(and make timber the material to go for)

In the construction industry, there have always been numerous aspects to take into consideration from the very early stage of the projects that can deeply define the outcome and the of every project (including the economic/financial one). Among all, there is a specific aspect that has always had the first place in influencing the investors’ decisions and their willingness to invest capital: the risk.

The importance of risk management and, consequently, a de-risk approach became increasingly pivotal for mainly two reasons:

- the increase of players involved in the design/construction: architects, contractors, engineers (MEP, structural, etc…), and investors;

- the complexity related to the construction of each building, the increasingly stringent rules of the industry, and the building codes that have made each structure a complex organism. Remember: the devil is in the details.

Because of this, the industry will have to embrace Modern Methods of Construction (MMC) focused on off-site construction techniques, robotic prefabrication, modular buildings, and fast delivery.

The involvement of different actors, teams, and requests made risks grow exponentially in terms of time and cost. For this reason, it is important that all parties involved quickly understand the key role of sharing correct and real-time updated information through a professional and internationally recognized tool.

Here is where come in aid the BIM model and the highly efficient IFC files (we have deepened the role of IFC files in this article). The importance of sharing the files between the stakeholders and actors is notable in many of our projects, but there is a specific project where the ability to work on the same file with multiple actors has been the key factor for several reasons.

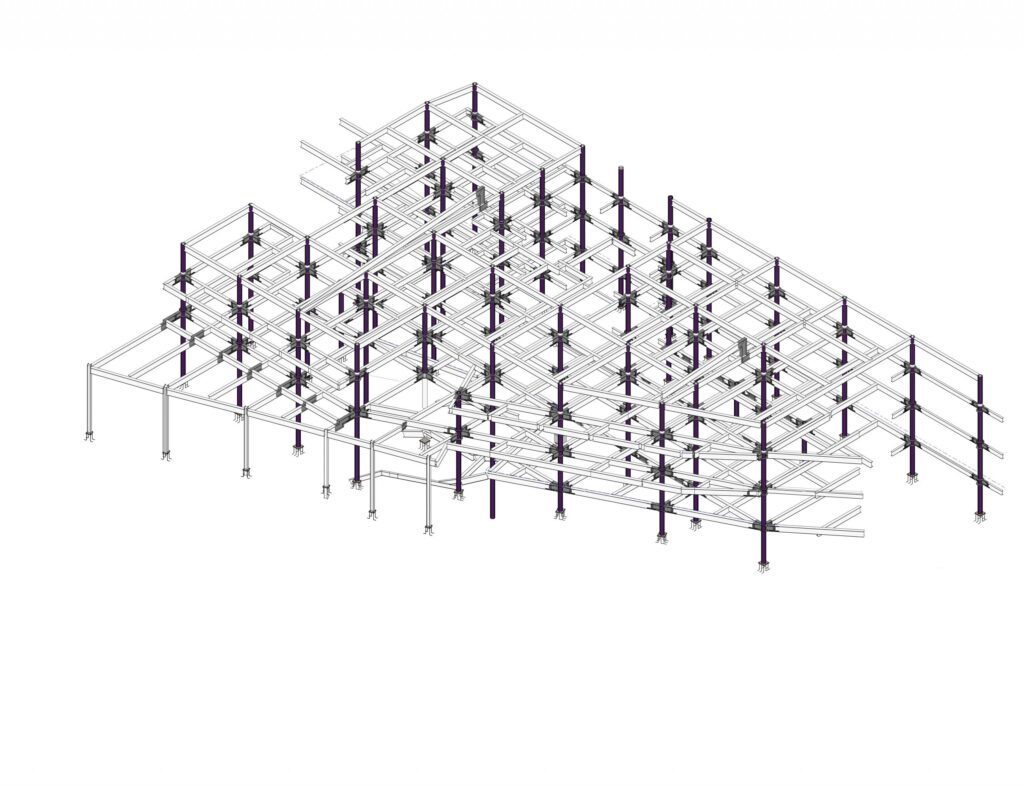

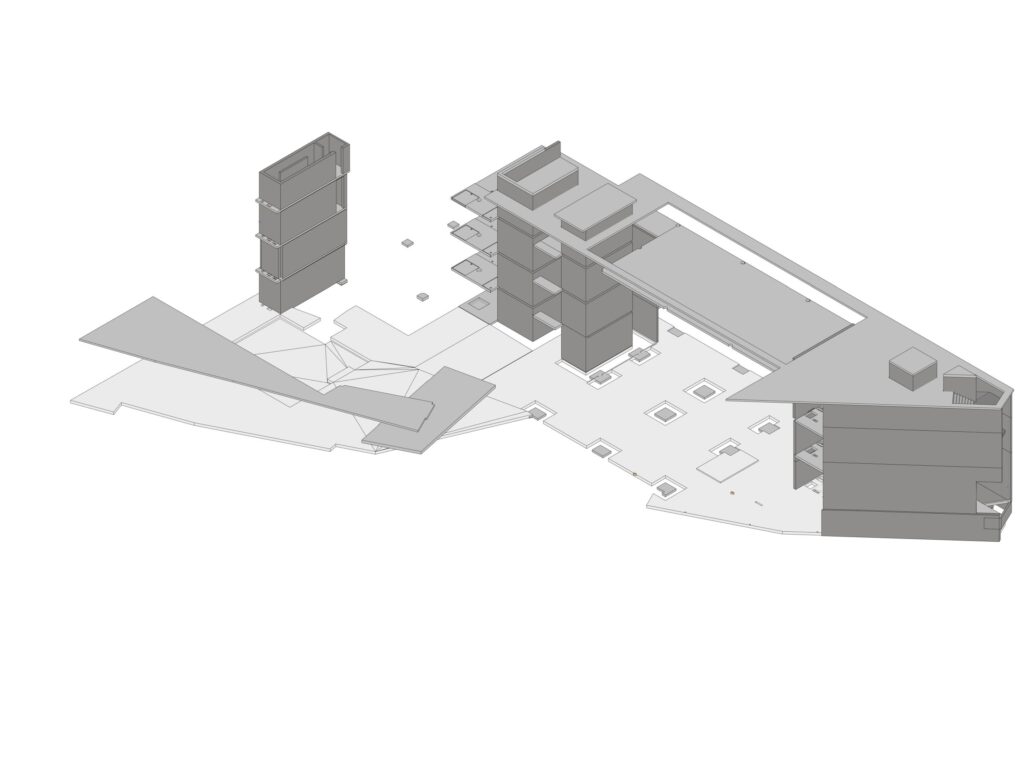

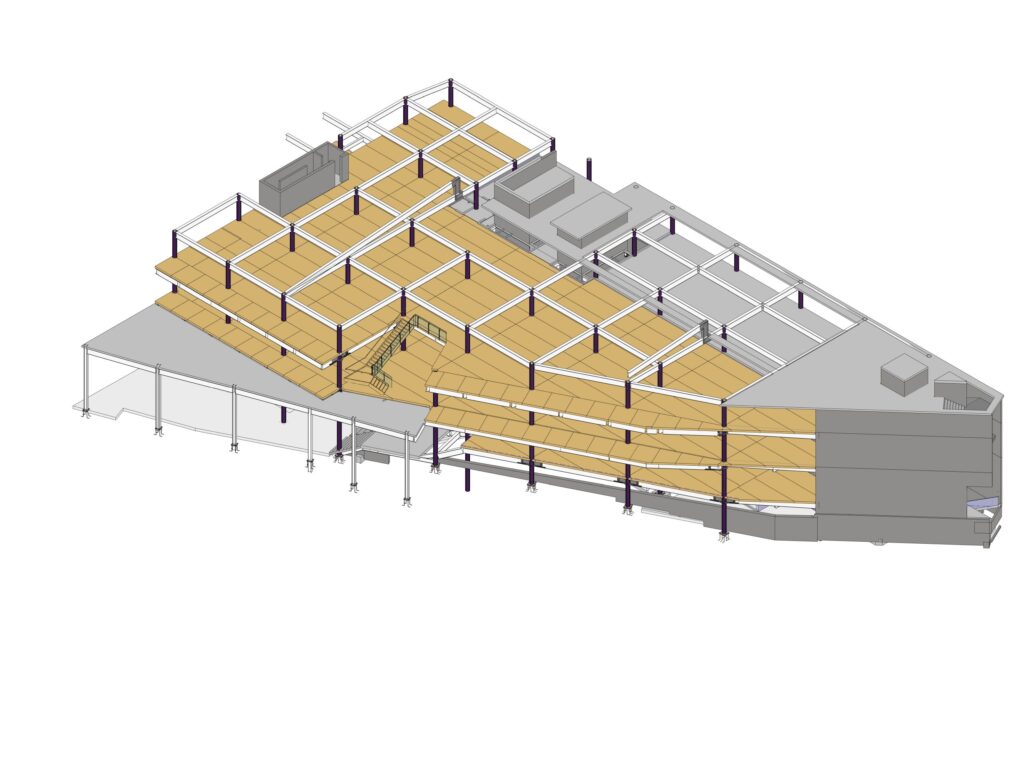

At SMU (Singapore Management University), a complex but extremely rewarding project, we had to work side by side with several teams from all over the world that had different roles in the construction of the building. Due to its hybrid-system nature, different materials had to be used. Concrete, steel, and timber, although different, had to “communicate” and work together perfectly since the main goal of the project was to get the most out of each one of them.

