In Oslo, a city often draped in the quiet beauty of winter, four new structures are taking shape. Built using modular units, Vestbyen’s buildings are set to welcome numerous families, offering them warmth and comfort.

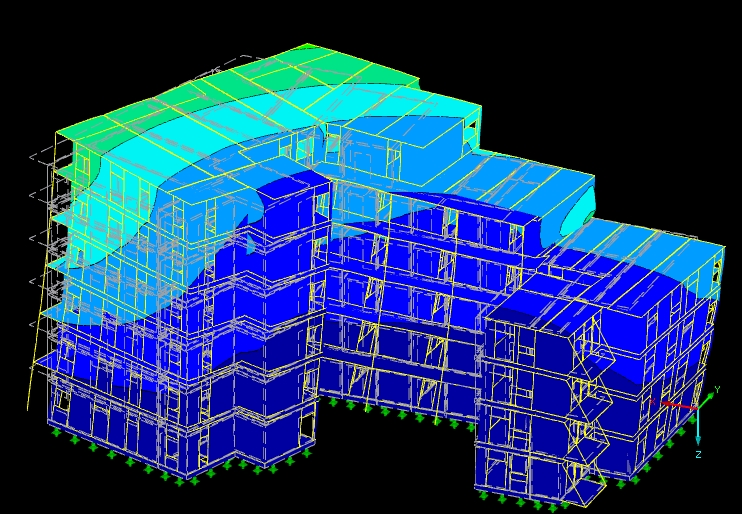

Timber at the Core: CLT Stair Shafts

Unlike many modular buildings where stair shafts are typically cast in concrete, Vestbyen takes a different approach. The stair shafts here are made of Cross-Laminated Timber (CLT), making it a building 100% made of Mass Timber. Every horizontal load is managed by the CLT core, creating a robust and resilient structure.

All the modules arrived on-site almost ready for immediate use! The level of prefabrication was exceptionally high, with all mechanicals already in place, walls painted, tiles and built-in furniture installed, and bathroom fixtures set up.

