s cave complex. Stepping inside, visitors found themselves beneath a ceiling adorned with 1,686 obsidian stones, each one suspended from steel ropes of varying lengths. These ropes hung from an 18×18 cm steel wire net, meticulously recreating the cave entrance, which was laser-scanned for precision. The wire net itself was suspended 8.5 meters above the ground, presenting a significant challenge due to the height. Despite the difficulty, one unforgettable aspect of the project was working just inches away from the beautiful frescos created by Galileo Chini in 1909. Being surrounded by such beauty was a once-in-a-lifetime opportunity, and we were fortunate enough to experience it.

The Engineering Challenges

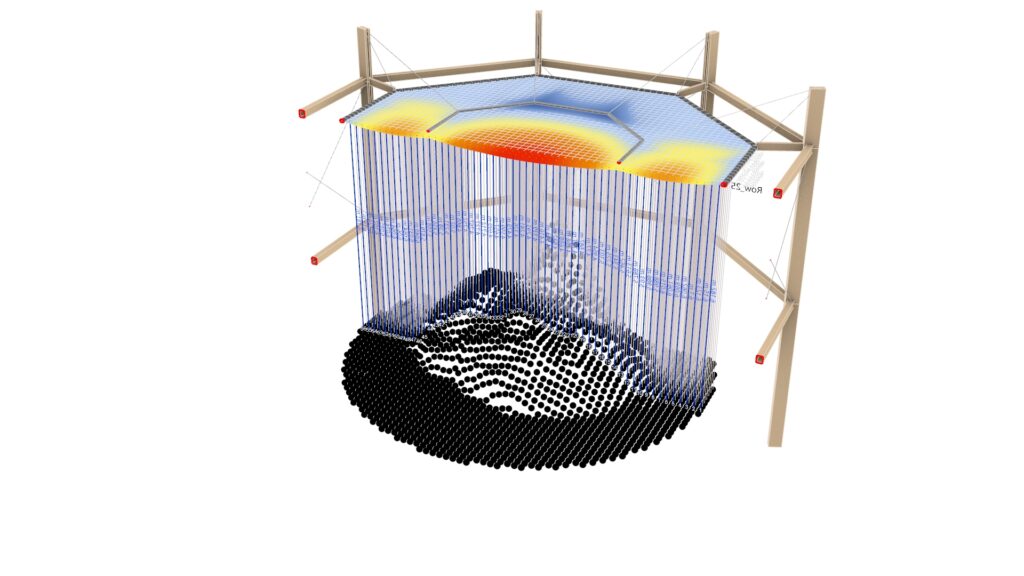

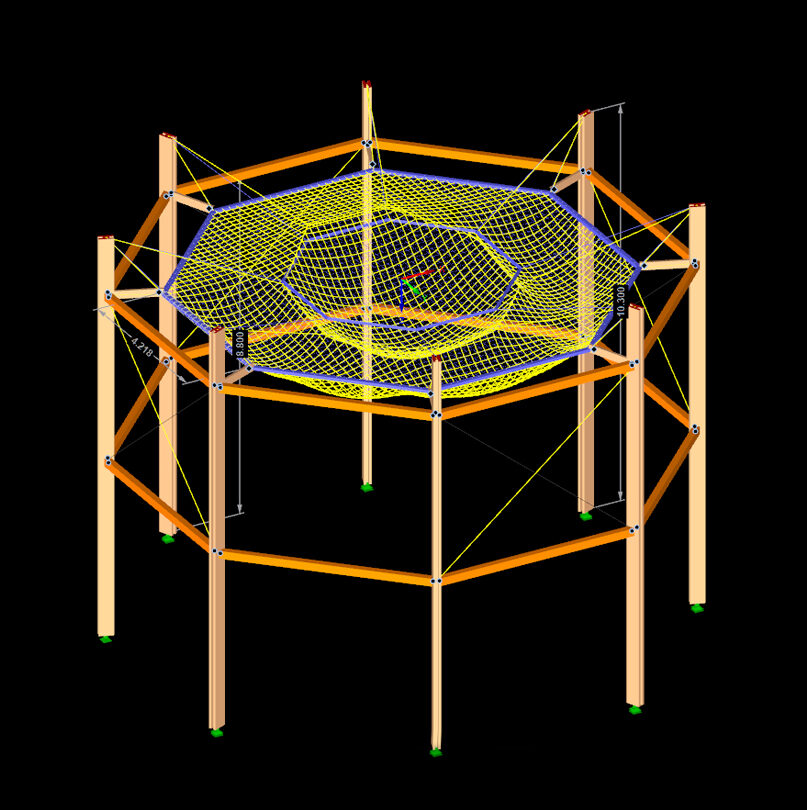

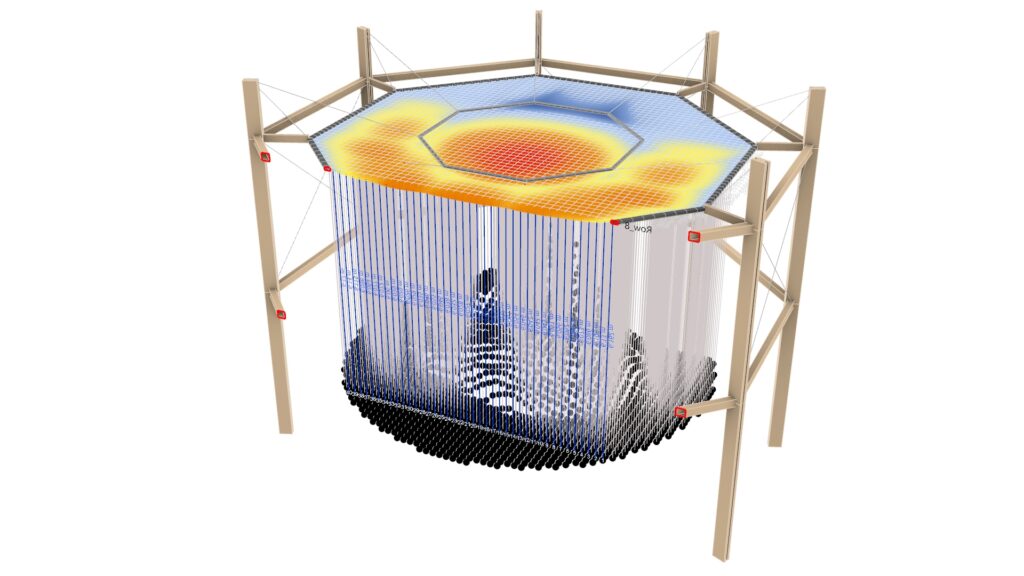

Our first challenge was to maintain the authentic shape of the cave entrance, despite the deformation caused by the weight of the obsidian stones on the steel net. This required precise calculations to predict the global deformation, allowing us to determine the exact lengths of the vertical wires. It was not an easy task. We employed highly sophisticated calculus and analysis software to achieve the desired outcome.

