DfMA (Design for Manufacture and Assembly) and Production Drawings are pivotal services tailored exclusively for manufacturers of advanced timber materials such as GLT, CLT, LVL, and more. At Ergodomus, we understand the unique challenges manufacturers face and offer a service that seamlessly integrates design precision with manufacturing efficiency. Our 20+ years of experience and holistic approach ensure that your production processes are optimized, reducing risks and enhancing overall project outcomes.

DfMA is like a “magician’s art” at Ergodomus. We aim to foresee potential on-site challenges and design assemblies that are easy and quick to implement, ensuring that your timber components are produced and assembled with precision and efficiency. Our proven track record and client trust demonstrate our ability to deliver high-quality, tailor-made solutions that meet the specific needs of manufacturers.

Why choose Ergodomus for DfMA and Production Drawings?

20+ Years of Expertise

Timber engineering is a specialized and relatively new field globally. With nearly two decades of extensive experience, Ergodomus stands as one of the few highly qualified experts capable of navigating the unique challenges of timber structures all over the world. Our dedication to innovative solutions ensures that each project delivers exceptional quality and value.

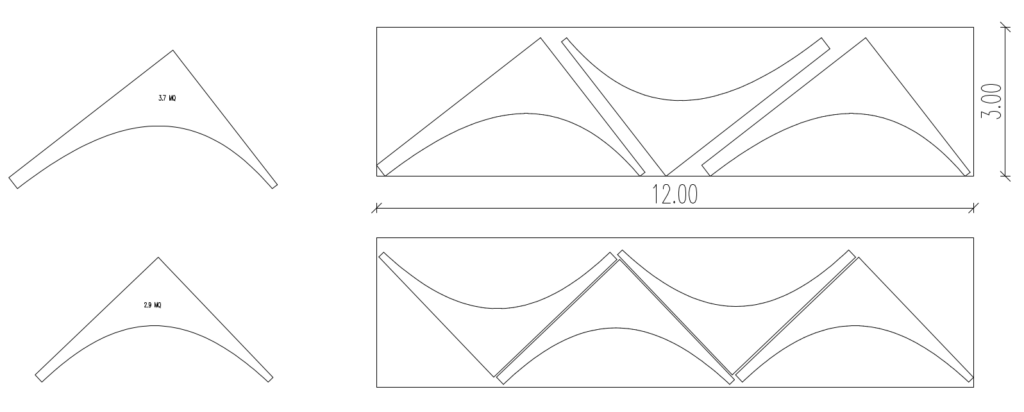

Hybrid Timber Structures

We excel in combining different structural timber-based materials to create timber hybrid structures. By mixing GLT, CLT, LVL, and other materials like steel and concrete, we optimize the performance and efficiency of your projects, ensuring that you get the most out of each material’s unique properties without sacrificing the aesthetic appeal of your structure.

Production Drawings at LOD 400

Production Drawings at Ergodomus correspond to LOD 400, a standard defined by building codes and ISO. This means they are fully detailed and ready for manufacturing, providing comprehensive information to ensure that every aspect of the timber elements and connections is meticulously planned and executed.

Ready for Production and CNC Machines

Our 3D files are not only production-ready but can also be directly used for CNC machine programming.

This seamless integration accelerates the manufacturing process, reduces errors, and enhances precision, ensuring that your timber components are produced accurately and efficiently.

De-Risking Through Digital Modeling

Our DfMA process incorporates comprehensive de-risking strategies by utilizing 3D digital models, which serve as digital twins of your projects. This allows for thorough visualization and simulation of the assembly process, identifying and mitigating potential risks before they arise on-site.

Seamless Integration with Project Components

Our DfMA/Production Drawings service integrates seamlessly with our other services, including Structural Analysis, Detailing, and Project Management. This holistic integration ensures consistency, enhances efficiency, and maintains the overall integrity of your project from design to execution.

Proven Track Record and Client Trust

Despite initial skepticism about subcontracting production drawings, our long-standing experience and successful project completions have earned the trust of numerous manufacturers. We consistently deliver high-quality, precise, and efficient production drawings tailored to your specific needs.

Don’t navigate the complexities of timber engineering alone

Are you a manufacturer specializing in GLT, CLT, LVL, or other advanced timber materials skeptical about subcontracting your production drawings? Partner with Ergodomus to leverage our 20+ years of expertise and holistic approach. Let us transform your production processes with precision, efficiency, and exceptional quality, earning your trust through our proven track record.

Experience the difference that expert DfMA and Production Drawings can make. Contact Ergodomus now and ensure your timber projects are executed flawlessly from design to assembly.