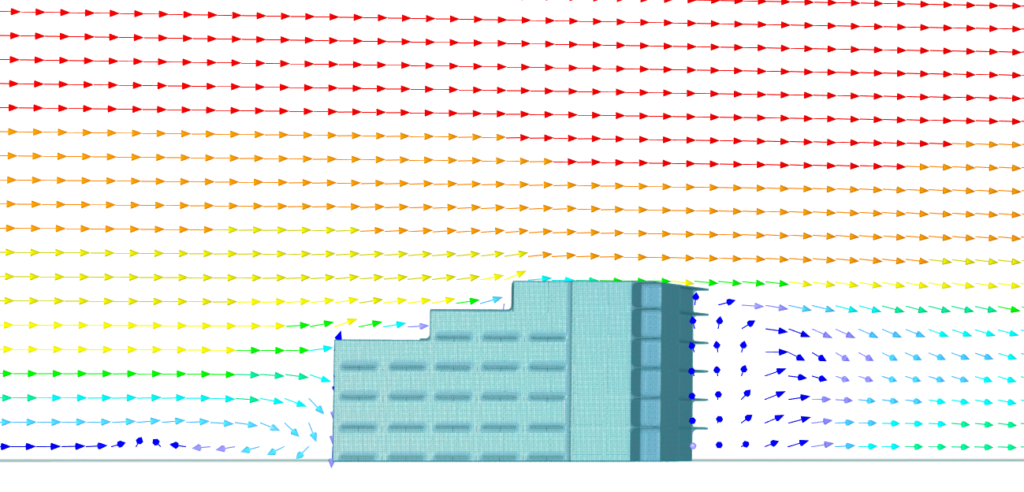

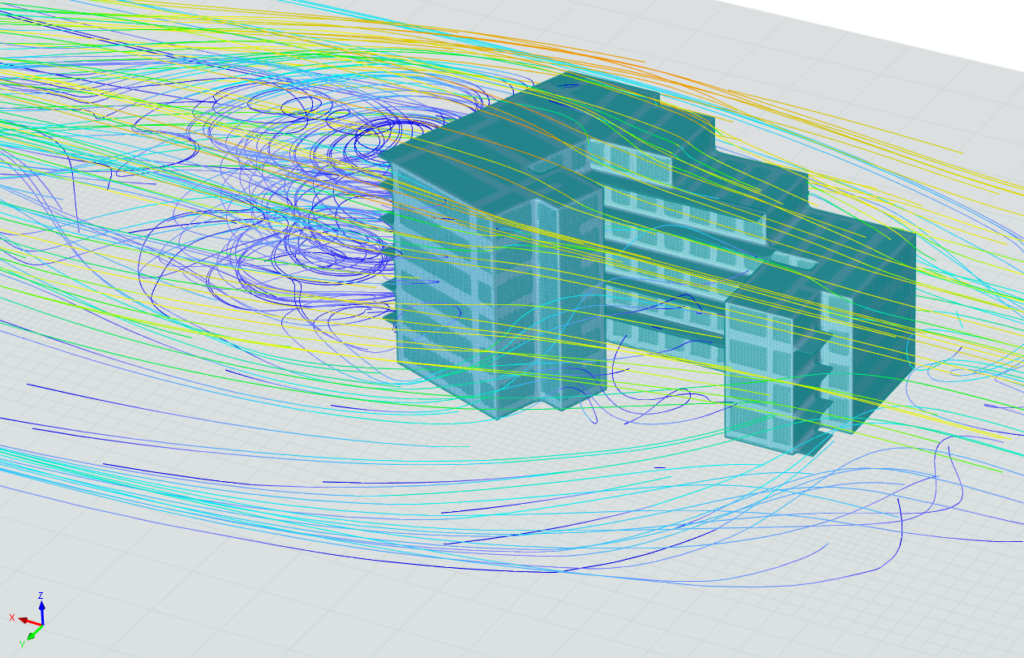

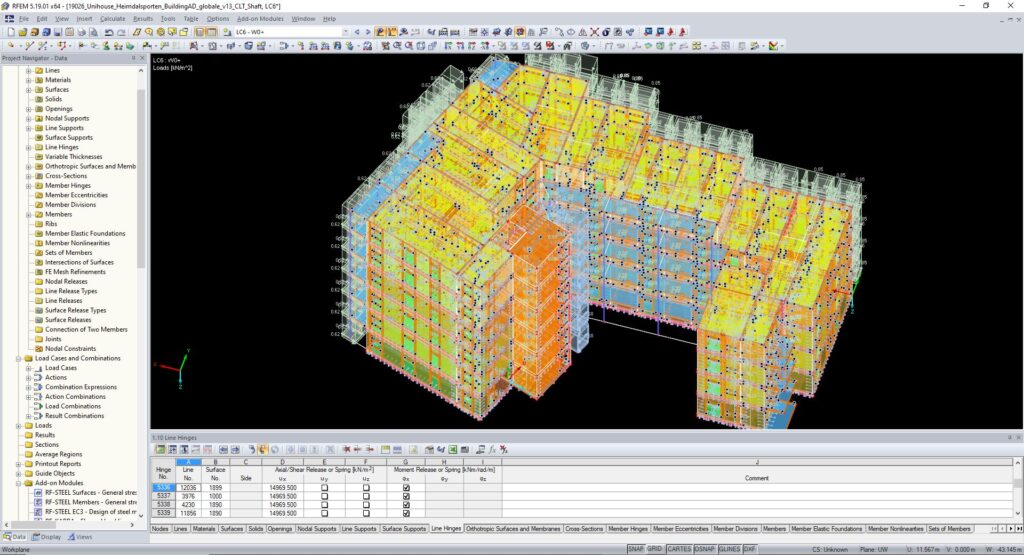

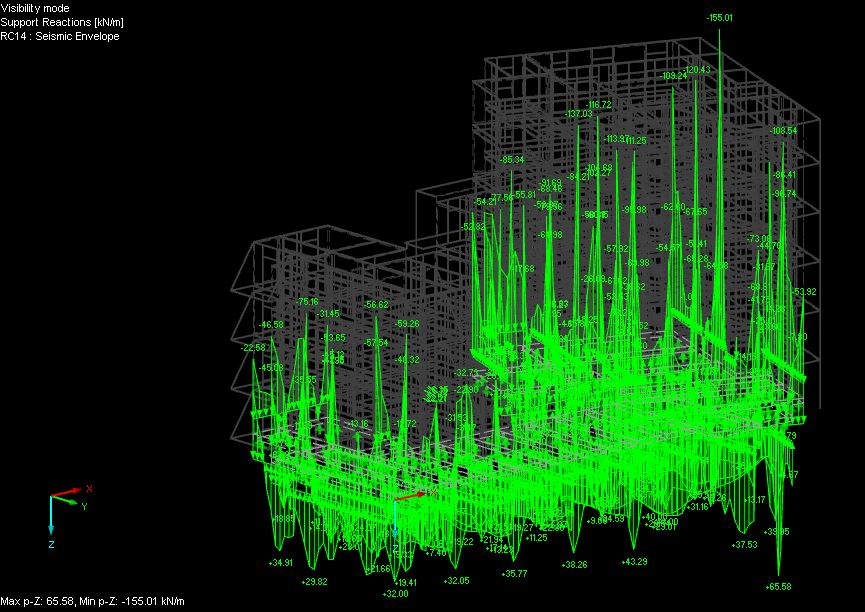

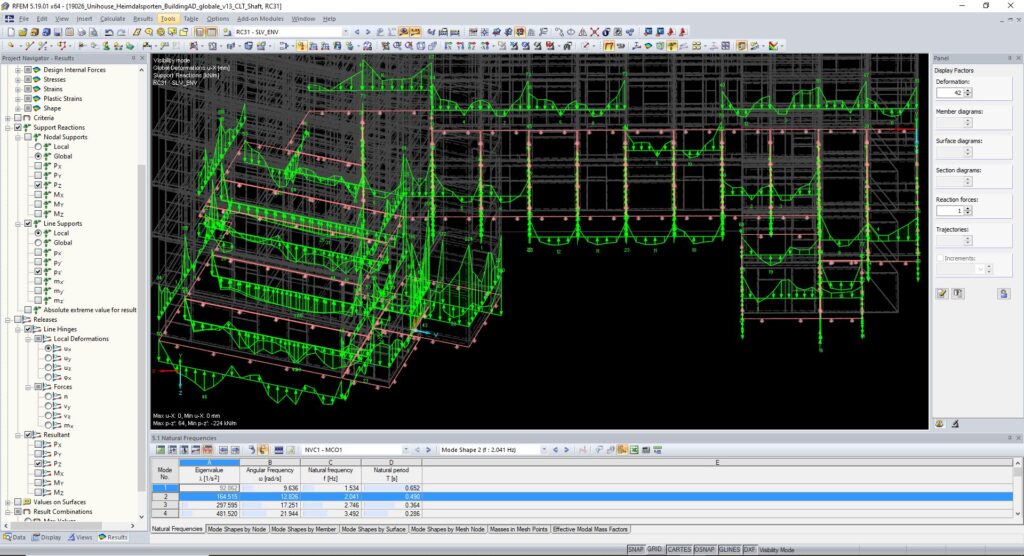

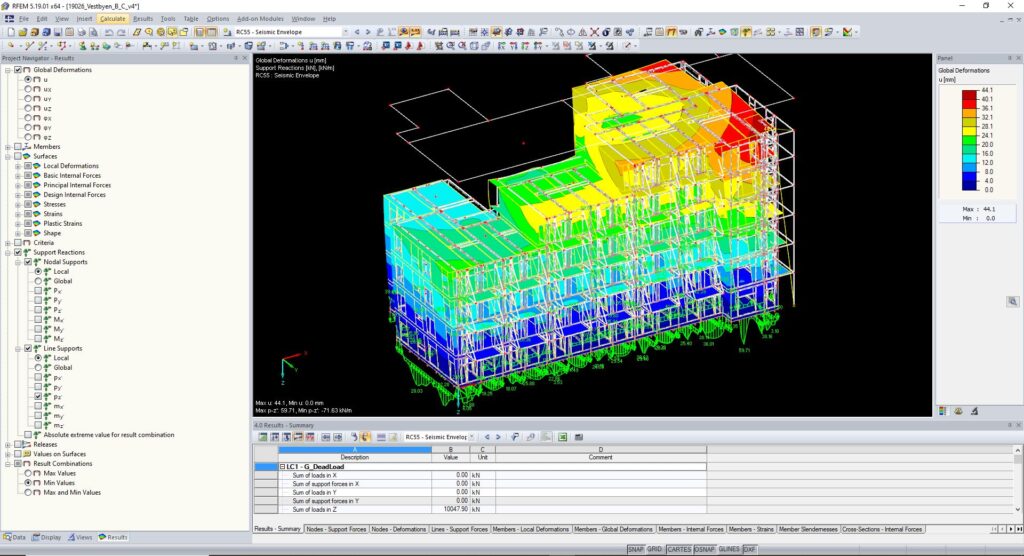

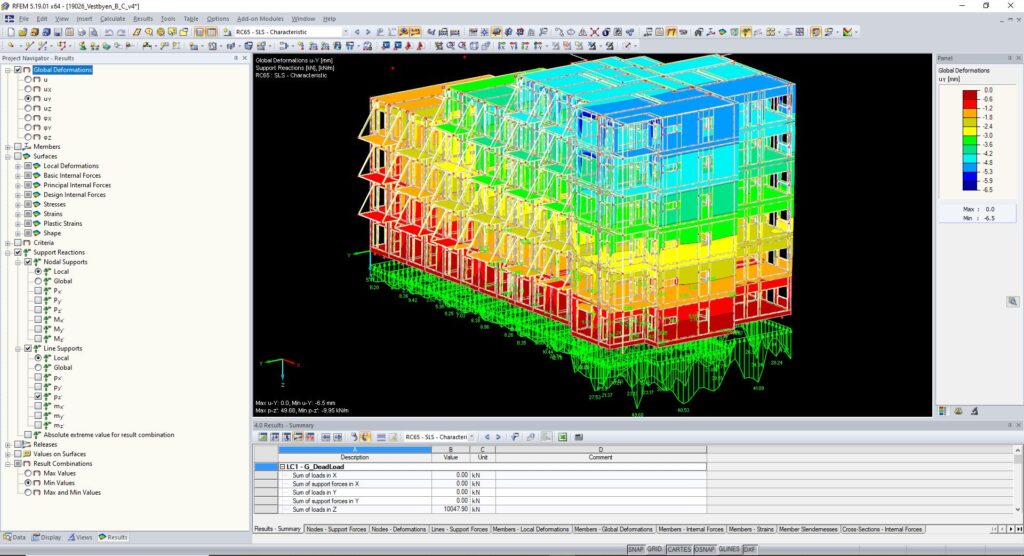

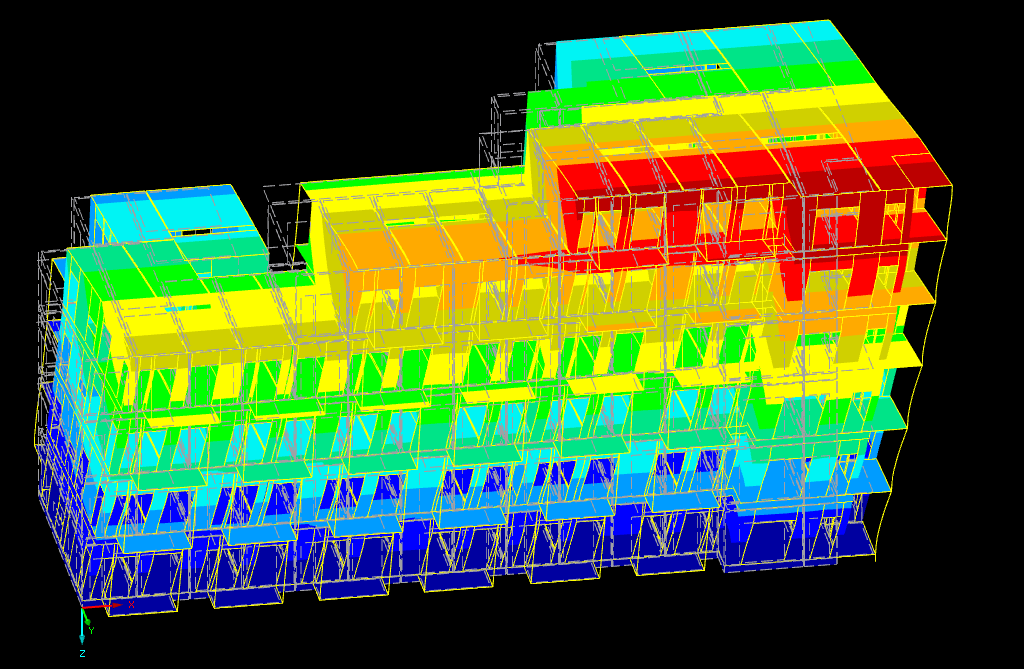

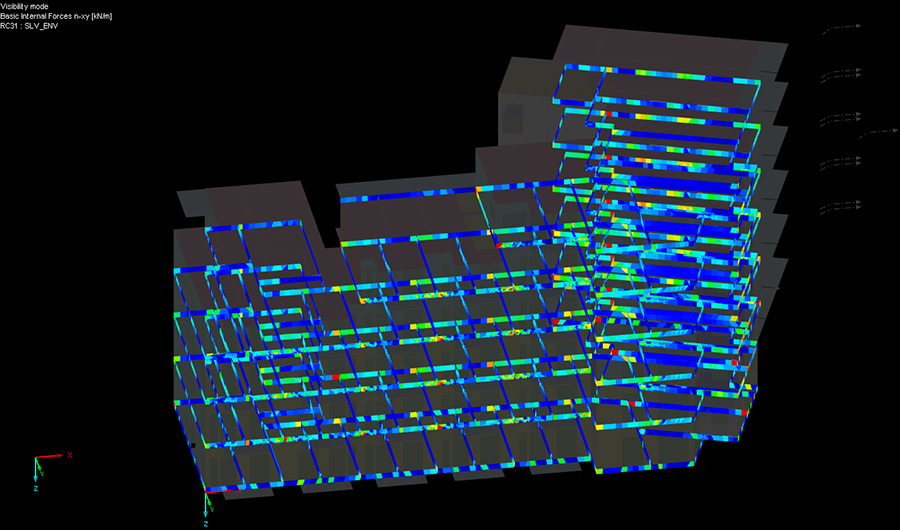

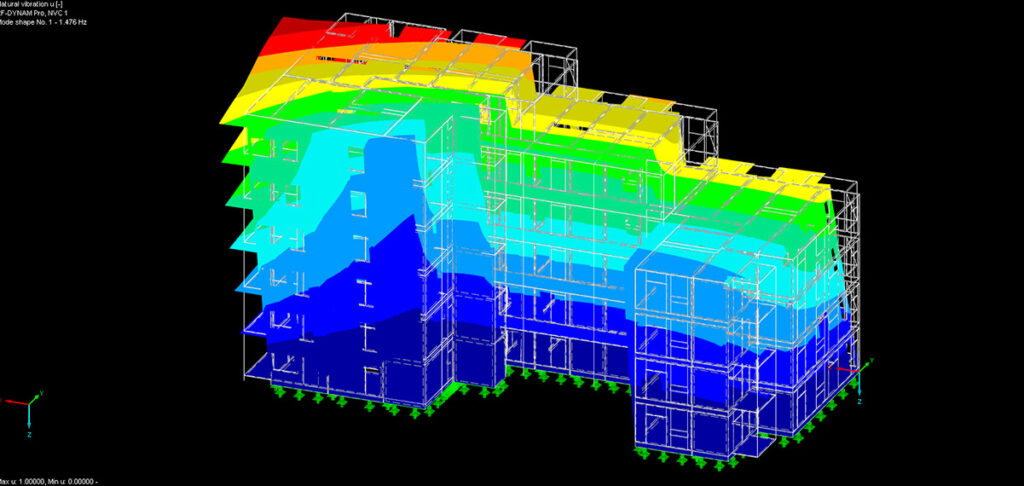

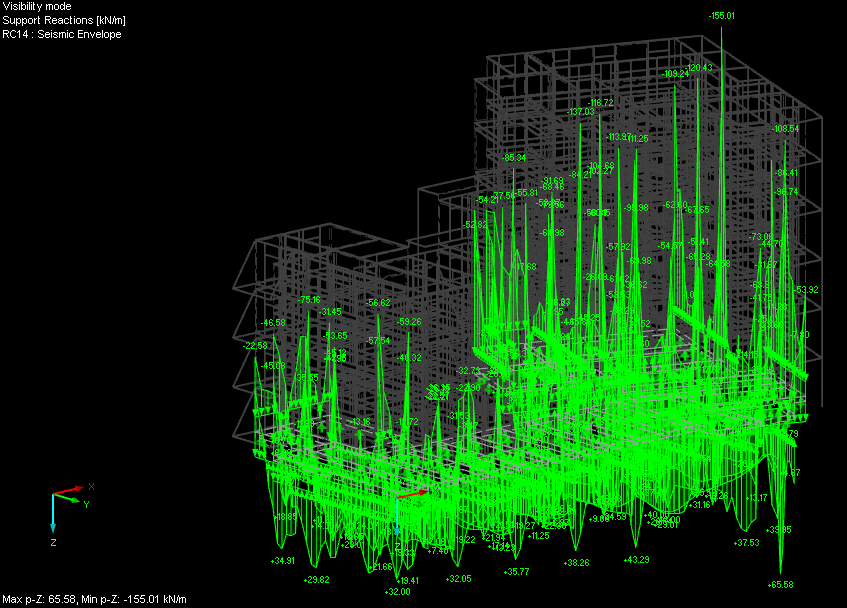