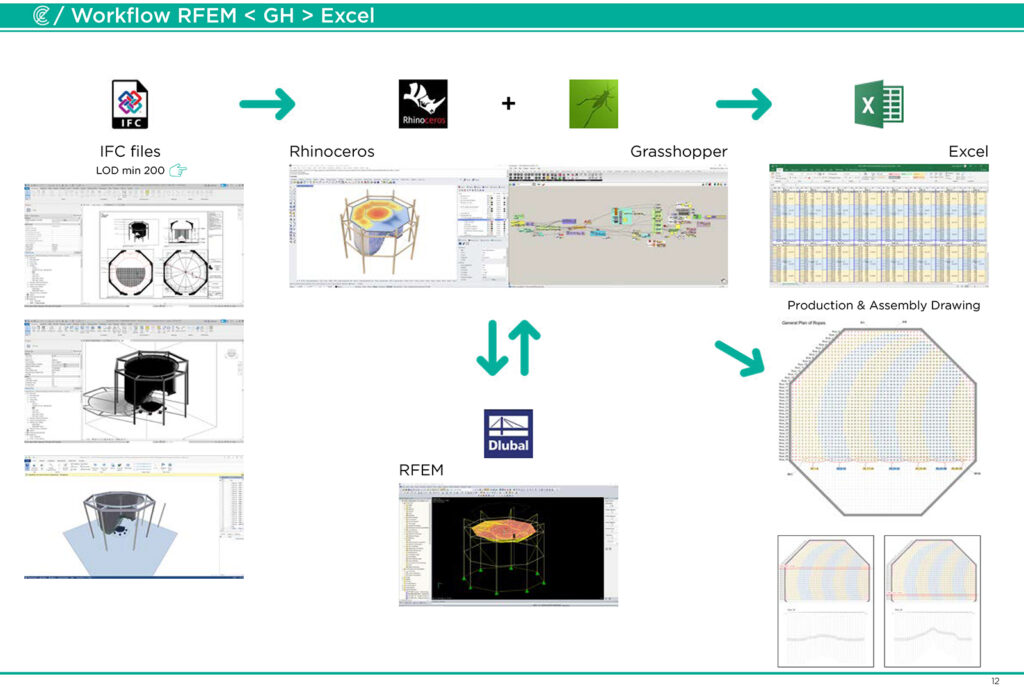

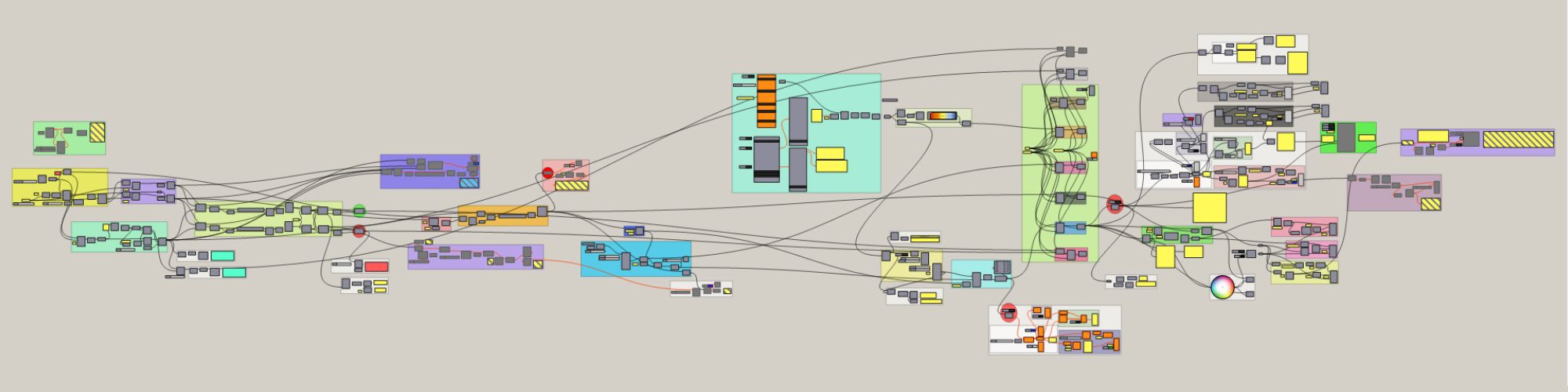

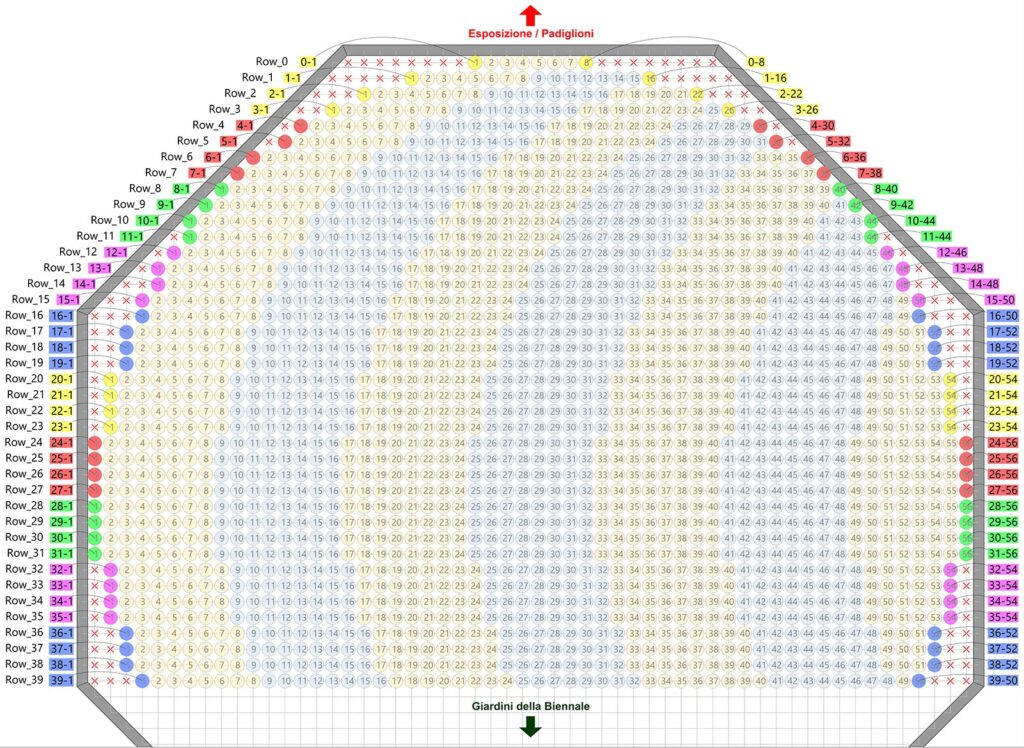

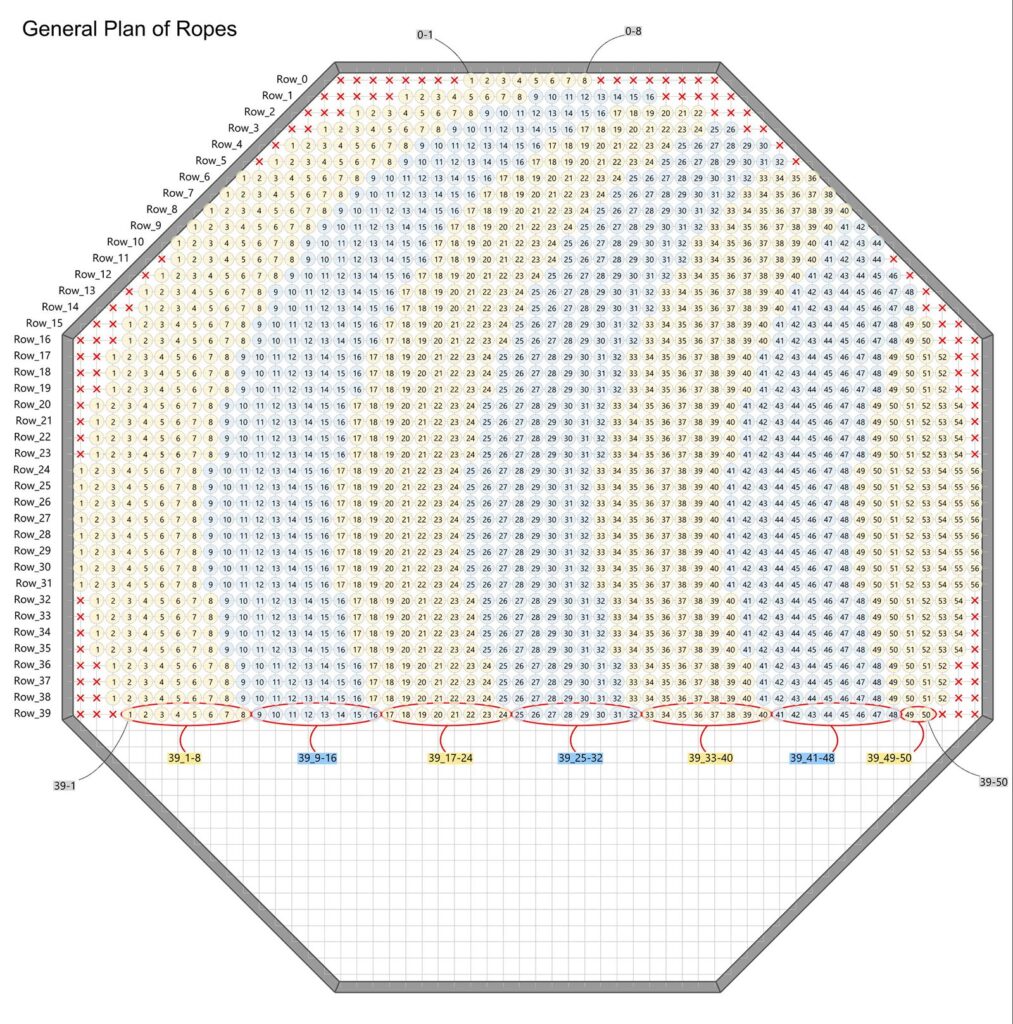

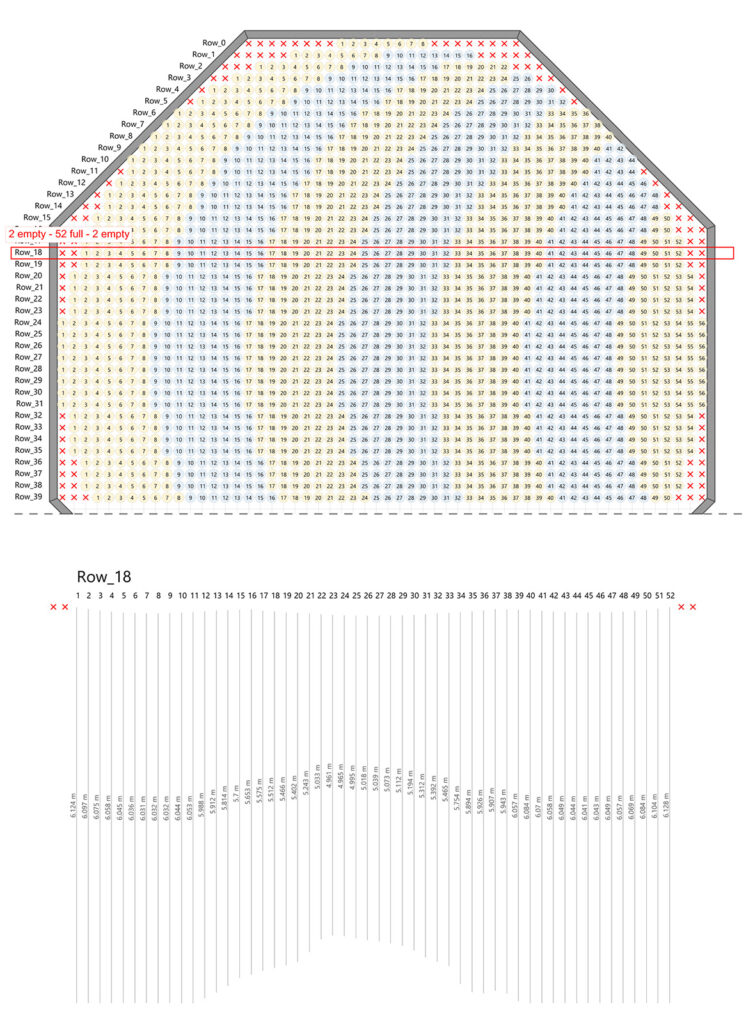

