In the realm of timber engineering, precision reigns supreme.

Unlike some industries where room for error is tolerated, timber engineers like us understand that the phrase “about so precise” or “quite precise” holds no place in our vocabulary.

Each decision, each calculation, and every timber element designed demands a meticulous approach due to the cruciality of the transition from the design phase to the production phase and, finally, the assembly phase. This delicate but inevitable transition holds an important place in the project workflow since most of the time it determines the success of the whole project.

Timber engineers know that a minor misjudgment in design could lead to potential difficulties during assembly which, in turn, often result in more unwanted circumstances like severe slowing down or even stopping. This is the main reason why having the ability and, especially the experience to control every single detail, can ensure that our designs are structurally sound and seamlessly executable.

The projects we are working on are a perfect example of how far our mindset is from the concept of “about so”.

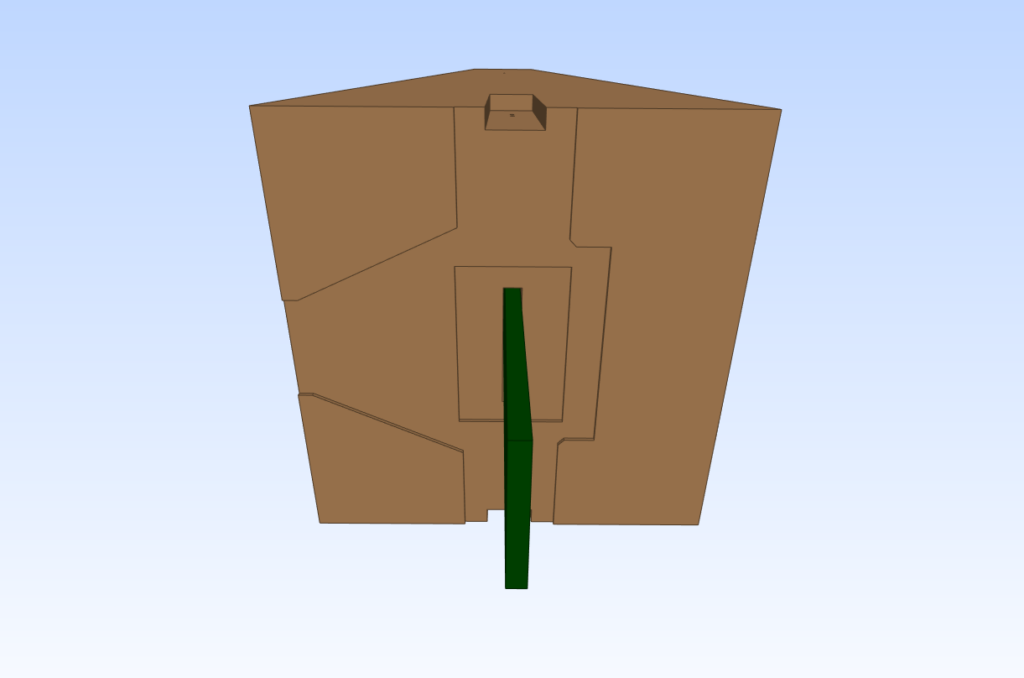

Let’s take for example this column, where every machining decision, due to its complexity and role in the structure has been taken in advance with absolute clarity and a holistic perspective.

At Ergodomus, all the CNC machining journey begins with the creation of a meticulously detailed digital model. This super powerful tool, if correctly implemented and constantly updated, permits to compare different solutions and find either the most cost-effective or the most appropriate solution for each individual project.

The better the digital model, the better the machine’s execution.

All of us are aware that even a 1mm discrepancy can have severe consequences on the assembly process. This understanding drives us to approach the production of CNC files with deep attention and precision to detail…even the smallest one.

What makes all of this even more incredible is that all these decisions, designs, and drawings were made several months before the start of the construction phase, and usually hundreds of kilometers away from where the structure will be installed.

This is to highlight the important fact that a timber engineer’s expertise isn’t just confined to CAD, IFC files, digital models, and CNC programming. Although these parts play a very important role, our attention must extend to the construction site, where the foresight we employ during the design phase becomes equally important.

Anticipating site conditions, comprehending the materials’ performance and behaviour, and foreseeing possible obstacles allow us to optimize our designs for on-site implementation: the pure essence of DfMA (design for manufacture and assembly). Indeed, besides allowing us to perfectly know how the elements are manufactured and machined, the DfMA approach that characterizes our entire workflow and projects, also permits us to determine how they are transported and assembled.

In conclusion, the “about so” and “quite precise” dangerous approach can only be avoided (and must be avoided) through a holistic approach that considers all the designing and construction phases and that makes absolute precision down to the last detail a cornerstone.