A Landmark in Hybrid Timber Engineering

The recently completed Sages Road Depot in Australia stands as a testament to innovative timber engineering, showcasing cutting-edge design and advanced construction techniques. Commissioned by the Greater Metropolitan Cemeteries Trust, this two-story operations depot serves as the headquarters for Northern Memorial Park (NMP) operations and River Red Gum. Designed to foster a sense of community among employees, the building features offices, meeting rooms, a lunchroom, collaborative spaces, and an auditorium, efficiently accommodating all vehicles, equipment, and tools necessary for the park’s daily operations.

Collaboration with Local Experts

Ergodomus Timber Engineering worked closely with local architects SxWA and general contractor Building Engineering. This collaboration was pivotal in bringing the project to fruition, combining international expertise with local knowledge. The success of this partnership was facilitated by regular weekly meetings at 6 a.m. Rome time, demonstrating our commitment to effective communication despite time zone differences.

More information about the project can be found on their websites:

SxWA’s Project Page: Northern Memorial Park Depot

Building Engineering’s Project Page: Sages Road Depot

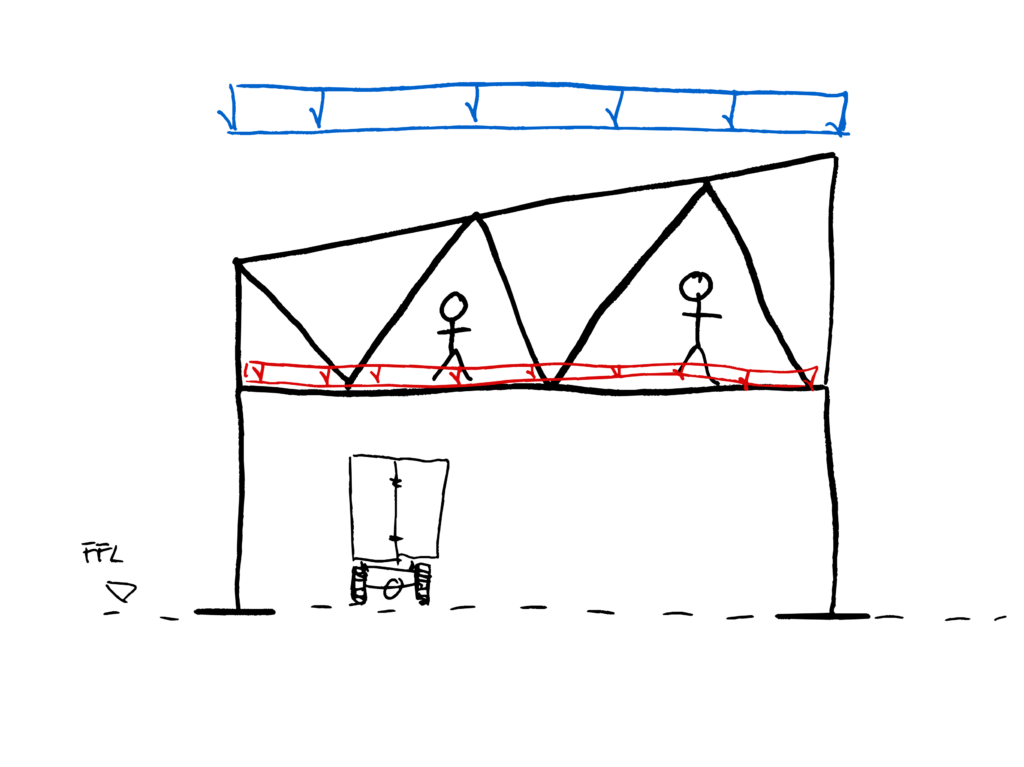

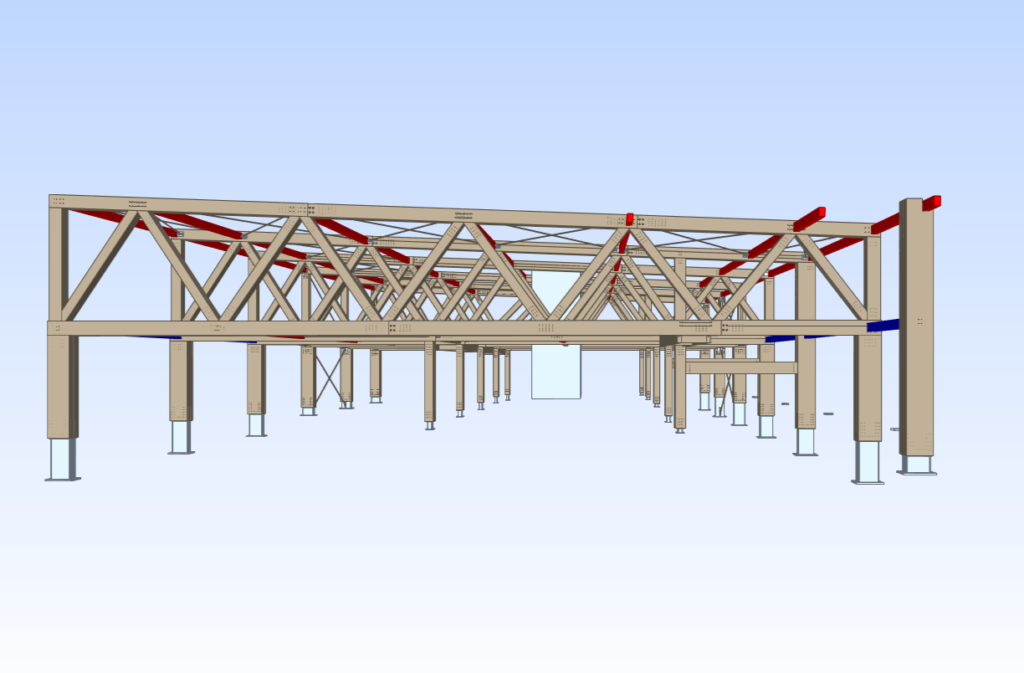

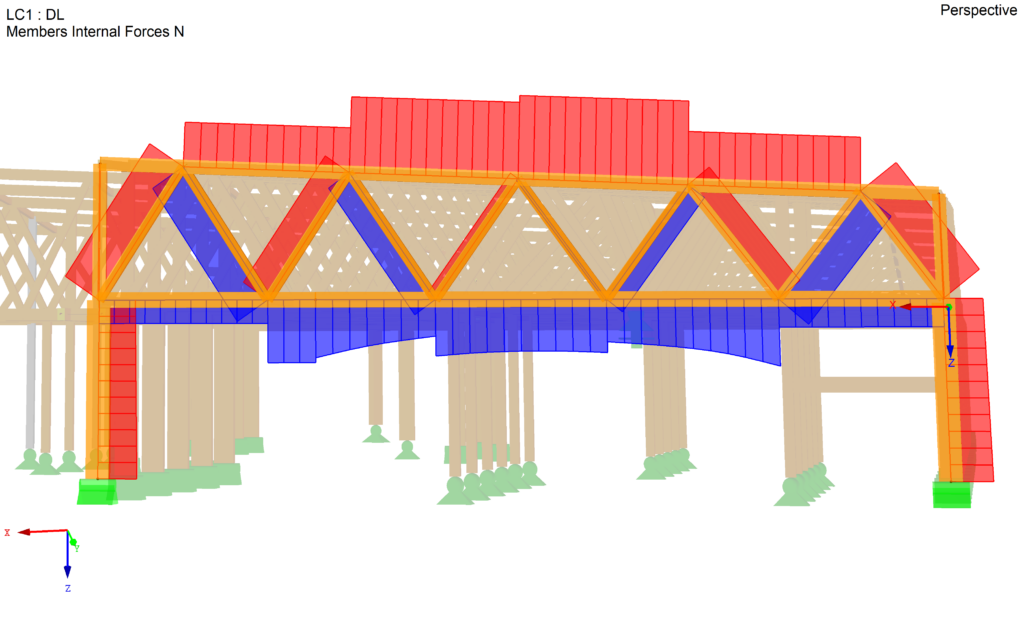