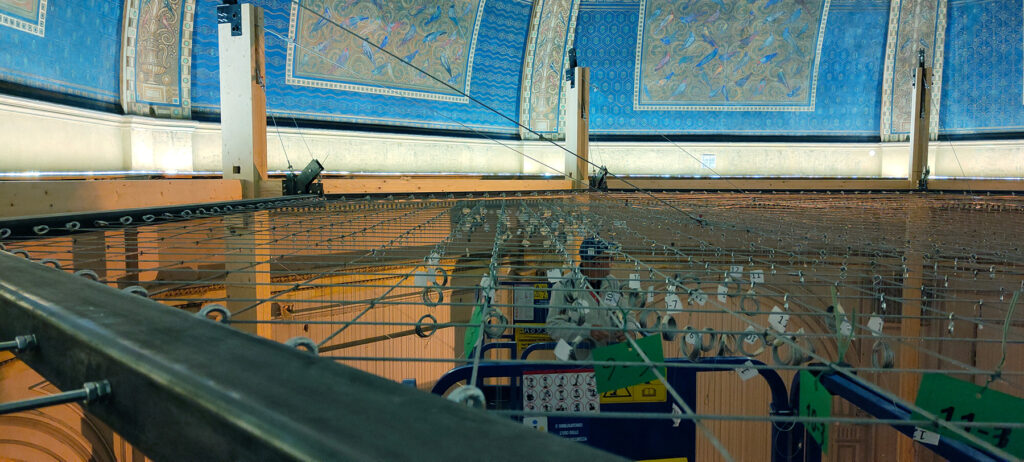

The interoperability between our structural analysis software (Dlubal RFEM) and the parametric modelling software (Rhino + Grasshopper) was crucial. This synergy enabled us to manage vast amounts of data efficiently. An algorithm updated the FEM model during various modifications, extracting the lengths of the 1686 cables, each carefully sorted by rows.