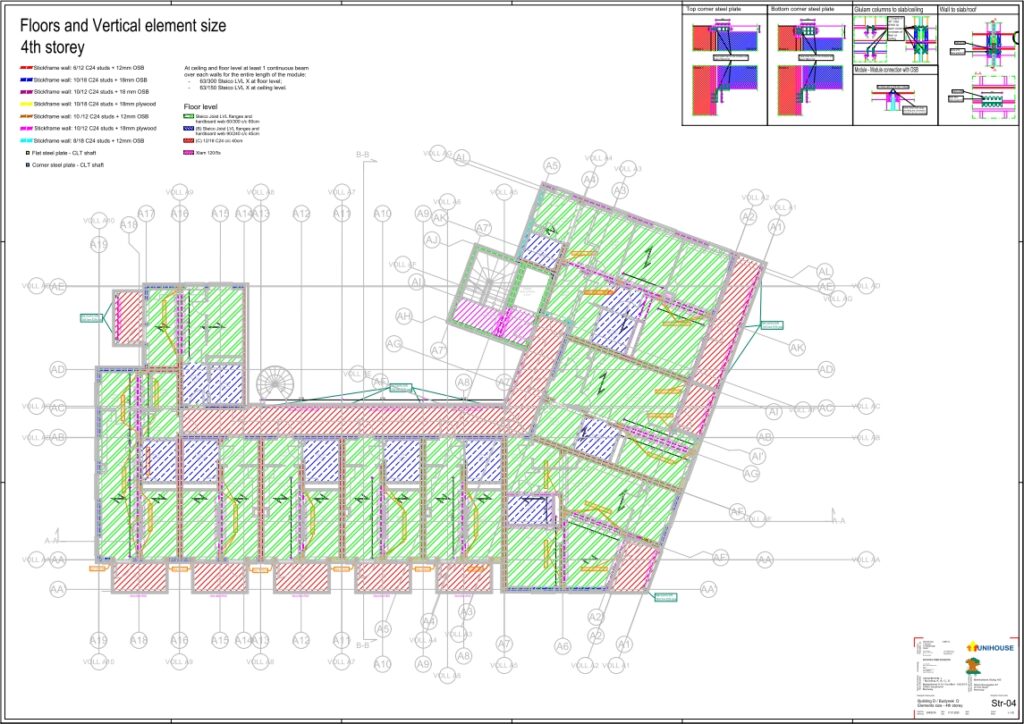

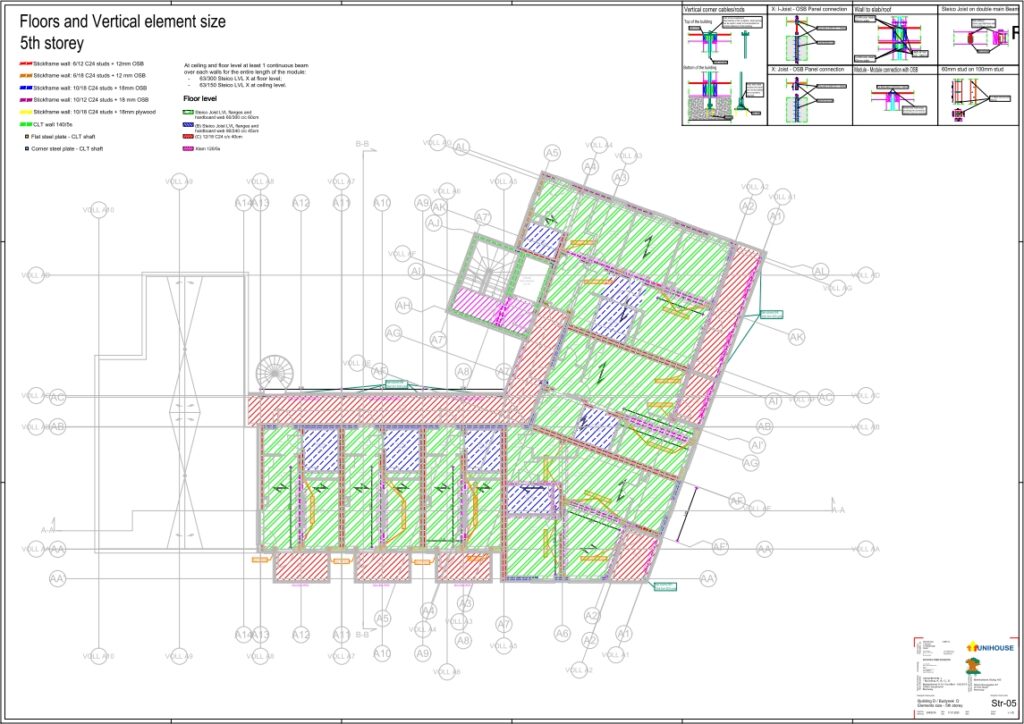

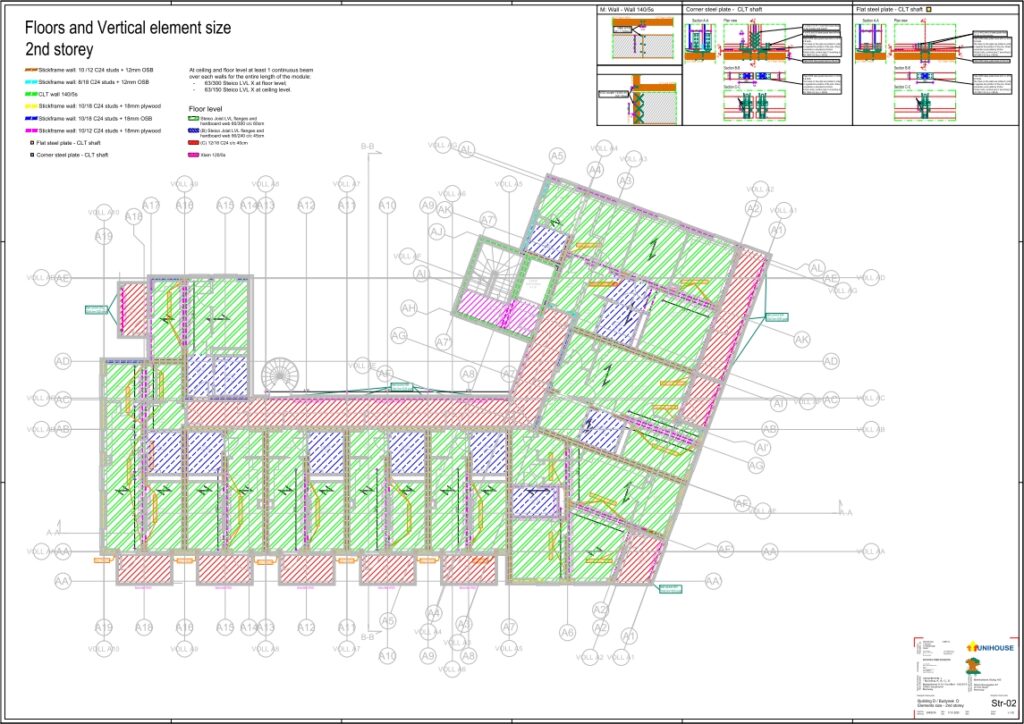

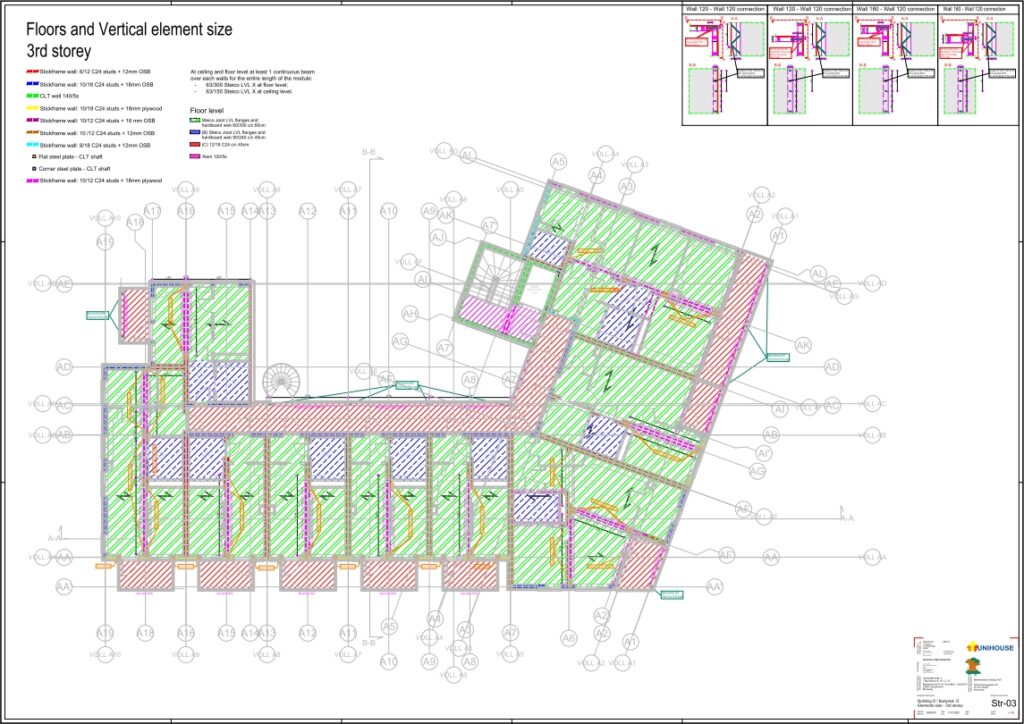

Precision in Structural Analysis

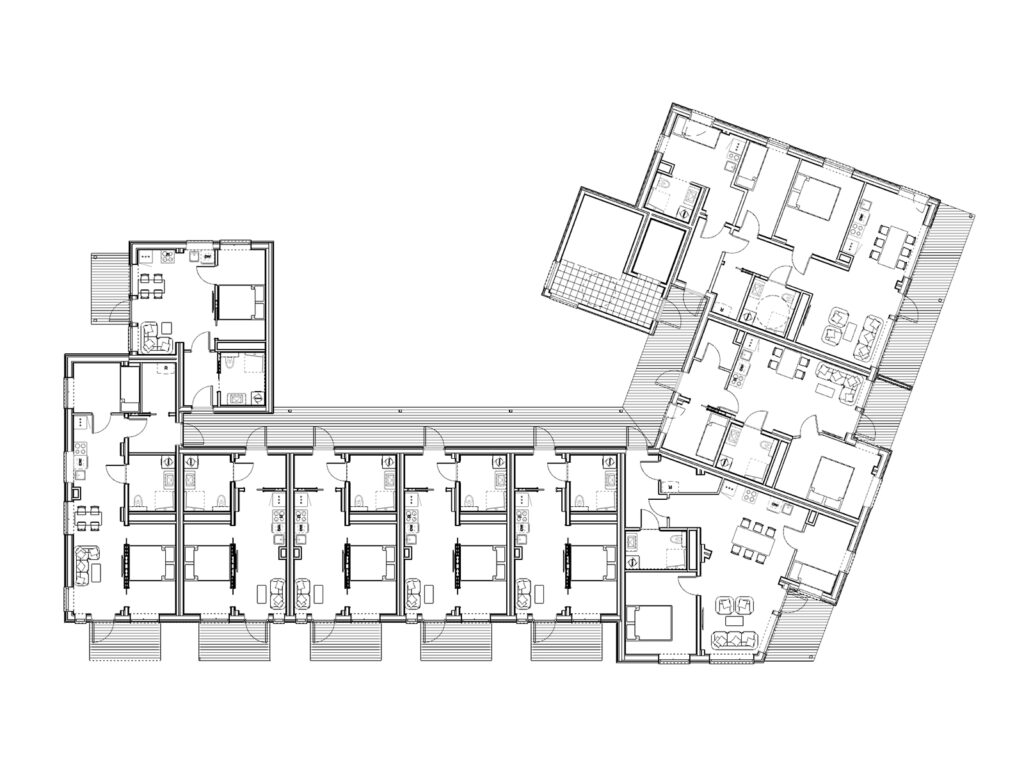

At Ergodomus, we oversaw the structural analysis, ensuring that every beam and connection is designed to withstand the challenges that come with such an ambitious project. These prefabricated modular units are