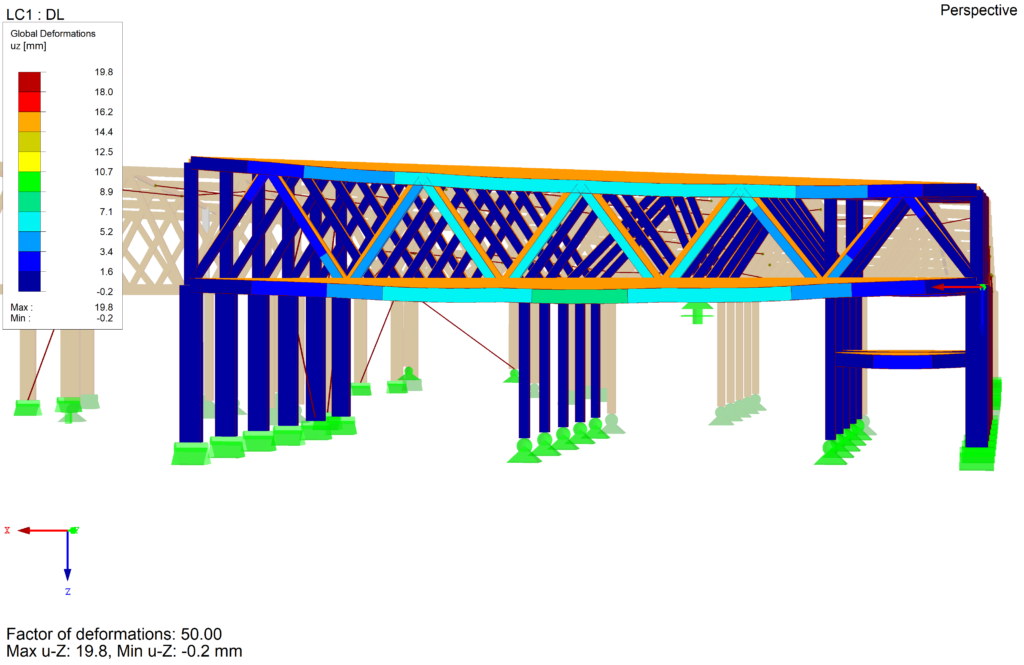

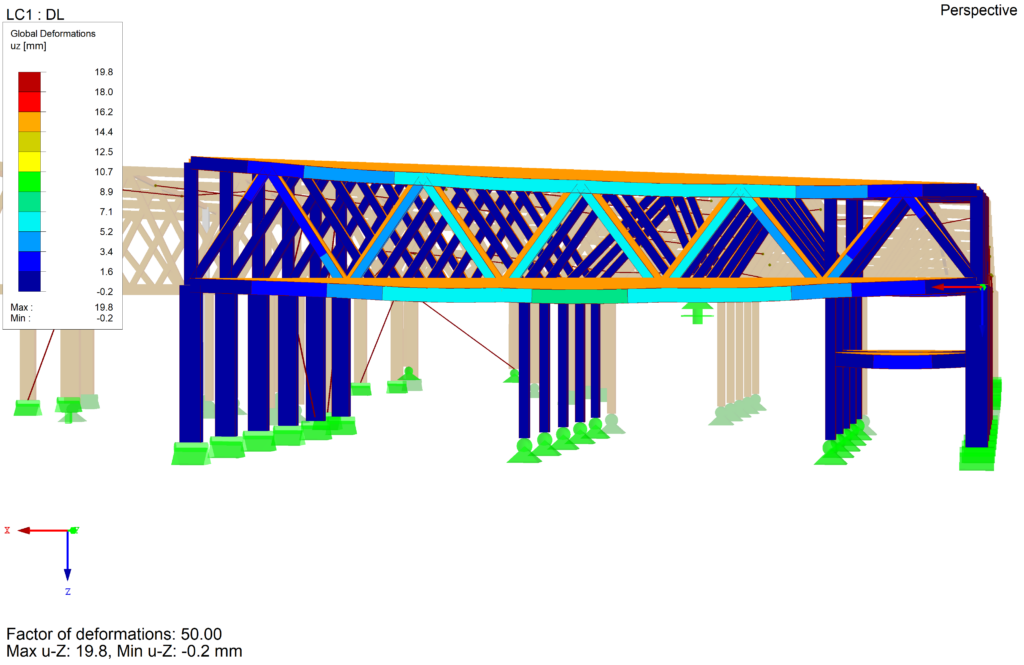

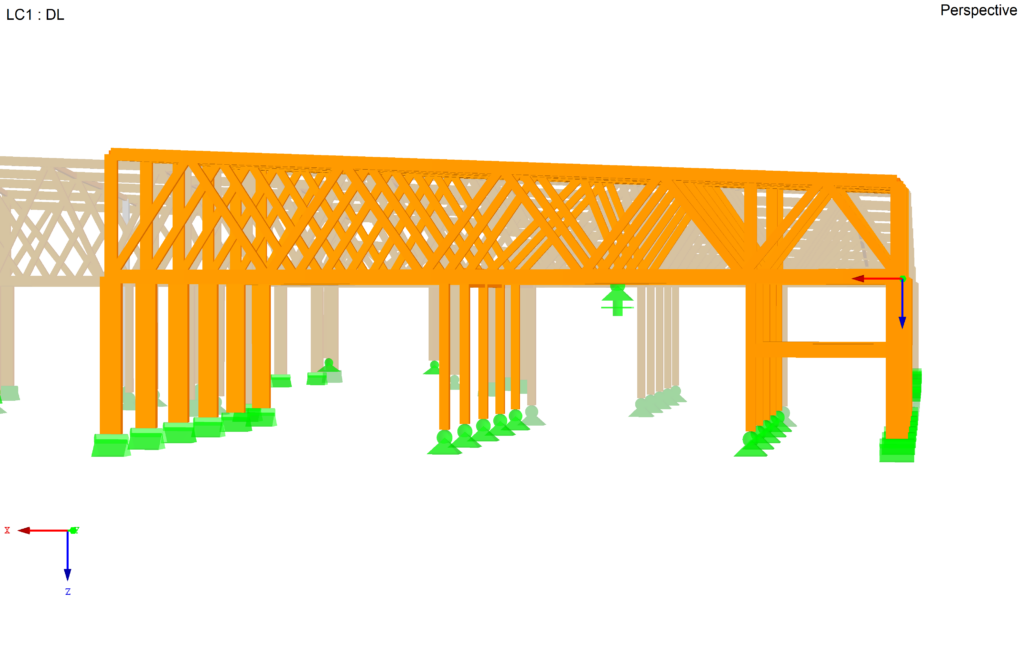

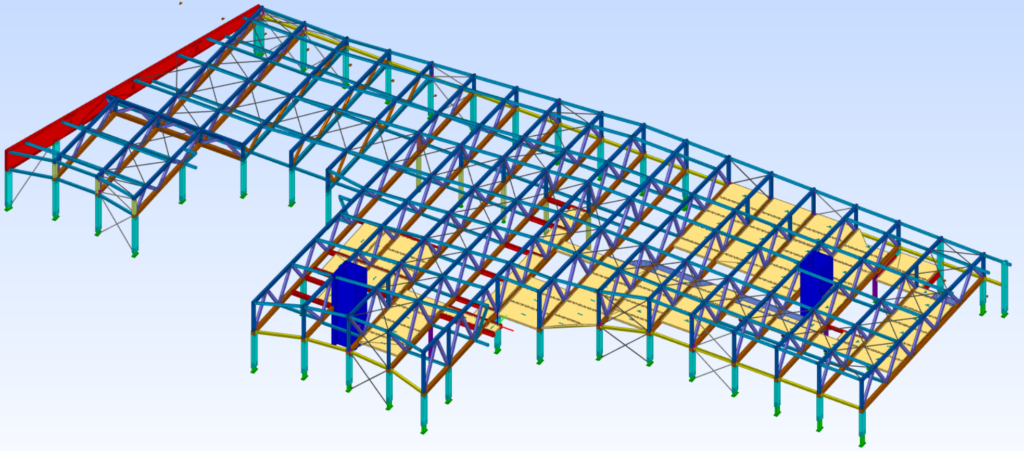

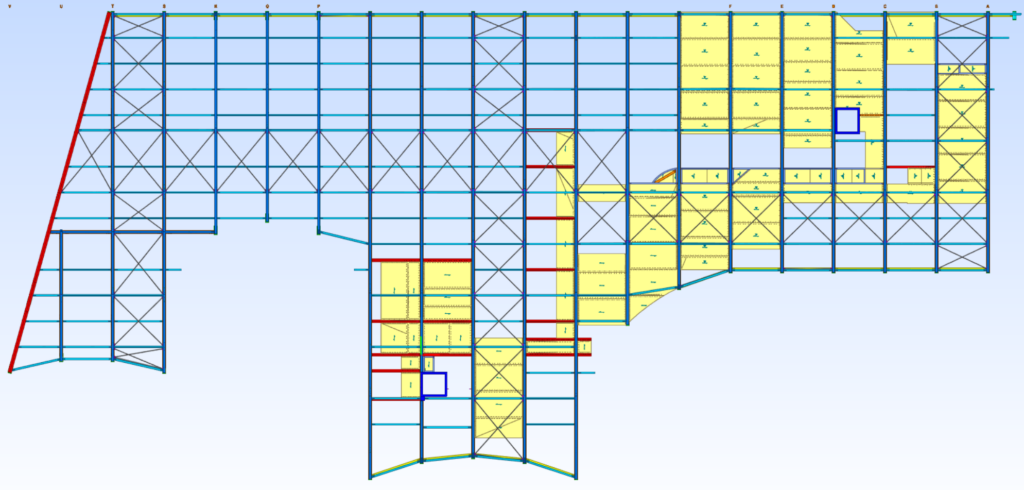

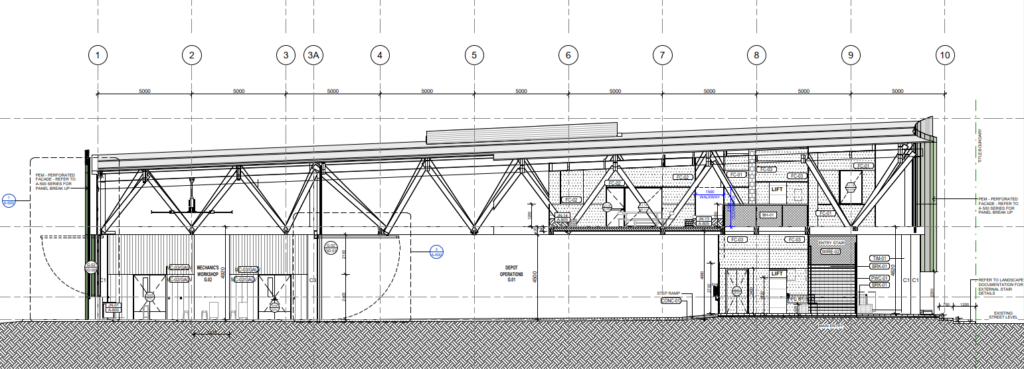

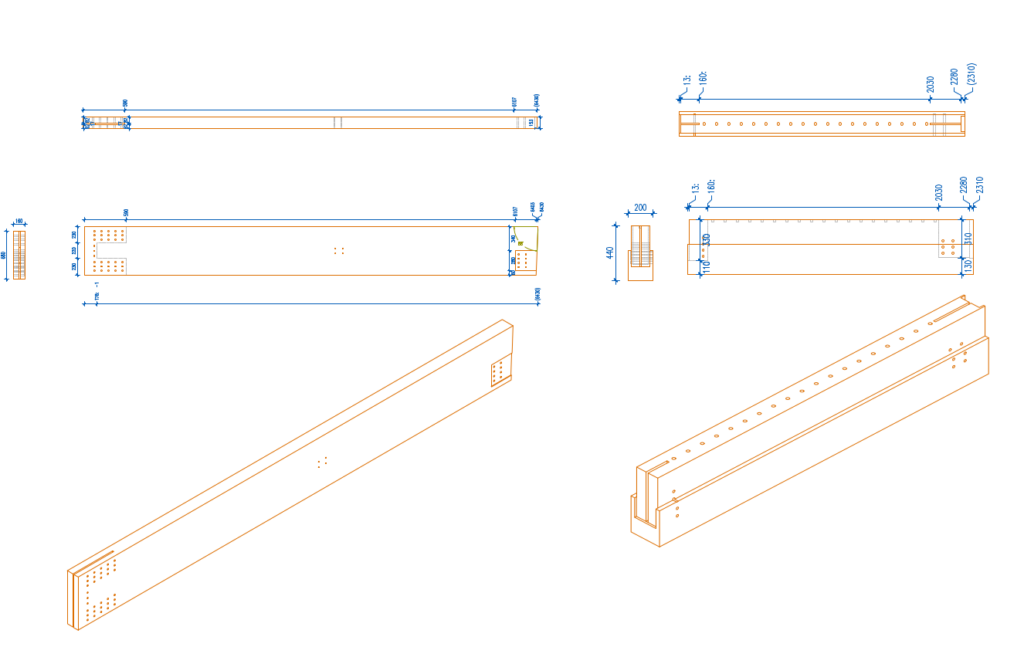

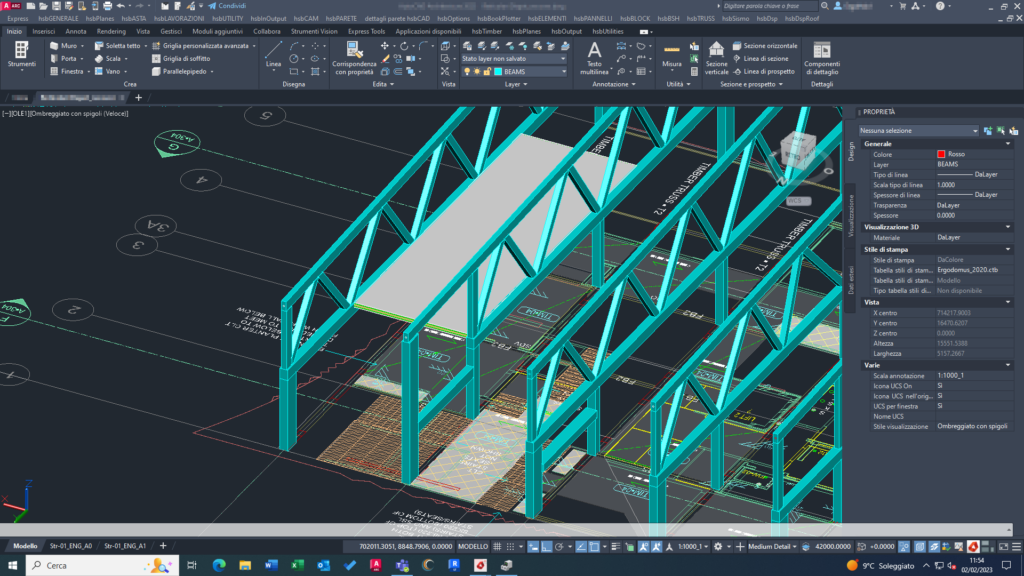

An Architectural Marvel with Massive Timber Trusses

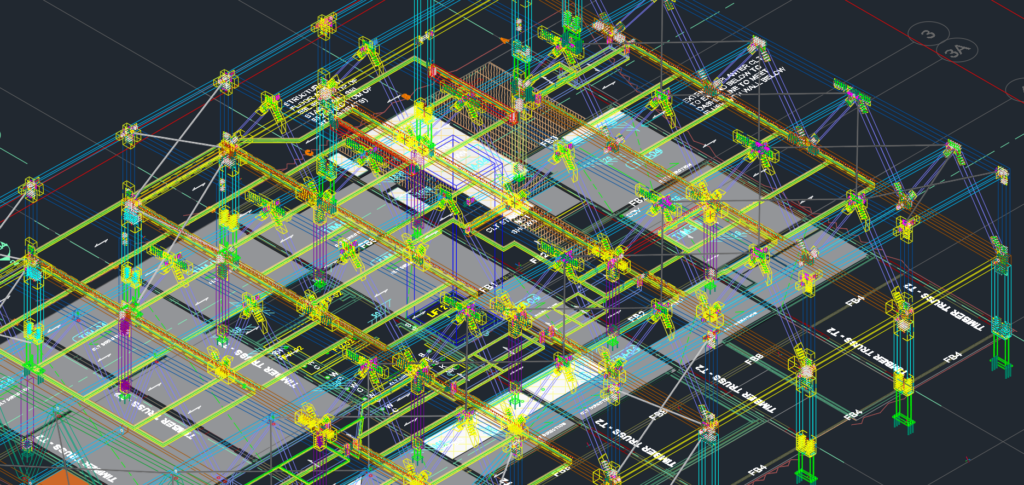

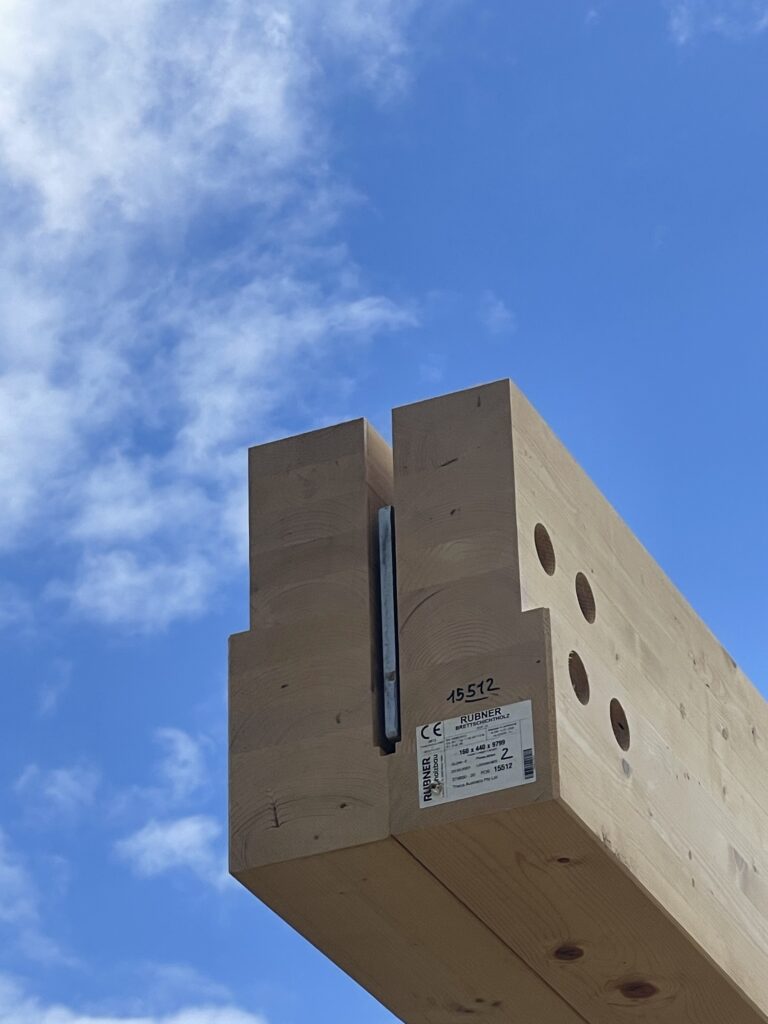

At the heart of the depot’s design is a series of 20 complex glulam timber (GLT) trusses of varying heights and configurations. These trusses are so substantial that they house offices between the lower and upper chords, creating unique and functional workspaces. While the structures might superficially appear repetitive, in reality, every single truss is different and presents its own challenges, requiring bespoke engineering solutions.

Innovative CLT Floor Slabs Creating Rigid Diaphragms

The horizontal slabs made of Cross-Laminated Timber (CLT) are ingeniously designed with openings, allowing visual connectivity between floors. The CLT panels work exceptionally well to create a rigid diaphragm, enhancing the building’s structural integrity and its ability to distribute loads effectively. From above, one can see the people working below, enhancing the sense of community and openness within the building.