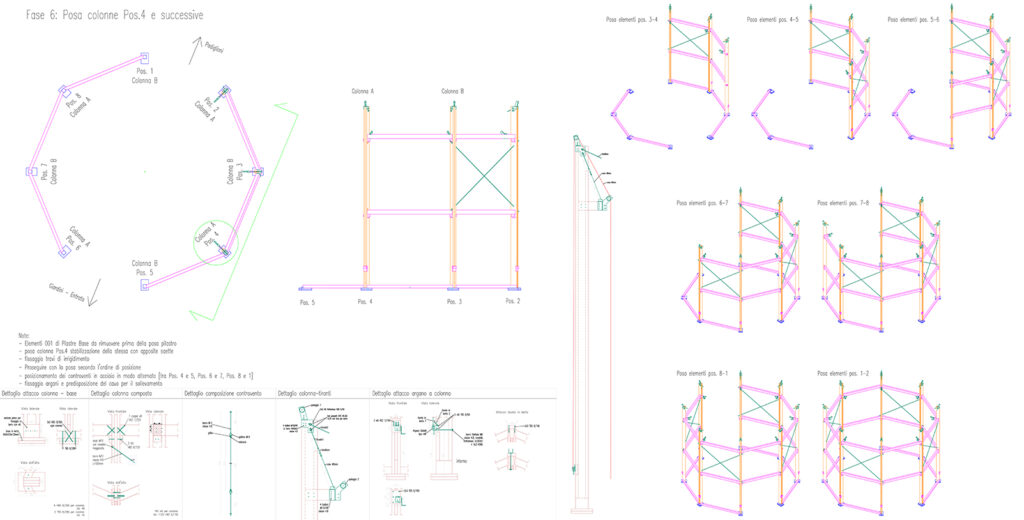

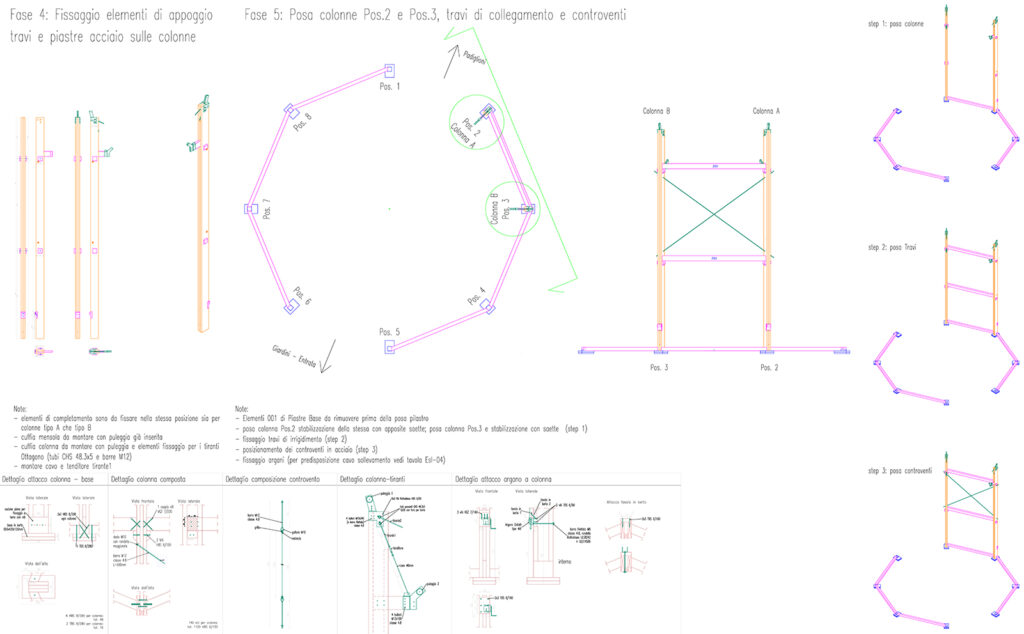

To ensure the structural elements were small, light, and stable, we opted for Kerto, designing the 10.5-meter-tall columns as hollow boxes. A steel octagon, integrated with the steel net, was bolted to these columns, providing a robust yet elegant framework.