ingeniously arranged around the timber cores, with meticulously designed steel connections that bear the progressively heavy downward loads as the building rises to approximately 20 meters.

Our Scope of Work

Here, you’ll find the engineering foundation behind Vestbyen. From load-bearing calculations to advanced modeling, take a journey through the technical efforts driving our designs.

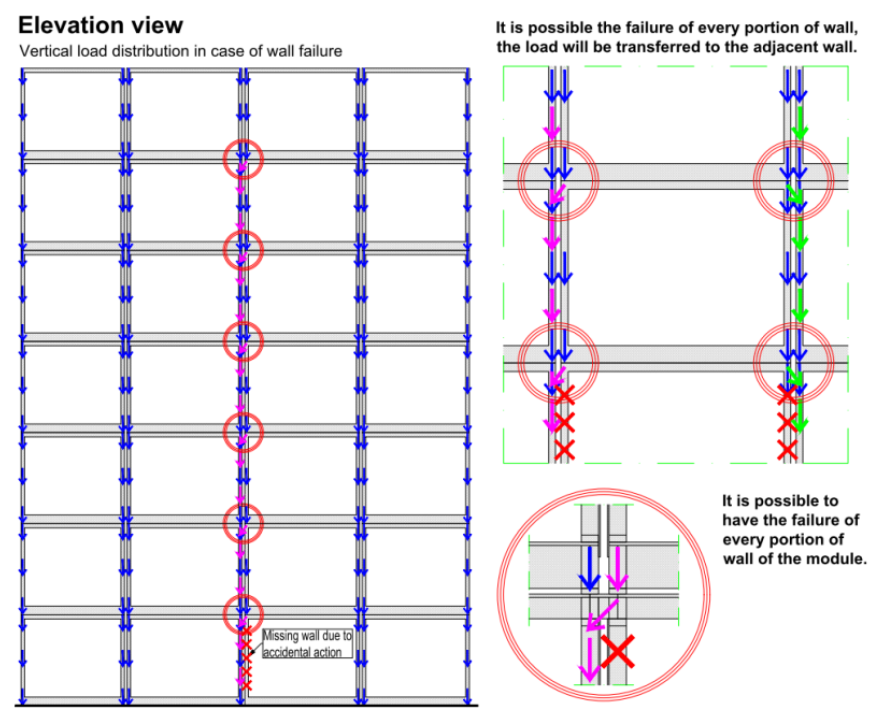

Engineering the Unexpected: Focus on the Robustness

But building something like this isn’t just about stacking modules and hoping for the best. We had to think ahead, anticipate potential problems, and focus on the buildings’ robustness (you can explore this idea further here https://www.ergodomus.it/2022/12/progressive-collapse-design-and-mola-kits/). Understanding and applying this principle is essential to prevent structural failures, like the one that occurred in London in 1968. In that case, a gas explosion led to the collapse of a load-bearing flank wall, which triggered a progressive collapse of a significant portion of the building, as depicted in the image on the left.

This is a good example of why a Timber Engineer, especially when working on this kind of structure, must foresee anything that might happen to ensure the safety of the residents.

After all, accidents can happen. When they do the safety of the people, the structure’s integrity must be our top priorities.

One of the challenges we considered was what would happen if an accidental force caused a wall to be compromised. Translated: what if there’s a missing wall? In many buildings, this could be a disaster. But here, the vertical load seamlessly shifts to the adjacent walls, maintaining the building’s strength and safety. It’s this kind of foresight and planning that transforms a good building into a great one.

