A couple of weeks ago we posted an impressive picture showing our director, Franco Piva, hugging a red spruce column while asking all our followers to guess how many CO2, eq tons that single mass timber element has sequestered.

The possible answers were four:

A. 3.7 tons

B. 0.9 tons

C. 1.7 tons

D. 6.1 tons

As always, only one is correct and in this case the correct answer, guessed by the majority of participants, was

C. 1.7 tons!

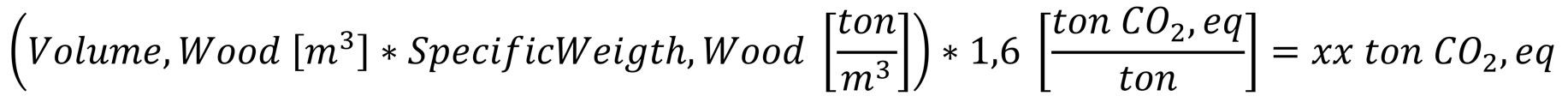

To calculate the tons of CO2 stored in that big boy we used a is a specific well known formula written and explained here below:

The first part in brackets calculates the weight in tons of the element (in our case the column was 0.6*0.6*6.6); the specific weight of the laminated wood is conventionally assumed to be equal to 500kg/mc (but on-site it can also reach 400kg/mc).

1.6 is the conversion factor: the 1.6 coefficient calculates tons of CO2 equivalent meaning that each ton of timber stores 1.6 tons of CO2.

So here we are with our correct answer…now, if you want to go even further, you can multiply it by the almost 900 hundred columns that will be installed and guess how much CO2 will be totally stored! Impressive, right?

The topic of co2 and the power of timber as a “carbon dioxide sequester” is extremely current so we thought it would have been interesting to take a deep dive into some CO2, timber engineering, and new timber building related aspects.

As everyone who works with timber knows, timber stands as a remarkable ally in reducing the building industry’s carbon footprint. Unlike concrete and steel, timber stores carbon dioxide rather than emitting it. Trees absorb CO2 during growth, which remains trapped in the timber when sustainably harvested and used in construction, acting as a carbon sink. In addition, timber production demands far less energy compared to concrete and steel, generating fewer emissions.

By choosing timber as a building material, we harness the power of nature’s carbon capture and storage mechanism helping to mitigate the CO2 impact of the (currently not so green) construction industry.

But there cannot be any timber structure without a timber engineer, and that’s where timber’s real potential gets enhanced.

At Ergodomus we worked super hard to find and optimize ways to contribute to the reduction of CO2 emissions since the very early stage of the project and, thanks to our technical expertise gained through these 20 years, we can list some of them:

- At Ergodomus we analyze the structural requirements of a building and determine the most efficient and appropriate use of timber. This strategy involves selecting the right types of timber products, such as engineered wood products like CLT, GLT, LVL, or glulam beams, that maximize strength while minimizing material consumption.

- Our dfma approach, which characterizes all our projects, permits us to assess the complete lifecycle of timber structures, considering factors like production, transportation, construction, use, and eventual disposal or recycling. This holistic view helps identify opportunities to reduce overall CO2 emissions at every stage.

- Minimizing waste, energy consumption, and emissions is the core of construction efficiency and something every timber engineer must consider when building with mass timber. We always take into consideration and prefer (when possible and convenient) prefabrication and off-site construction since they have a big positive impact on efficiency, order and cleanliness on site, and carbon emissions.

Finally, We want to thank everyone who participated, commented and reacted to our post. You all demonstrated that the impact of the construction industry on the environment is a serious issue that needs a revolution. And this revolution must be green, like trees, like timber.