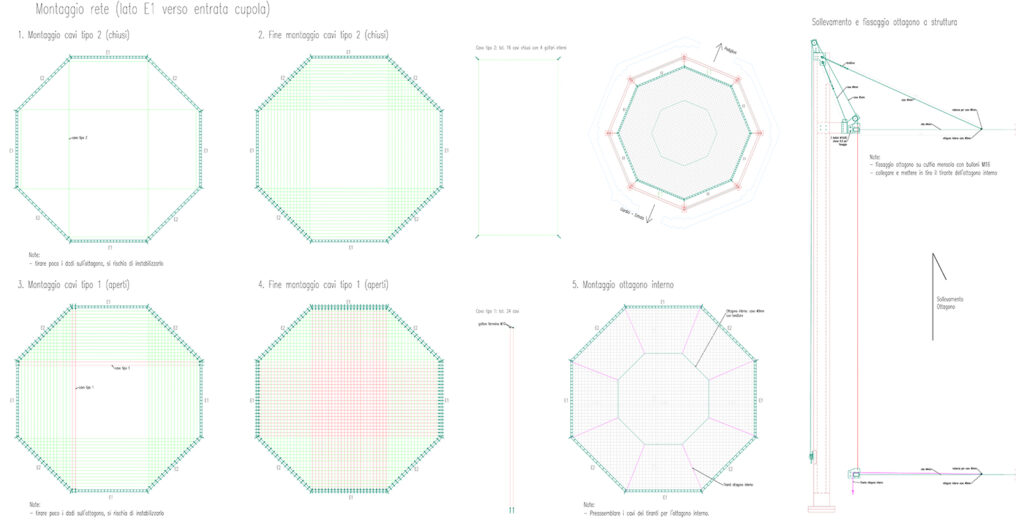

One of the biggest challenges was the 18×18 cm steel wire net. This net had to be meticulously designed and installed within a very tight timeframe. We were dealing with 1 kilometre (0.62 miles) of woven steel cables. A very complicated task. Still, we were able to complete the job in under 4 hours. By calculating and perfecting a new system to set the cables in place, we’ve been able to reduce assembly time, minimize complications and simplify the process.

Look at the 3D Digital Model we made

We shared this 3D Digital Model via Speckle

From Assembly to Disassembly: the DfMAd approach

When we embarked on this project, we knew it would only last a few months, so meticulous planning was essential from design to disassembly. Transporting materials in and out of Venice for the Biennale posed significant logistical challenges, making quick assembly and disassembly crucial. The saline air in Venice also demanded careful material selection.

Technology as a Powerful Tool

Such a complex project needed powerful tools to see the light. From start to finish, technology permeated each process ensuring seamless operativity between each stakeholder by using a 3D model. We created a 3D model to share with both the producers and the architects at cave_bureau, ensuring everyone had a clear vision of the project. The computer-generated image of the final product brought the design to life, bridging the gap between concept and reality.

But technology is to be expected when it comes to office work. The true novelty came during the construction stage, where we didn’t just rely on traditional assembly drawings.

We used an augmented reality app developed internally here at Ergodomus to expedite the assembly process and minimize errors. Installed on smartphones, our app allowed our team to virtually visualize the structural elements along with their labels, significantly enhancing accuracy and efficiency. We believe that AR and its benefits might change the construction field.

The Race Against Time

The final phase of construction was a race against the clock. We were asked at the last minute to hang all the obsidian stones. We were surprised and knew it would have been a challenge but decided to follow through with the job.

Despite these challenges, the exceptional teamwork among all involved companies, professionals, and architect Kabage Karanja (co-owner of cave-bureau studio who worked with us for the entire night) enabled us to hang the last stone at 3:00 am, just in time for another team to clean right before opening. The Biennale opened at 10 am as scheduled, showcasing the Obsidian Rain pavilion as a masterpiece of engineering and artistry.

Through meticulous planning, innovative technology, and collaborative effort, Ergodomus and our partners turned a complex vision into a stunning reality. The Obsidian Rain pavilion is a testament to what happens when engineering precision meets creative ambition, captivating visitors with its blend of natural beauty and technical prowess.

Gallery