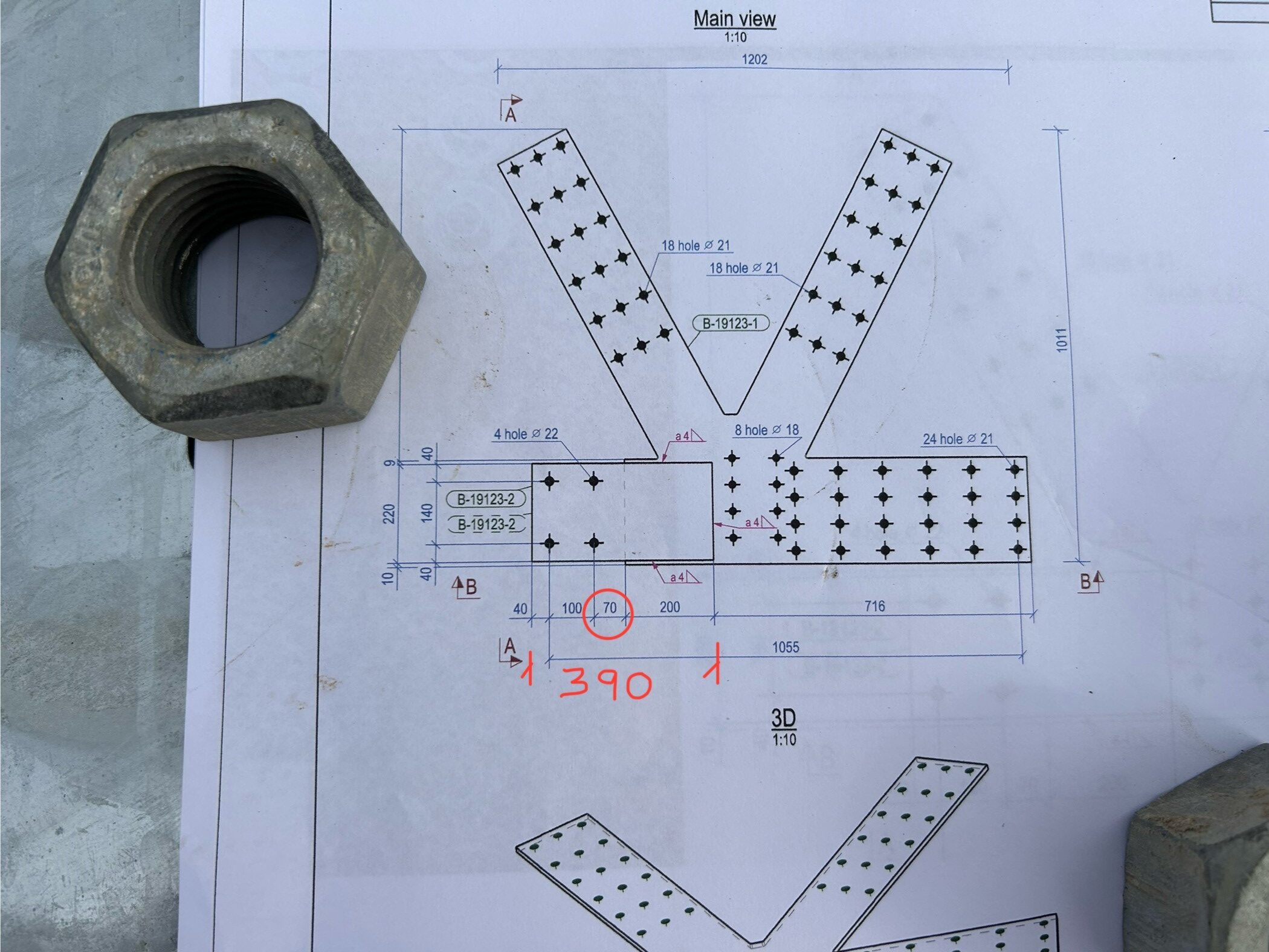

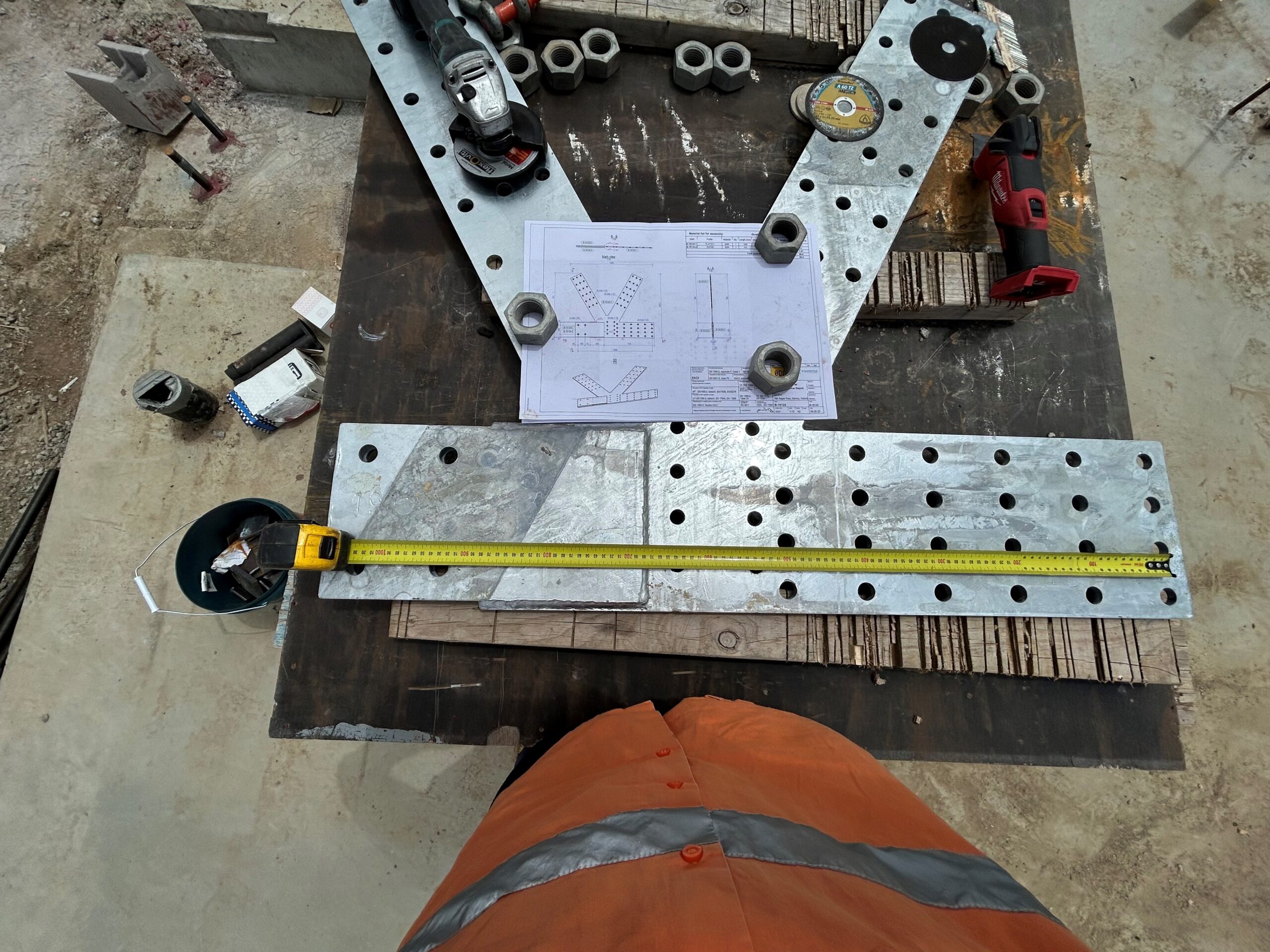

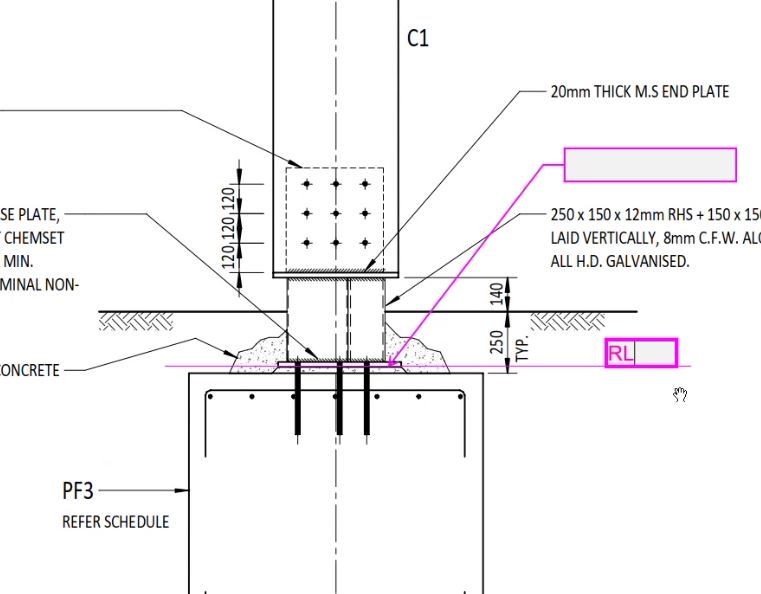

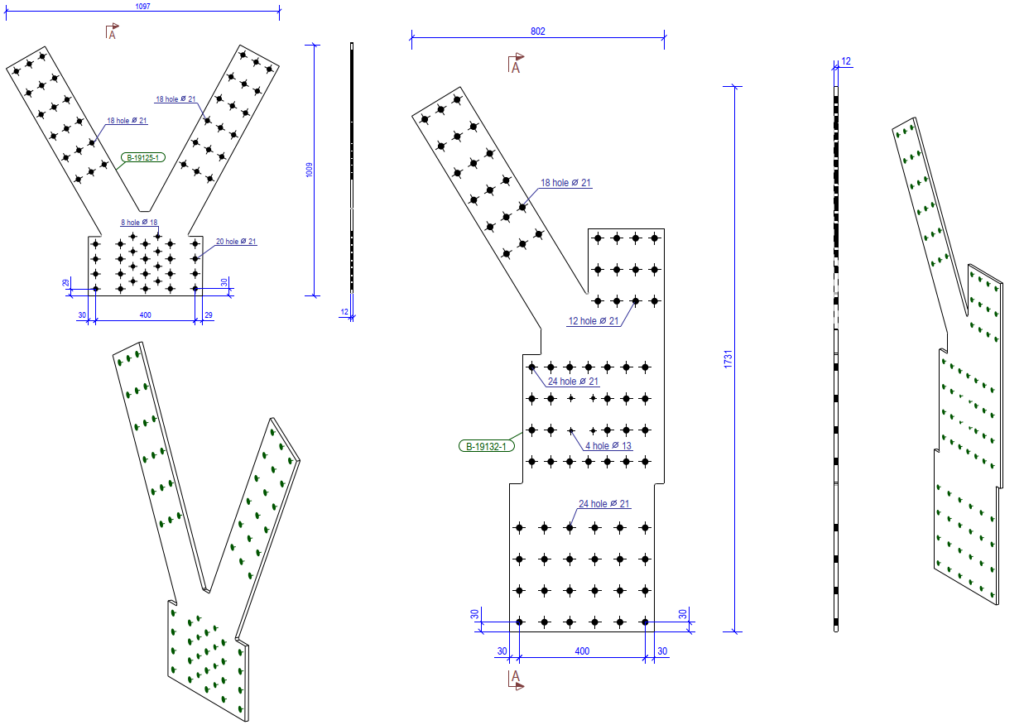

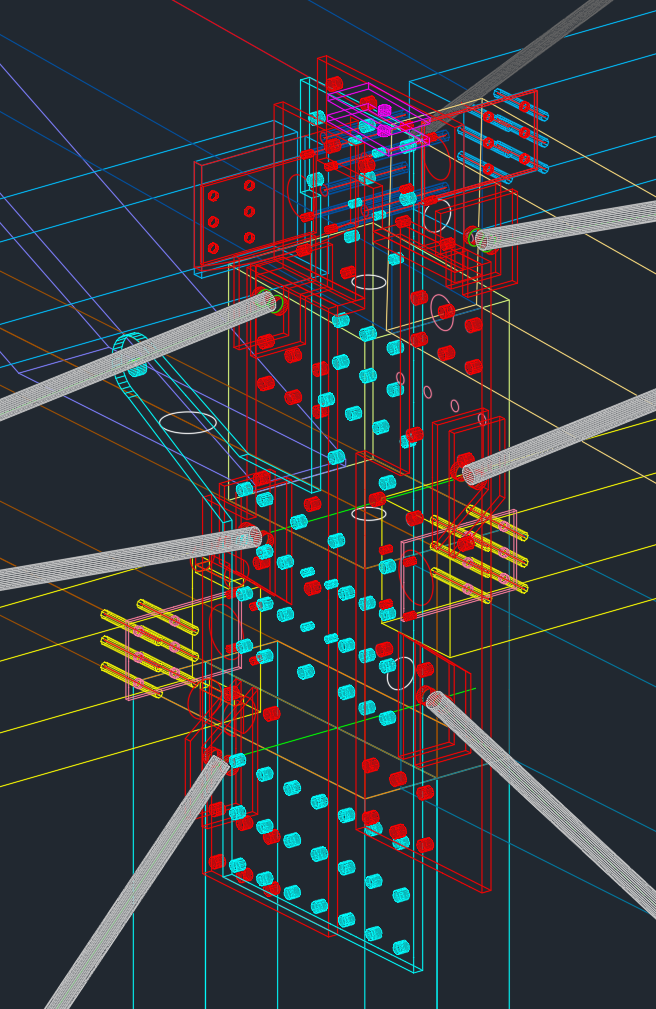

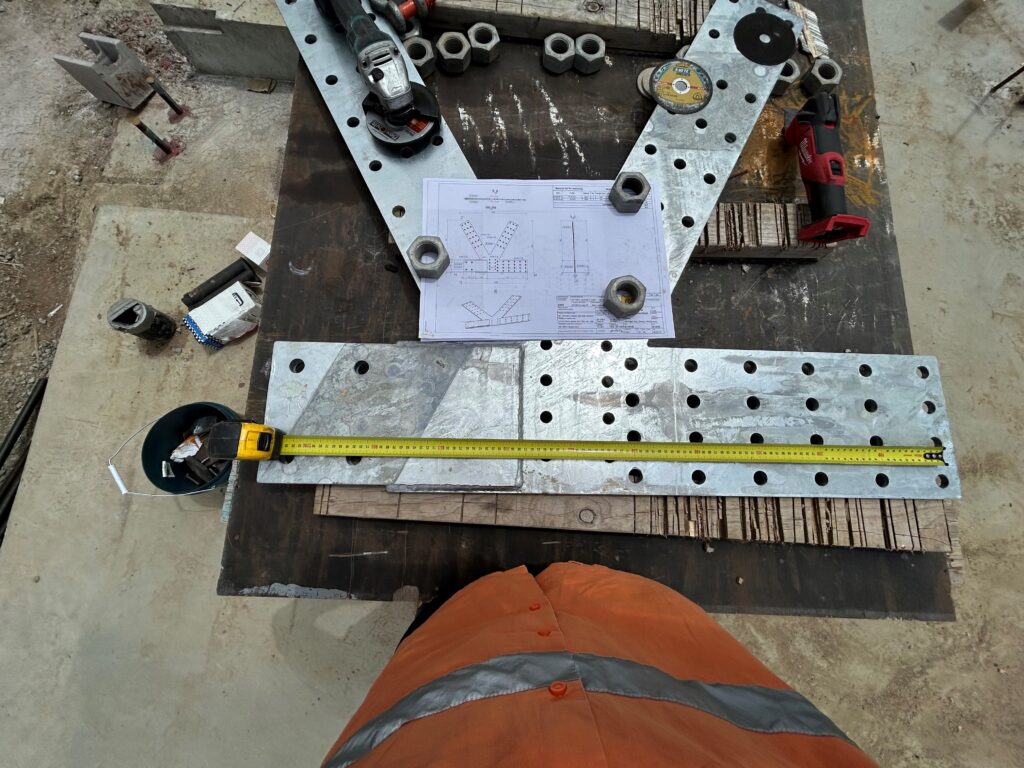

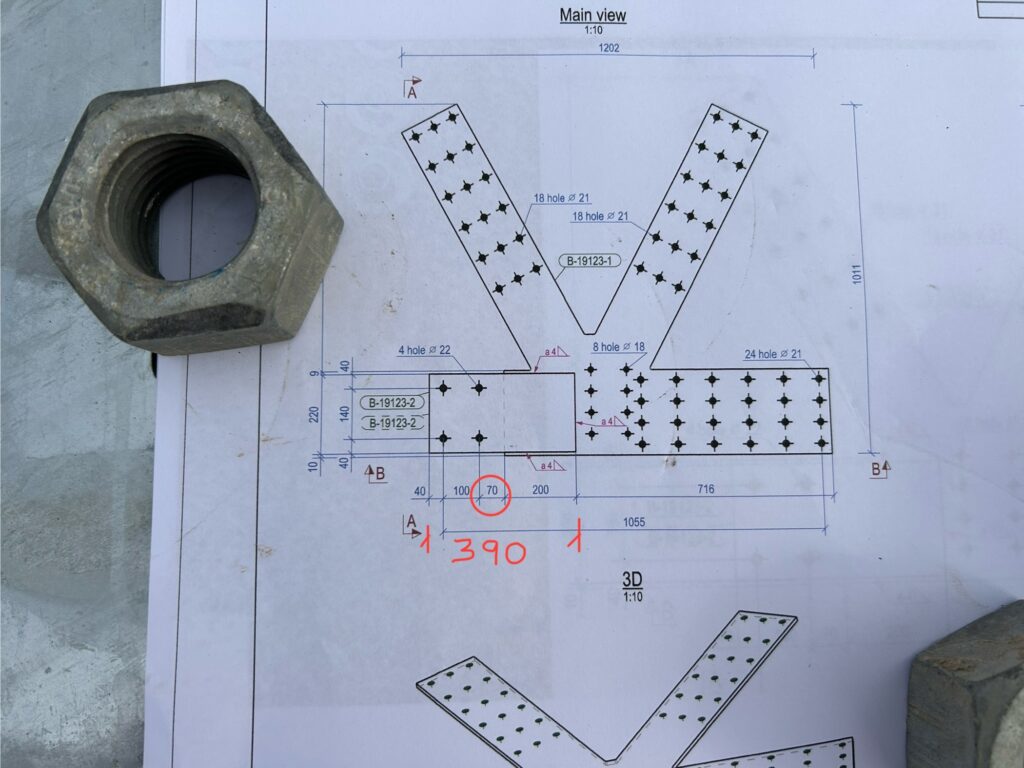

Sophisticated Bracing and Hidden Connections

A bracing system made of steel rods ensures the building’s stability against lateral forces such as wind and earthquakes. The timber-timber and timber-concrete connections are crafted using custom slotted steel plates with dowels and bolts. All steel connections are meticulously designed to be hidden, preserving the aesthetic appeal of the timber structure.