At this point, we can compare the necessary collaboration between teams to an orchestra where the different teams are the players and the BIM manager is the conductor. The role of the conductor (the BIM manager) is to communicate, organize and correctly manage all the teams and their inputs. The outcome of his work is to return an understandable, correctly updated, and duly tested BIM file (usually an .ifc file) before the building process so that on-site operations will be smooth and hassle-free just like a harmonious concert.

As mentioned before, the presence of more than one building material and therefore teams, will always inevitably contribute to a natural increase in complexity which translates into an increase in risk.

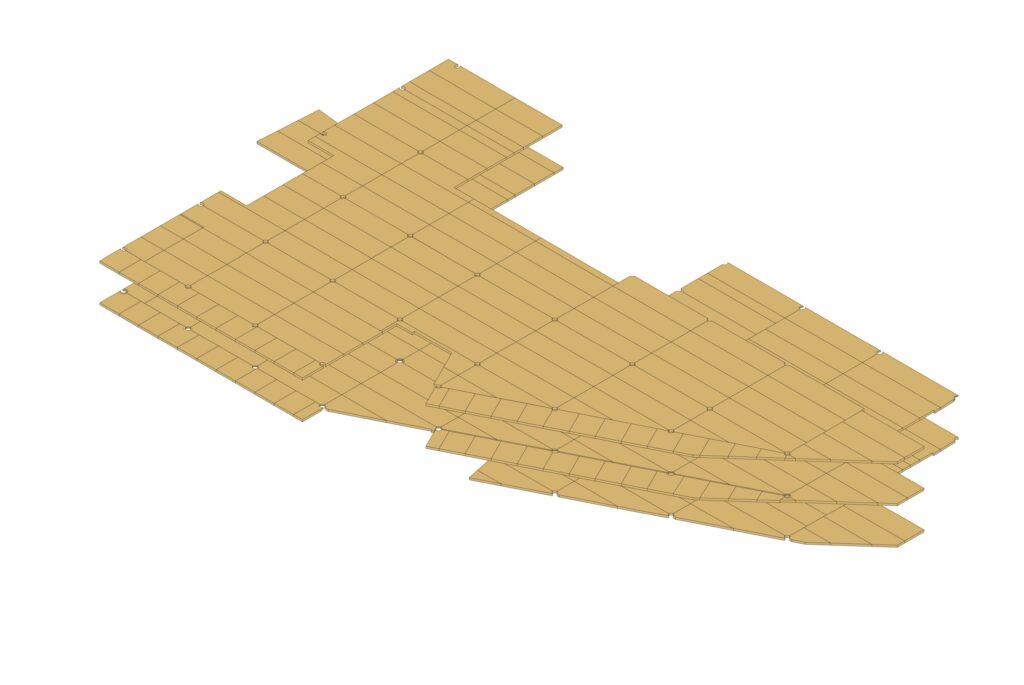

Here is where a skilled timber engineer can make the difference. Timber, a material with an increasingly central function in every new construction, is extremely versatile if is wisely designed and off-site prefabricated.

At Ergodomus, as you can see on our portfolio, we can work on various significant aspects in advance that contribute to lowering the risk and minimizing the possibility of errors and delays on site:

- designing with precision the best type of connections to use,

- deepening limits of CNC machinings in order to get the most out of the material,

- correctly work on, edit and read numerous types of documents/files,

- work on the logistics plan with a clear vision of the whole project pipeline,

- accurate detection of possible clashes,

- precise cost evaluation with careful analysis of the structure in all its aspects

- drastically reduce assembly time by favoring off-site instead of on-site

All these abilities confer us, and generally to timber engineers, a crucial role in building design and process. For over 15 years, our skilled team perfectly implemented all these abilities in our digital-based workflow permitting us to design and build structures in more than 16 countries and all 5 continents.