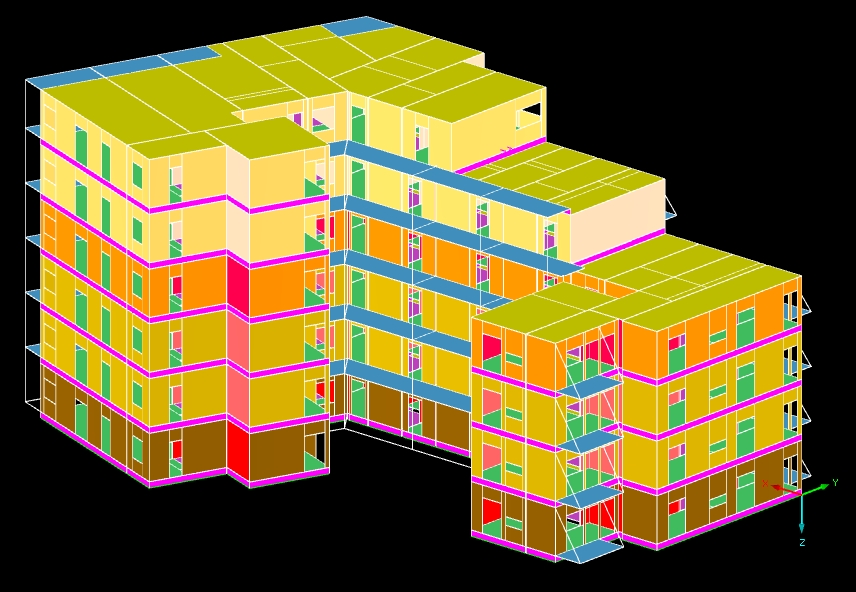

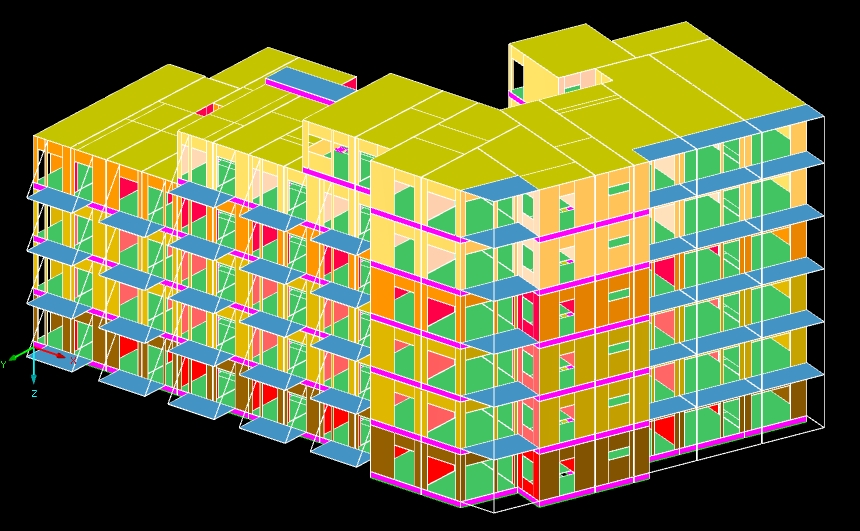

Look at the modules’ 3D Digital Model we made

We shared this 3D Digital Model via Speckle

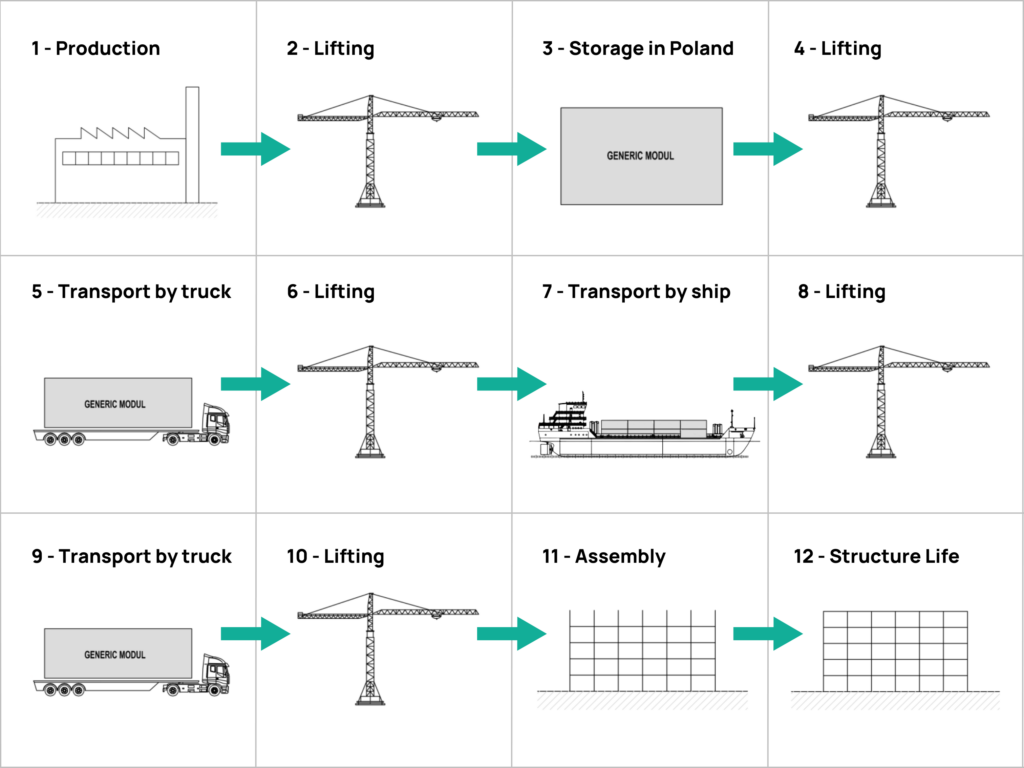

From Poland to Oslo: The Logistic of Vestbyen

The story of this building began beyond Norway’s borders. The 230 modules, crafted in Poland by UniHouse, before embarking on a journey by sea to their destination in Oslo. There, like pieces of a giant puzzle, they were carefully unloaded and assembled around the CLT stair shafts. Each piece fits perfectly into place, bringing the vision to life. The journey can be seen in the picture below.

FIFO and LIFO are very common acronyms in the building industry! First In First Out or Last In First Out?

UNIHOUSE SA

UniHouse SA is a Polish company specializing in modular construction, with a rich history spanning 70 years. We have collaborated with them on various occasions, including projects like Heimdalsporten.