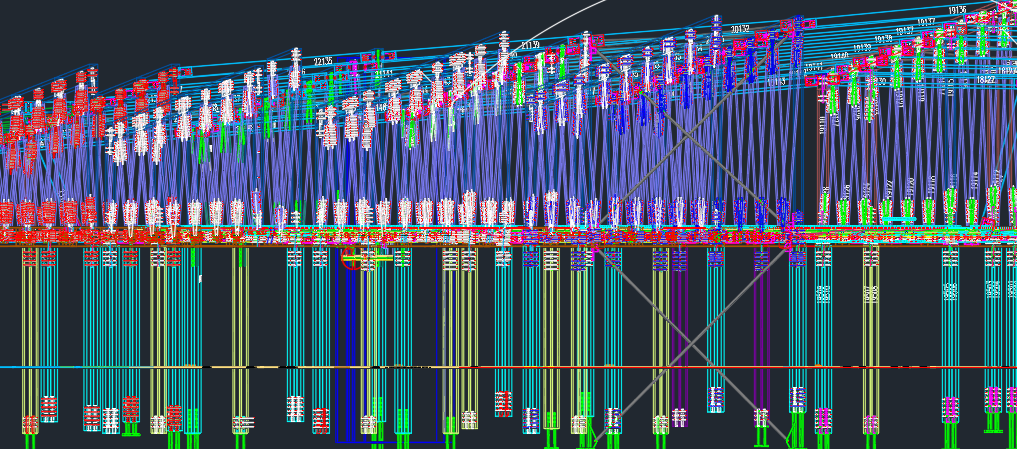

Our Scope of Work

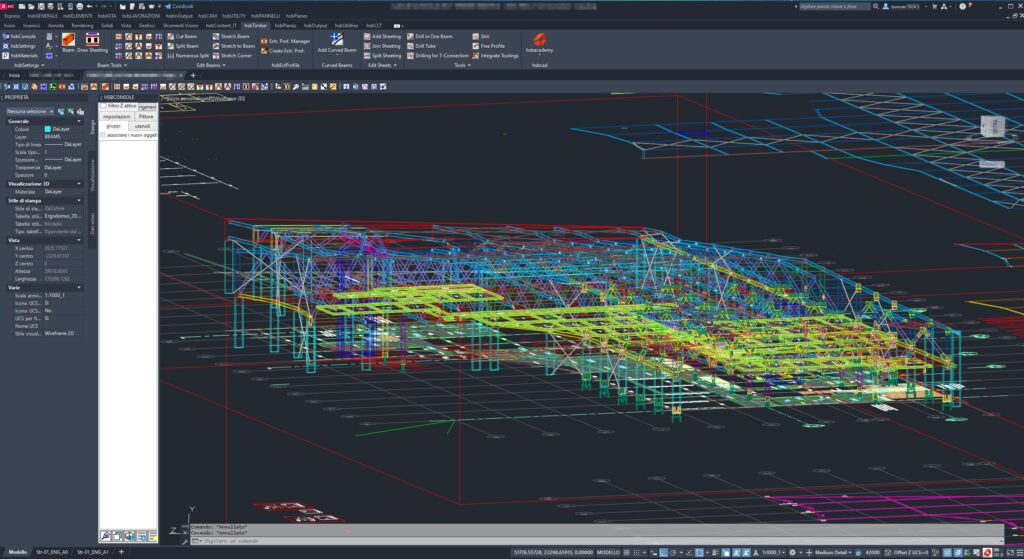

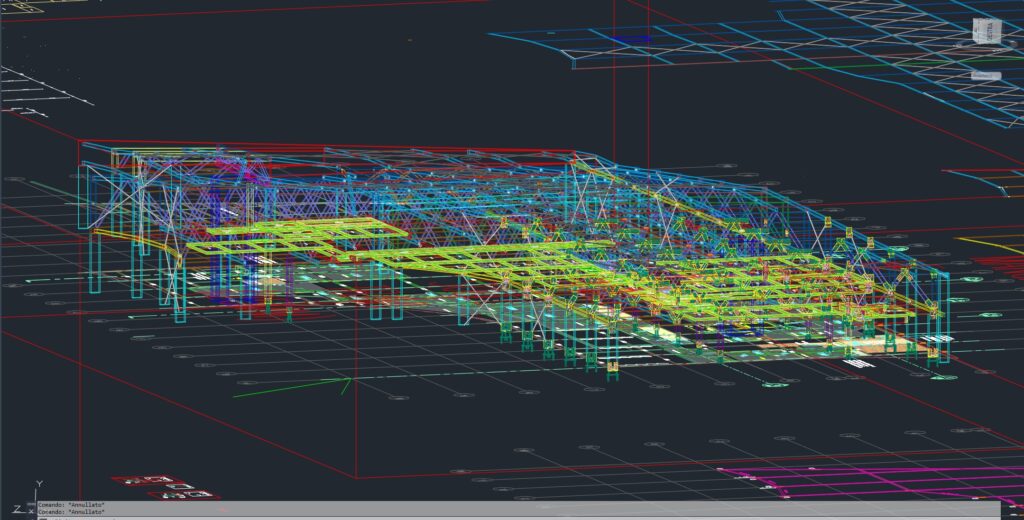

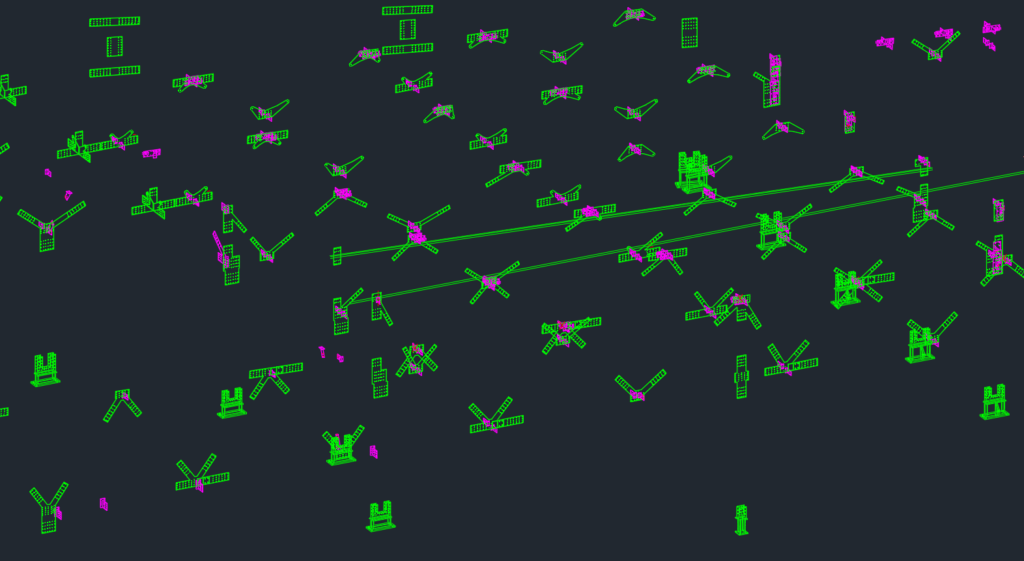

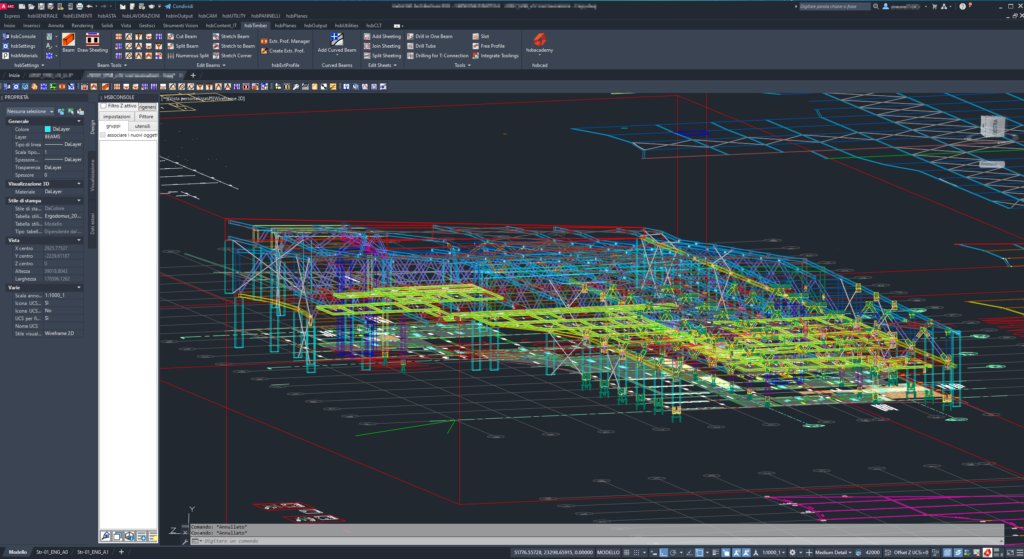

Ergodomus Timber Engineering played a pivotal role in this project, managing numerous aspects with precision and expertise: Advanced BIM Workflow, Production Drawings up to LOD 400, Connection Design and Detailing, Finite Element Method (FEM) Analysis.

Look at the 3D Digital Model we made

We shared this Digital Model via Speckle

Adherence to International Codes and Standards

In designing this complex structure, we applied a combination of international codes:

Eurocode 5 for the design of timber elements.

Eurocode 3 for steel components.

Australian Building Code for loads and specific requirements.

Our ability to navigate and integrate different building codes demonstrates our versatility and commitment to meeting local standards while leveraging global best practices. This multi-code approach ensured that the structure met all necessary regulations and performance criteria.

Off-Site Production and Logistical Expertise

All timber elements were produced in Europe and transported to Australia via shipping containers. We had to navigate limitations on the size of the elements due to transportation constraints. By embracing off-site construction methods and adhering to the Design for Manufacture and Assembly (DfMA) principles, we ensured that the components were manufactured with precision and assembled quickly and efficiently on-site.

Unique Challenges and Custom Solutions

The project presented unique challenges that required innovative solutions:

- Logistical Constraints: Due to the need to ship materials from Europe to Australia, we carefully planned the size and packaging of each component to fit within shipping containers.

- Time Zone Differences: Effective collaboration with the general contractor and other designers was made possible through regular weekly meetings at 6 a.m. Rome time, showcasing our dedication to seamless communication despite geographical distances.

- Non-Standard Trusses: Each of the 20 trusses was unique, requiring bespoke engineering and design solutions to address individual challenges.

Impressive Numbers Reflecting Project Scale

The Sages Road Depot project is notable not only for its innovative design but also for the sheer volume of materials managed:

- Glued Laminated Timber (GLT): 960 GLT pieces were used, amounting to 300 cubic meters and a total weight of 150 tons.

- Cross-Laminated Timber (CLT): 88 CLT pieces were utilized, totaling 140 cubic meters, weighing nearly 70 tons, and covering an area of 710 square meters.

- Steel Components: An incredible 2,500 custom steel components were crafted, underscoring the project’s hybrid construction approach that combines materials for optimum durability and performance.

Conclusion

The completion of the Sages Road Depot represents a significant achievement in the field of mass timber and hybrid construction. Through close collaboration with SxWA and Building Engineering, meticulous planning, innovative design, and the use of advanced technologies such as BIM and FEM analysis, Ergodomus Timber Engineering successfully delivered a building that is both functional and architecturally stunning.

Our commitment to off-site construction, adherence to international codes like Eurocode 5 and Eurocode 3, and application of the Australian Building Code for loads and specific requirements exemplify our ability to bridge global expertise with local standards.

This project underscores our dedication to pushing the boundaries of timber engineering, leveraging modern methods to create structures that meet complex requirements while maintaining aesthetic integrity. The hidden connections, massive timber trusses housing offices, and collaborative spaces all contribute to a building that fosters community and sets new standards in sustainable construction.

Gallery